High Performance Solar Cells Exceeding 17 ... - ISC Konstanz

High Performance Solar Cells Exceeding 17 ... - ISC Konstanz

High Performance Solar Cells Exceeding 17 ... - ISC Konstanz

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Average solar cell efficiency [%]<br />

Lifetime [s]<br />

texturisation all samples were processed by POCl 3<br />

diffusion, PECVD SiN x deposition, full Al BSF screen<br />

printing, Ag finger grid screen printing and firing<br />

through. Measurements of the solar cell parameters were<br />

carried out and the reverse current was determined at<br />

-14.5V to see the influence of the texturisation on both<br />

results.<br />

3 RESULTS<br />

3.1 Results of diffusion optimization<br />

Minority carrier lifetime measurements were<br />

performed to screen the feedstock quality of the<br />

investigated ingots. Therefore the saw damage of wafers<br />

from the center bricks of each ingot was removed and the<br />

samples were passivated by a PECVD SiN x . The<br />

lifetimes of those samples were determined using QSSPC<br />

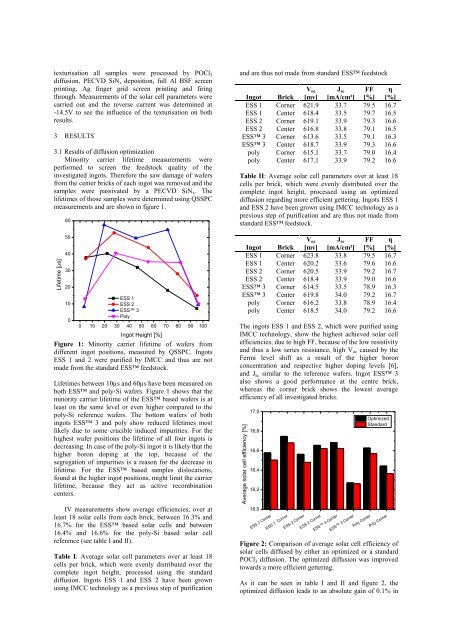

measurements and are shown in figure 1.<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

ESS 1<br />

ESS 2<br />

ESS 3<br />

Poly<br />

0 10 20 30 40 50 60 70 80 90 100<br />

Ingot Height [%]<br />

Figure 1: Minority carrier lifetime of wafers from<br />

different ingot positions, measured by QSSPC. Ingots<br />

ESS 1 and 2 were purified by IMCC and thus are not<br />

made from the standard ESS feedstock.<br />

Lifetimes between 10µs and 60µs have been measured on<br />

both ESS and poly-Si wafers. Figure 1 shows that the<br />

minority carrier lifetime of the ESS based wafers is at<br />

least on the same level or even higher compared to the<br />

poly-Si reference wafers. The bottom wafers of both<br />

ingots ESS 3 and poly show reduced lifetimes most<br />

likely due to some crucible induced impurities. For the<br />

highest wafer positions the lifetime of all four ingots is<br />

decreasing. In case of the poly-Si ingot it is likely that the<br />

higher boron doping at the top, because of the<br />

segregation of impurities is a reason for the decrease in<br />

lifetime. For the ESS based samples dislocations,<br />

found at the higher ingot positions, might limit the carrier<br />

lifetime, because they act as active recombination<br />

centers.<br />

and are thus not made from standard ESS feedstock<br />

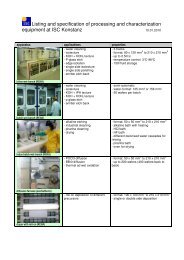

Ingot Brick<br />

V oc<br />

[mv]<br />

J sc<br />

[mA/cm²]<br />

FF<br />

[%]<br />

η<br />

[%]<br />

ESS 1 Corner 621.9 33.7 79.5 16.7<br />

ESS 1 Center 618.4 33.5 79.7 16.5<br />

ESS 2 Corner 619.1 33.9 79.3 16.6<br />

ESS 2 Center 616.8 33.8 79.1 16.5<br />

ESS 3 Corner 613.6 33.5 79.1 16.3<br />

ESS 3 Center 618.7 33.9 79.3 16.6<br />

poly Corner 615.1 33.7 79.0 16.4<br />

poly Center 6<strong>17</strong>.1 33.9 79.2 16.6<br />

Table II: Average solar cell parameters over at least 18<br />

cells per brick, which were evenly distributed over the<br />

complete ingot height, processed using an optimized<br />

diffusion regarding more efficient gettering. Ingots ESS 1<br />

and ESS 2 have been grown using IMCC technology as a<br />

previous step of purification and are thus not made from<br />

standard ESS feedstock.<br />

Ingot Brick<br />

V oc<br />

[mv]<br />

J sc<br />

[mA/cm²]<br />

FF<br />

[%]<br />

η<br />

[%]<br />

ESS 1 Corner 623.8 33.8 79.5 16.7<br />

ESS 1 Center 620.2 33.6 79.6 16.6<br />

ESS 2 Corner 620.5 33.9 79.2 16.7<br />

ESS 2 Center 618.4 33.9 79.0 16.6<br />

ESS 3 Corner 614.5 33.5 78.9 16.3<br />

ESS 3 Center 619.8 34.0 79.2 16.7<br />

poly Corner 616.2 33.8 78.9 16.4<br />

poly Center 618.5 34.0 79.2 16.6<br />

The ingots ESS 1 and ESS 2, which were purified using<br />

IMCC technology, show the highest achieved solar cell<br />

efficiencies, due to high FF, because of the low resistivity<br />

and thus a low series resistance, high V oc caused by the<br />

Fermi level shift as a result of the higher boron<br />

concentration and respective higher doping levels [6],<br />

and J sc similar to the reference wafers. Ingot ESS 3<br />

also shows a good performance at the centre brick,<br />

whereas the corner brick shows the lowest average<br />

efficiency of all investigated bricks.<br />

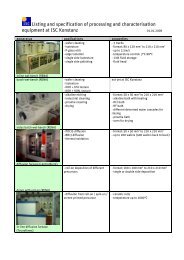

<strong>17</strong>,0<br />

16,8<br />

16,6<br />

16,4<br />

16,2<br />

Optimized<br />

Standard<br />

IV measurements show average efficiencies, over at<br />

least 18 solar cells from each brick, between 16.3% and<br />

16.7% for the ESS based solar cells and between<br />

16.4% and 16.6% for the poly-Si based solar cell<br />

reference (see table I and II).<br />

Table I: Average solar cell parameters over at least 18<br />

cells per brick, which were evenly distributed over the<br />

complete ingot height, processed using the standard<br />

diffusion. Ingots ESS 1 and ESS 2 have been grown<br />

using IMCC technology as a previous step of purification<br />

16,0<br />

ESS 1 Center<br />

ESS 1 Corner<br />

ESS 2 Center<br />

ESS 2 Corner<br />

ESS 3 Center<br />

ESS 3 Corner<br />

Poly Center<br />

Poly Corner<br />

Figure 2: Comparison of average solar cell efficiency of<br />

solar cells diffused by either an optimized or a standard<br />

POCl 3 diffusion. The optimized diffusion was improved<br />

towards a more efficient gettering.<br />

As it can be seen in table I and II and figure 2, the<br />

optimized diffusion leads to an absolute gain of 0.1% in