D R I E – D Lagertechniek bv DATA SHEETS

D R I E – D Lagertechniek bv DATA SHEETS

D R I E – D Lagertechniek bv DATA SHEETS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DRIE-D <strong>Lagertechniek</strong> <strong>bv</strong><br />

the right perspective<br />

Kiotoweg 120, 3047 BG, Rotterdam, NL<br />

telephone: (+31) 10 - 462 07 00<br />

telefax: (+31) 10 - 462 07 07<br />

E-mail: mail@drie-d.nl<br />

internet: www.drie-d.nl<br />

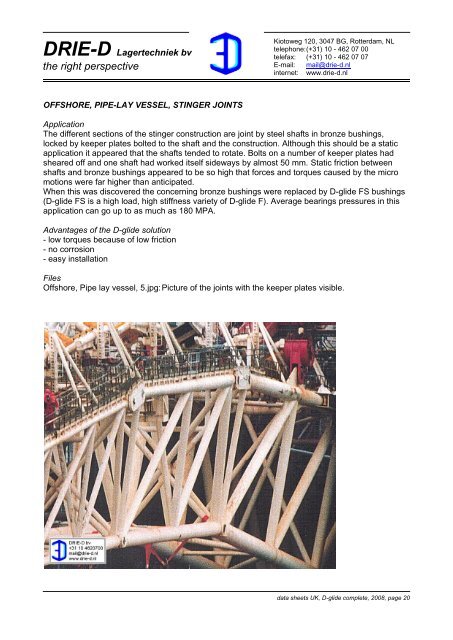

OFFSHORE, PIPE-LAY VESSEL, STINGER JOINTS<br />

Application<br />

The different sections of the stinger construction are joint by steel shafts in bronze bushings,<br />

locked by keeper plates bolted to the shaft and the construction. Although this should be a static<br />

application it appeared that the shafts tended to rotate. Bolts on a number of keeper plates had<br />

sheared off and one shaft had worked itself sideways by almost 50 mm. Static friction between<br />

shafts and bronze bushings appeared to be so high that forces and torques caused by the micro<br />

motions were far higher than anticipated.<br />

When this was discovered the concerning bronze bushings were replaced by D-glide FS bushings<br />

(D-glide FS is a high load, high stiffness variety of D-glide F). Average bearings pressures in this<br />

application can go up to as much as 180 MPA.<br />

Advantages of the D-glide solution<br />

- low torques because of low friction<br />

- no corrosion<br />

- easy installation<br />

Files<br />

Offshore, Pipe lay vessel, 5.jpg: Picture of the joints with the keeper plates visible.<br />

data sheets UK, D-glide complete, 2008, page 20