Environment Report - Santos

Environment Report - Santos

Environment Report - Santos

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

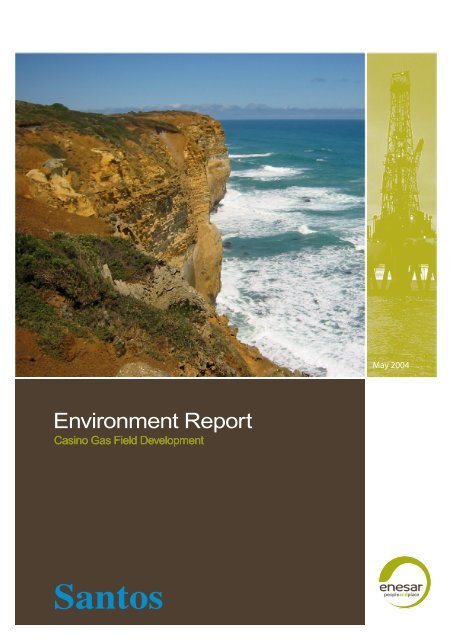

<strong>Environment</strong> <strong>Report</strong><br />

Casino Gas Field Development<br />

May 2004

Casino Gas Field Development<br />

<strong>Environment</strong> <strong>Report</strong><br />

May 2004<br />

CR 1086_ 7_v2<br />

Prepared by: Enesar Consulting Pty Ltd<br />

124 Camberwell Road Hawthorn East Victoria Australia 3123<br />

p 61-3-9882 3555 f 61-3-9882 3533<br />

e office@enesar.com.au www enesar.com.au

Preface<br />

The Casino Gas Field Development requires approval under the Commonwealth Petroleum (Submerged Lands) Act<br />

1967, the Victorian Petroleum (Submerged Lands) Act 1982 and the Victorian Pipelines Act 1967. This <strong>Environment</strong><br />

<strong>Report</strong> (ER) has been lodged in support of an application for a Pipeline Permit under the Victorian Pipelines Act 1967.<br />

Public Display and Availability of the ER<br />

Copies of the ER will be on display and available during the exhibition period for public review at the following locations:<br />

Department of Sustainability and <strong>Environment</strong>, Customer Information Centre<br />

Nauru House, 80 Collins Street, MELBOURNE, Victoria 3000<br />

Department of Primary Industries, Minerals and Petroleum Reference Centre<br />

Level 8, 240 Victoria Parade, EAST MELBOURNE, Victoria 3002<br />

Port Campbell Visitor Information Centre<br />

26 Morris Street, PORT CAMPBELL, Victoria 3269<br />

Corangamite Shire Civic Centre<br />

181 Manifold Street, CAMPERDOWN, Victoria 3260<br />

Department of Sustainability and <strong>Environment</strong><br />

78 Henna Street, WARRNAMBOOL, Victoria 3280<br />

Department of Sustainability and <strong>Environment</strong><br />

83 Gellibrand Street, COLAC, Victoria 3250<br />

Electronic copies may be downloaded from the <strong>Santos</strong> website at: http//:www.santos.com.au.<br />

Queries and requests for hard copies or electronic copies on CD should be directed to:<br />

Catriona McTaggart, Casino <strong>Environment</strong>al Adviser<br />

<strong>Santos</strong> Ltd, GPO Box 2319, ADELAIDE, South Australia 5001. Telephone: 08-8224 7894<br />

Opportunity for Public Comment on the ER<br />

The ER provides a basis for the public to comment on the proposal, the environmental impacts and proposed mitigation<br />

measures.<br />

Public submissions will be considered by the Department of Primary Industries (DPI) in accordance with the Victorian<br />

Pipelines Act 1967.<br />

Lodging a Submission<br />

In your submission, you will need to:<br />

• Identify the proposal on which you are commenting and provide your name and address.<br />

• Where relevant, identify any special interest you have in the proposal.<br />

• If you are commenting on specific text within the ER, mention the section number and heading used in the ER.<br />

Written submissions should be sent to:<br />

Phil Roberts, Director, Minerals and Petroleum Victoria<br />

Department of Primary Industries, PO Box 500, EAST MELBOURNE, Victoria 3002<br />

Deadline for Lodging a Submission<br />

Written submissions must be received by close of business 30 days after the date of the pipeline permit application<br />

public notice.<br />

Further Information<br />

Further information regarding the Casino Gas Field Development can be obtained by contacting Catriona McTaggart<br />

(details above).

