Condensed Catalog Featuring R410A Products Third Edition

Condensed Catalog Featuring R410A Products Third Edition

Condensed Catalog Featuring R410A Products Third Edition

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical leaflet<br />

Introduction<br />

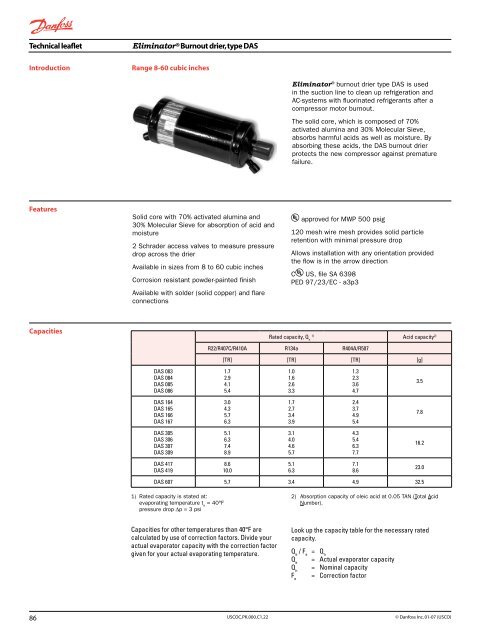

Eliminator® Burnout drier, type DAS<br />

Range 8-60 cubic inches<br />

Eliminator ® burnout drier type DAS is used<br />

in the suction line to clean up refrigeration and<br />

AC-systems with fluorinated refrigerants after a<br />

compressor motor burnout.<br />

The solid core, which is composed of 70%<br />

activated alumina and 30% Molecular Sieve,<br />

absorbs harmful acids as well as moisture. By<br />

absorbing these acids, the DAS burnout drier<br />

protects the new compressor against premature<br />

failure.<br />

Features<br />

Solid core with 70% activated alumina and<br />

30% Molecular Sieve for absorption of acid and<br />

moisture<br />

2 Schrader access valves to measure pressure<br />

drop across the drier<br />

Available in sizes from 8 to 60 cubic inches<br />

Corrosion resistant powder-painted finish<br />

Available with solder (solid copper) and flare<br />

connections<br />

approved for MWP 500 psig<br />

120 mesh wire mesh provides solid particle<br />

retention with minimal pressure drop<br />

Allows installation with any orientation provided<br />

the flow is in the arrow direction<br />

C US, file SA 6398<br />

PED 97/23/EC - a3p3<br />

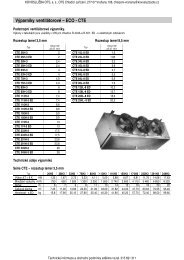

Capacities<br />

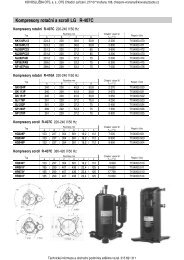

Rated capacity, Q n 1) Acid capacity 2)<br />

R22/R407C/<strong>R410A</strong> R134a R404A/R507<br />

[TR] [TR] [TR] [g]<br />

DAS 083<br />

DAS 084<br />

DAS 085<br />

DAS 086<br />

1.7<br />

2.9<br />

4.1<br />

5.4<br />

1.0<br />

1.6<br />

2.6<br />

3.3<br />

1.3<br />

2.3<br />

3.6<br />

4.7<br />

3.5<br />

DAS 164<br />

DAS 165<br />

DAS 166<br />

DAS 167<br />

3.0<br />

4.3<br />

5.7<br />

6.3<br />

1.7<br />

2.7<br />

3.4<br />

3.9<br />

2.4<br />

3.7<br />

4.9<br />

5.4<br />

7.8<br />

DAS 305<br />

DAS 306<br />

DAS 307<br />

DAS 309<br />

5.1<br />

6.3<br />

7.4<br />

8.9<br />

3.1<br />

4.0<br />

4.6<br />

5.7<br />

4.3<br />

5.4<br />

6.3<br />

7.7<br />

16.2<br />

DAS 417<br />

DAS 419<br />

8.6<br />

10.0<br />

5.1<br />

6.3<br />

7.1<br />

8.6<br />

23.0<br />

DAS 607 5.7 3.4 4.9 32.5<br />

1) Rated capacity is stated at:<br />

evaporating temperature t e<br />

= 40°F<br />

pressure drop ∆p = 3 psi<br />

2) Absorption capacity of oleic acid at 0.05 TAN (Total Acid<br />

Number).<br />

Capacities for other temperatures than 40°F are<br />

calculated by use of correction factors. Divide your<br />

actual evaporator capacity with the correction factor<br />

given for your actual evaporating temperature.<br />

Look up the capacity table for the necessary rated<br />

capacity.<br />

Q e<br />

/ F e<br />

= Q n<br />

Q e<br />

= Actual evaporator capacity<br />

Q n<br />

= Nominal capacity<br />

= Correction factor<br />

F e<br />

86 USCOC.PK.000.C1.22 © Danfoss Inc. 01-07 (USCO)