Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

Export Requirements for Packaging Machines - Moeller

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INFo<br />

The Company: www.holcim.de/de<br />

Products: SmartWire-DT, PKE motor-protective<br />

circuit-breakers,MSC motor starters,<br />

NZM circuit-breakers<br />

Quicklink ID: ES2314 [www.moeller.net]<br />

devices only require a few simple operations to<br />

integrate into the control system. This gives you<br />

the option to transfer data about the state of<br />

the motor feeder and sections of the system to<br />

the higher-level controller. At the Lägerdorf plant<br />

NZM2 and motor starters (reversing starters<br />

and DOL starters) were each used with a PKE<br />

electronic motor-protective circuit-breaker.<br />

SmartWire-DT is based on standard fieldbus<br />

systems such as Profibus DP or CANopen,<br />

thus enabling a simple integration into standard<br />

PLC programming systems (such as CoDeSys<br />

and STEP7) and SCADA systems. Each<br />

slave on the SmartWire-DT is automatically<br />

assigned an address on the gateway at the<br />

push of a button and in the order in which the<br />

slaves are connected. The individual slaves<br />

are not activated until the address is called.<br />

The SmartWire-DT software (SWD-Assist)<br />

supports the user during planning. It offers help<br />

in correctly selecting the function elements,<br />

suggests accessories and carries out plausibility<br />

checks. For network configurations (such as<br />

Profibus configurations) the software can also be<br />

used to create specific device description files<br />

(GSD file) which are then simply imported into<br />

the appropriate programming system.<br />

SmartWire-DT keeps mounting and wiring<br />

requirements to a minimum. The continuous<br />

green SmartWire-DT cable is a striking feature in<br />

the switchboard. It provides the communication<br />

link between the required components.<br />

SmartWire-DT furthermore eliminates the need<br />

<strong>for</strong> the entire control system wiring – the single<br />

SmartWire-DT cable normally provides the power<br />

supply required. Conventional I/O modules are<br />

also not used since the I/O level on SmartWire-<br />

DT is directly integrated in the switchgear, thus<br />

totally excluding the possibility of faults.<br />

SmartWire-DT there<strong>for</strong>e opens up the problemfree<br />

control and reading of process data. With<br />

the PKE and NZM this consists of both simple<br />

Holcim (Deutschland) AG is a<br />

subsidiary of the international<br />

building materials group Holcim<br />

Ltd. The largest producer of<br />

building materials in North<br />

Germany, the company started<br />

150 years ago as a cement<br />

manufacturer. Today the strong<br />

and independent product sectors<br />

binary data such as switch positions and also<br />

more extensive messages such as causes of<br />

tripping and also analog data such as motor<br />

currents and the thermal load of a motor. The<br />

differentiated transmission of data provides<br />

users with new possibilities in monitoring<br />

and controlling processes. These range from<br />

increased transparency in manufacturing<br />

processes (monitoring) to the early detection<br />

of critical states or failures right through to<br />

preventative maintenance management.<br />

CoNCLuSIoN<br />

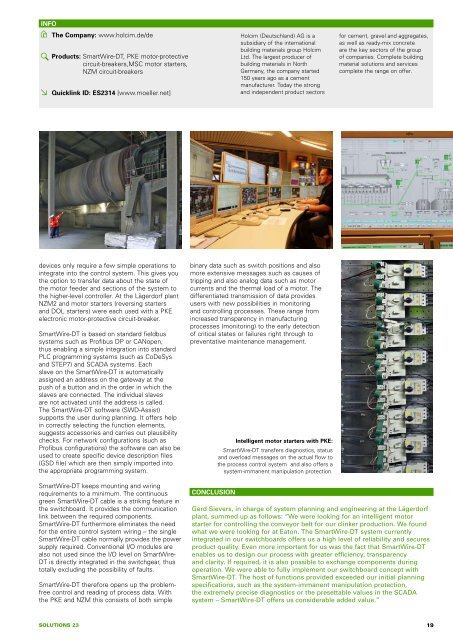

Intelligent motor starters with PKE:<br />

SmartWire-DT transfers diagnostics, status<br />

and overload messages on the actual flow to<br />

the process control system and also offers a<br />

system-immanent manipulation protection.<br />

<strong>for</strong> cement, gravel and aggregates,<br />

as well as ready-mix concrete<br />

are the key sectors of the group<br />

of companies. Complete building<br />

material solutions and services<br />

complete the range on offer.<br />

Gerd Sievers, in charge of system planning and engineering at the Lägerdorf<br />

plant, summed up as follows: “We were looking <strong>for</strong> an intelligent motor<br />

starter <strong>for</strong> controlling the conveyor belt <strong>for</strong> our clinker production. We found<br />

what we were looking <strong>for</strong> at Eaton. The SmartWire-DT system currently<br />

integrated in our switchboards offers us a high level of reliability and secures<br />

product quality. Even more important <strong>for</strong> us was the fact that SmartWire-DT<br />

enables us to design our process with greater efficiency, transparency<br />

and clarity. If required, it is also possible to exchange components during<br />

operation. We were able to fully implement our switchboard concept with<br />

SmartWire-DT. The host of functions provided exceeded our initial planning<br />

specifications, such as the system-immanent manipulation protection,<br />

the extremely precise diagnostics or the presettable values in the SCADA<br />

system – SmartWire-DT offers us considerable added value.”<br />

SolutionS 23 19