Executive Summary<br />

Executive Summary<br />

1. Introduction<br />

Project and Proponent<br />

<strong>Santos</strong> Ltd (<strong>Santos</strong>) proposes to develop<br />

the Casino gas field approximately 30<br />

km offshore from Port Campbell on Victoria’s<br />

southwest coast. The Casino Gas<br />

Field Development is a AUD$200 million<br />

project and comprises subsea installations<br />

and pipeline development that will<br />

carry gas from offshore wells to an existing<br />

TXU gas processing facility near Port<br />

Campbell.<br />

Joint venture partners in the Casino Gas<br />

Field Development with <strong>Santos</strong> (50% interest),<br />

include Peedamullah Petroleum<br />

Pty Ltd (Australian Worldwide Exploration<br />

Limited) (25% interest) and Mitwell<br />

Energy Resources Pty Limited (Mitsui &<br />

Co. (Australia) Ltd) (25% interest).<br />

Project Justification<br />

The demand for natural gas is increasing<br />

steadily. <strong>Santos</strong>, as operator of the<br />

Commonwealth exploration permit area<br />

Vic/P44, is obliged to explore for petroleum<br />

resources and, if feasible, develop<br />

any discovered resources to meet consumer<br />

demand.<br />

Gas from the Casino gas field is earmarked<br />

for use by Victorian consumers<br />

during 2006 as a supplement to existing<br />

Victorian gas reserves catering for the<br />

predicted increase in demand. In the<br />

medium-term and longer-term, the gas<br />

will be available for distribution into the<br />

Victorian and South Australian gas markets<br />

but the gas may also be temporarily<br />

stored in depleted underground gas reservoirs,<br />

awaiting withdrawal during periods<br />

of peak demand.<br />

Other potential benefits of the project<br />

include:<br />

• Employment opportunities.<br />

• Direct and indirect commercial benefits.<br />

• Provision of an alternative independent<br />

supply of gas to supplement existing<br />

gas reserves and further<br />

improve security of supply and reliability.<br />

• Increasing inter-basin competition<br />

between gas producers.<br />

• Increased use of the TXU gas<br />

processing and storage facility.<br />

• Potential for reduction in greenhouse<br />

gas emissions (compared to the use<br />

of alternative fossil fuels).<br />

Regulatory Framework<br />

The proposed Casino Gas Field Development<br />

falls within three jurisdictions including<br />

Commonwealth and Victorian<br />

waters and onshore Victoria. Consequently,<br />

permits and licences are required<br />

respectively under the<br />

Commonwealth Petroleum (Submerged<br />

Lands) Act 1967, the Victorian Petroleum<br />

(Submerged Lands) Act 1982 and<br />

the Victorian Pipelines Act 1967.<br />

The Minister for Planning has determined<br />

that the magnitude and significance of<br />

potential impacts would not necessitate<br />

the preparation of an environment effects<br />

statement. Accordingly, this <strong>Environment</strong><br />

<strong>Report</strong> has been prepared in<br />

support of the pipeline permit application<br />

under the Pipelines Act 1967 and is available<br />

for public review and comment.<br />

In December 2003, the project was determined<br />

to be a controlled action under<br />

the <strong>Environment</strong> Protection and Biodiversity<br />

Conservation Act 1999 (EPBC<br />

Act) based on the lack of certainty in<br />

construction timing and pipeline alignments<br />

and therefore potential impacts<br />

upon blue whales, and to a lesser degree,<br />

listed terrestrial flora and fauna.<br />

The subsequent Commonwealth environmental<br />

assessment under the EPBC Act<br />

has been undertaken through separate<br />

documentation, i.e., Preliminary Documentation.<br />

Stakeholder Consultation<br />

<strong>Santos</strong> has been consulting with relevant<br />

stakeholders on an ongoing basis since<br />

2000 when they commenced exploration<br />

and production activities in southwest<br />

Victoria. With the proposed Casino Gas<br />

Field Development, <strong>Santos</strong> embarked on<br />

a consultation program that focused on<br />

stakeholders potentially affected by the<br />

project, in particular landowners and<br />

