Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

APPLICATIoN<br />

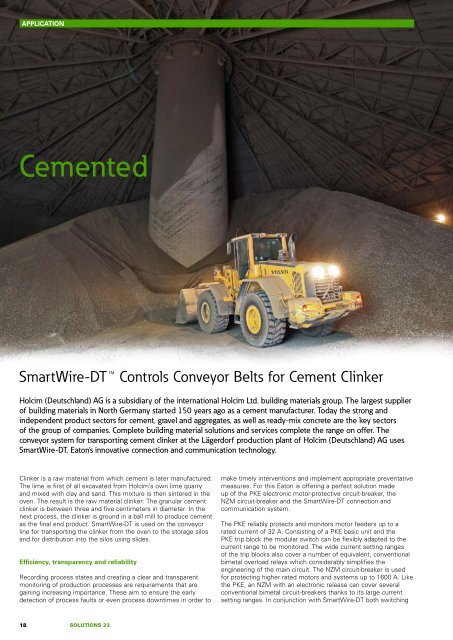

Cemented<br />

SmartWire-DT Controls Conveyor Belts <strong>for</strong> Cement Clinker<br />

Holcim (Deutschland) AG is a subsidiary of the international Holcim Ltd. building materials group. The largest supplier<br />

of building materials in North Germany started 150 years ago as a cement manufacturer. Today the strong and<br />

independent product sectors <strong>for</strong> cement, gravel and aggregates, as well as ready-mix concrete are the key sectors<br />

of the group of companies. Complete building material solutions and services complete the range on offer. The<br />

conveyor system <strong>for</strong> transporting cement clinker at the Lägerdorf production plant of Holcim (Deutschland) AG uses<br />

SmartWire-DT, Eaton’s innovative connection and communication technology.<br />

Clinker is a raw material from which cement is later manufactured.<br />

The lime is first of all excavated from Holcim’s own lime quarry<br />

and mixed with clay and sand. This mixture is then sintered in the<br />

oven. The result is the raw material clinker: The granular cement<br />

clinker is between three and five centimeters in diameter. In the<br />

next process, the clinker is ground in a ball mill to produce cement<br />

as the final end product. SmartWire-DT is used on the conveyor<br />

line <strong>for</strong> transporting the clinker from the oven to the storage silos<br />

and <strong>for</strong> distribution into the silos using slides.<br />

Efficiency, transparency and reliability<br />

Recording process states and creating a clear and transparent<br />

monitoring of production processes are requirements that are<br />

gaining increasing importance. These aim to ensure the early<br />

detection of process faults or even process downtimes in order to<br />

18<br />

SolutionS 23<br />

make timely interventions and implement appropriate preventative<br />

measures. For this Eaton is offering a perfect solution made<br />

up of the PKE electronic motor-protective circuit-breaker, the<br />

NZM circuit-breaker and the SmartWire-DT connection and<br />

communication system.<br />

The PKE reliably protects and monitors motor feeders up to a<br />

rated current of 32 A. Consisting of a PKE basic unit and the<br />

PKE trip block the modular switch can be flexibly adapted to the<br />

current range to be monitored. The wide current setting ranges<br />

of the trip blocks also cover a number of equivalent, conventional<br />

bimetal overload relays which considerably simplifies the<br />

engineering of the main circuit. The NZM circuit-breaker is used<br />

<strong>for</strong> protecting higher rated motors and systems up to 1600 A. Like<br />

the PKE, an NZM with an electronic release can cover several<br />

conventional bimetal circuit-breakers thanks to its large current<br />

setting ranges. In conjunction with SmartWire-DT both switching