commercial fishers, but also local interest<br />

groups. Information from stakeholders<br />

has been used to enhance the design<br />

and operation of the project.<br />

Stakeholder consultation will continue<br />

through the approvals process and the<br />

detailed design, construction, operation<br />

and decommissioning phases of the<br />

project.<br />

2. The Project<br />

Overview<br />

The Casino gas field was discovered in<br />

September 2002. It contains estimated<br />

recoverable reserves of 211 billion cubic<br />

feet (bcf) of natural gas and has an expected<br />

field life of up to 12 years. The<br />

Casino Gas Field Development comprises<br />

the offshore production of gas and<br />

its transportation to shore in a dedicated<br />

pipeline to the existing TXU Western<br />

Underground Gas Storage (WUGS) facility<br />

at Iona near Port Campbell for<br />

processing (Figure 1). Specifically, the<br />

development comprises:<br />

• Drilling two offshore development<br />

wells.<br />

• Installation of wellheads on the seafloor.<br />

No structures will be visible from<br />

shore.<br />

• Installation of a subsea pipeline and<br />

control umbilical (each approximately<br />

36.7 km long) on the sea floor to<br />

transfer gas from the wells to shore.<br />

• Horizontal directional drilling (HDD)<br />

of the shore crossing from farmland<br />

outside the Port Campbell National<br />

Park.<br />

• Construction of a buried onshore<br />

pipeline (11.5 km in length) from the<br />

HDD shore crossing to the TXU<br />

Casino Gas Field Development<br />

v

Executive Summary<br />

TXU WUGS<br />

facility<br />

Raw gas pipeline<br />

HDD pipeline section<br />

Optic fibre cable<br />

MEG pipeline<br />

Umbilical line<br />

Mainline valve site<br />

Onshore pipeline<br />

(11.5 km)<br />

HDD shore crossing<br />

(1.6 km)<br />

Casino 5<br />

Casino 4<br />

Subsea pipeline and control umbilical<br />

(36.7 km)<br />

2 subsea wells<br />

Figure 1<br />

Casino Gas Field Development schematic<br />

WUGS facility. A mainline valve site<br />

will be located in farmland near the<br />

coast.<br />

• Processing of the gas by TXU at the<br />

WUGS facility prior to distribution to<br />

Victorian and interstate customers<br />

through the existing pipeline network.<br />

The raw gas has very low carbon dioxide<br />

content (less than 1%) and no detectable<br />

sulfur oxides or nitrous oxides, and<br />

is therefore within sales gas specifications.<br />

Small quantities of liquids, including water<br />

and condensate may be transported<br />

to shore with the gas and these will be<br />

removed at the TXU WUGS facility. Condensate<br />

will be transported to an existing<br />

refinery by road tanker (estimated at<br />

two or three trucks per week for the first<br />

two years, then delcining to about one<br />

per week thereafter).<br />

Pipeline Route Selection<br />

<strong>Santos</strong> has implemented a pipeline route<br />

selection process that considered social,<br />

environmental, engineering and financial<br />

criteria. Foremost in this process was<br />

the desire to find a pipeline alignment<br />

that is acceptable to local landowners.<br />

The key phases in the route selection<br />

process were:<br />

• Shore crossing site.<br />

• Offshore pipeline alignment.<br />

• Onshore pipeline alignment.<br />

Shore Crossing. The selection of the<br />

preferred option for the shore crossing<br />

was the primary determinant in the overall<br />

alignment of the pipeline from the<br />

Casino gas field to the TXU WUGS facility.<br />

Following preliminary engineering and<br />

environmental assessments and consultation<br />

with key stakeholders, <strong>Santos</strong> identified<br />

Two Mile Bay as the preferred shore<br />

crossing location (Figure 2). Key benefits<br />

of this location are:<br />

• The consolidation of shore crossings<br />

for the Minerva, Otway and Casino<br />

gas fields to one area.<br />

• From the HDD site, it is possible to<br />

locate the offshore pipeline route in<br />

predominantly sandy seabed, thereby<br />

avoiding nearshore reef habitat and<br />

minimising impacts on offshore reefs<br />

and commercial fishing grounds.<br />

<strong>Santos</strong> proposes to locate the HDD site<br />

outside of the Port Campbell National<br />

Park to the west of BHP Billiton’s Minerva<br />

Project HDD site. The drill will then extend<br />

beneath the surface of the Port<br />

Campbell National Park (but through the<br />

park, as tenure extends to the centre of<br />

the earth) to exit approximately 1,225 m<br />

offshore, beyond the surf zone and<br />

nearshore reef habitat, at approximately<br />

the 15 to 16 m water depth. The total drill<br />

length would be 1,573 m.<br />

Offshore Pipeline. Having selected Two<br />

Mile Bay as the preferred shore crossing<br />

site, it was necessary to verify that the<br />

offshore seabed conditions were suitable<br />

for a pipeline. Preliminary bathymetric<br />

data obtained from <strong>Santos</strong>’ earlier<br />

seismic exploration survey and published<br />

seabed mapping identified several areas<br />

of potentially problematic seafloor<br />

features. Commercial fishers later confirmed<br />

the existence of these features.<br />

<strong>Santos</strong> consequently selected an align-<br />

vi<br />

Casino Gas Field Development

Executive Summary<br />

640 000 650 000 660 000 670 000<br />

AUSTRALIA<br />

VICTORIA<br />

Flaxman's Hill<br />

North Paaratte<br />

Gas Plant<br />

Heytesbury<br />

Gas Plant<br />

Proposed<br />

Otway Gas<br />

Project Plant<br />

Lovers Nook<br />

Campbells Creek<br />

Curdies<br />

Inlet<br />

Peterborough<br />

N<br />

VICTORIA<br />

Melbourne<br />

N<br />

NEW SOUTH WALES<br />

Tasman<br />

Sea<br />

Minerva Gas<br />

Plant<br />

10m<br />

20m<br />

30m<br />

Bass Strait<br />

0 km<br />

100<br />

Port Campbell<br />

40m<br />

Newfield Bay<br />

HDD shore<br />

crossing site<br />

50m<br />

Two Mile Bay<br />

TXU WUGS<br />

Facility<br />

60m<br />

Minerva Pipeline<br />

N<br />

0 km 5<br />

70m<br />

Map projection: AMG, ADG 66 Zone 54<br />

Minerva<br />

Gas<br />

Well<br />

Proposed Otway gas pipeline<br />

Bay of Islands Coastal Park<br />

Peterborough Coastal Reserve<br />

Port Campbell National Park<br />

Preferred Casino pipeline alignment<br />

HDD section<br />

Existing gas pipeline<br />

Proposed Otway Gas pipeline<br />

Casino gas reservoir<br />

Gas well<br />

Bathymetry<br />

Casino 5 Casino 6<br />

Casino 4<br />

Figure 2 Casino Gas Field Development pipeline alignment<br />

5 710 000 5 720 000 5 730 000<br />

Casino Gas Field Development<br />

vii

Executive Summary<br />

ment from the Casino gas field to the<br />

preferred shore crossing location that<br />

would traverse predominantly sandy seabed,<br />

thereby avoiding nearshore reef<br />

habitat and minimising impacts on offshore<br />

reefs and commercial fishing<br />

grounds.<br />

<strong>Santos</strong> then commissioned a bathymetry<br />

survey so that these features could<br />

be characterised and precisely located<br />

and a subsea pipeline route could be<br />

selected that avoids these features,<br />

where practicable (Figure 3).<br />

Onshore Pipeline. <strong>Santos</strong> investigated<br />

several potential onshore pipeline route<br />

options aimed at identifying an alignment<br />

that met environmental, social and technical<br />

criteria.<br />

The preferred onshore pipeline alignment<br />

was selected to traverse farmland and<br />

avoid remnant native vegetation, minimise<br />

impacts to farm operations and future<br />

land development, avoid highly<br />

unstable terrain in the Campbells Creek<br />

valley and cross Campbells Creek adjacent<br />

to existing pipeline easements. Following<br />

minor realignment to follow<br />

fencelines, the preferred alignment received<br />

in-principle agreement from<br />

landholders, subject to the negotiation of<br />

easement agreements. The preferred<br />

onshore pipeline alignment follows existing<br />

easements or fence lines for approximately<br />

90% of its 11.5 km length.<br />

Figure 4 shows the route traversed by<br />

the preferred onshore pipeline alignment<br />

and illustrates the typical land uses along<br />

the preferred pipeline route.<br />

Construction<br />

Construction is scheduled to commence<br />

in January 2005 to enable commercial<br />

operation and first gas by January 2006.<br />

Offshore drilling and completion of the<br />

two wells will take approximately two to<br />

three months. Mobilisation of the drill rig<br />

is scheduled for January 2005 to enable<br />

commencement of drilling in late January/early<br />

February 2005.<br />

The offshore pipeline will be installed by<br />

either pipelay barge or pipe reel-lay vessel<br />

and is scheduled to commence in<br />

November 2005 and take approximately<br />

20 days, subject to weather conditions.<br />

The installation of the shore crossing is<br />

expected to take about seven months,<br />

and is scheduled to take place between<br />

January and July 2005. This incorporates<br />

setting up the HDD site, mobilising<br />

equipment to the site, drilling and reaming<br />

the two holes (gas pipeline and umbilical<br />

lines), installation of the pipe and umbilical,<br />

grouting and demobilisation. The end<br />

of the pipeline will be rigged up with a<br />

‘pullhead’ ready for pick up by the pipelay<br />

vessel and connection to the offshore<br />

pipeline.<br />

Onshore pipeline installation is undertaken<br />

as a production line, with multiple<br />

specialist crews, that progresses along<br />

a cleared and graded 24-m construction<br />

right-of-way (ROW), and involves pipe<br />

stringing, trenching, bending, welding,<br />

installation, backfilling and rehabilitation<br />

of the ROW on completion. The duration<br />

of onshore construction at any one location<br />

is expected to take approximately<br />

eight weeks from clear and grade to<br />

trench backfill. The ROW is then<br />

revegetated with appropriate seed mixes.<br />

Total onshore pipeline construction is<br />

expected to take about six months including<br />

mainline valve (MLV) installation<br />

and easement reinstatement. The legal<br />

easement for Casino pipeline operations<br />

is 15 m.<br />

3. Project Setting and Issues<br />

Project Setting<br />

The offshore portion of the project area<br />

extends from the Casino gas field to the<br />

pipeline shore crossing at Two Mile Bay.<br />

The characteristics of the marine environment<br />

and coastline of this region include<br />

very steep to moderate offshore<br />

gradients, high wave energy and cold<br />

temperature waters.<br />

Migratory marine birds and whale species<br />

occur in the project area, several of<br />

which are listed as threatened under the<br />

EPBC Act. A variety of marine species<br />

including reef-dependent and deep-water<br />

species are commercially harvested<br />

in the vicinity of the proposed development.<br />

A component of the onshore project areas<br />

lies within the Port Campbell National<br />

Park (in that the HDD will extend<br />

through, but beneath the surface of the<br />

Park), which is listed by the Register of<br />

National Estate (RNE) as an area of national<br />

significance and is the only conservation<br />

reserve within the onshore<br />

project area. The area is mostly undulating<br />

terrain, the main geomorphological<br />

features of which include steeply-sloping<br />

valleys, undulating terrain, gorges,<br />

tall limestone cliffs, coastal embayments<br />

and coastal sand dunes.<br />

The region surrounding Port Campbell<br />

and Peterborough supports 14 ecological<br />

vegetation classes (EVCs) but is<br />

dominated by cleared land and its predominantly<br />

introduced vegetation. Many<br />

of these EVCs exist as linear native vegetation<br />

remnants on public land along<br />

roadsides and watercourses that vary in<br />

condition from good to poor. Campbells<br />

Creek is the only watercourse traversed<br />

by the onshore pipeline.<br />

The onshore section of the proposed<br />

pipeline is located in the southern part of<br />

the Corangamite Shire. Towns within the<br />

shire have experienced varying changes,<br />

i.e, decline or growth, in population over<br />

the past two census periods.<br />

Land use in the onshore project area is<br />

primarily farmland, of high agricultural<br />

quality, which is used predominantly for<br />

grazing dairy cattle. The non-farmland<br />

areas (excluding remnant vegetation) are<br />

those covered by the Port Campbell National<br />

Park, which comprises unique<br />

coastal features (e.g., the Twelve Apostles<br />

rock formations) and is the focus for<br />

the region’s significant tourism industry.<br />

The Otway region is considered prospective<br />

for gas reserves and is increasingly<br />

becoming a secondary hub of gas supply<br />

to Victoria and interstate. Consequently,<br />

there are a number of existing<br />

and proposed gas production and<br />

processing infrastructure projects within<br />

the Casino Gas Field Development<br />

project area.<br />

Issues<br />

The significant environmental and social<br />

issues associated with the proposed Casino<br />

Gas Field Development are:<br />

• Drilling activities and discharges associated<br />

with the project may affect<br />

sea water quality and aquatic habitats.<br />

• Construction of subsea wellheads<br />

and offshore pipeline installation will<br />

disturb the sea bed.<br />

• Offshore construction activities will<br />

require temporary 500-m radius exclusion<br />

zones and during operations<br />

500-m radius exclusion zones will be<br />

in-place around the wellhead. These<br />

access constraints may affect commercial<br />

fisheries.<br />

• Noise generated by the drilling rig,<br />

pipelay vessels and support craft (including<br />

helicopters) may impact on<br />

marine mammals.<br />

viii<br />

Casino Gas Field Development

Executive Summary<br />

• Construction of the shore crossing<br />

site and installation of the onshore<br />

pipeline will unavoidably require vegetation<br />

clearing and land disturbance<br />

that may result in erosion and downstream<br />

sedimentation. Consequent<br />

issues include impacts on biodiversity<br />

and conservation resources, surface<br />

water quality and flow<br />

characteristics, land use and amenity,<br />

and Aboriginal and historical heritage<br />

sites.<br />

• The development will have the potential<br />

to impact on visual amenity if<br />

inappropriately designed and implemented.<br />

• Construction of the onshore components<br />

of the project will generate dust<br />

and noise. The consequent issues<br />

focus primarily on potential effects<br />

on local air quality (including greenhouse<br />

gas emissions), public amenity<br />

and safety.<br />

• Existing roads that will provide access<br />

to the project are used by multiple<br />

users including the local<br />

community, school buses and tourists.<br />

The proposed project will temporarily<br />

increase traffic on these<br />

roads. The consequent issues focus<br />

on traffic delays, amenity and public<br />

safety.<br />

• The proposed Casino Gas Field Development<br />

will create jobs which will<br />

result in a temporary increase in the<br />

local population. There are a range<br />

of positive and negative consequent<br />

issues that concern increasing pressure<br />

on community facilities, services<br />

and infrastructure, increasing<br />

social tensions and increasing expenditure<br />

locally.<br />

4. Impact Assessment<br />

A number of specialist studies were undertaken<br />

as part of the approval process<br />

to examine the existing environmental<br />

and social condition and determine the<br />

potential impacts of the Casino Gas Field<br />

Development. The key findings are summarised<br />

below.<br />

Bathymetry and Oceanography<br />

The Casino gas field is located on the<br />

continental shelf within Bass Strait. Factors<br />

influencing current flow through Bass<br />

Strait are tidal forcing, waves, winds and<br />

large-scale ocean circulation. The maximum<br />

water depth is 70 m at the proposed<br />

well sites and the seabed includes<br />

shallow valley and ‘spur’ features. The<br />

presence of the pipeline and associated<br />

equipment on the seabed is expected to<br />

have only a very localised effect on bottom<br />

currents that may lead to the localised,<br />

but negligible, redistribution of sea<br />

floor sediment.<br />

Marine Ecology<br />

Four marine habitats are expected to<br />

occur between the well sites and the<br />

shore and include intertidal, shallow, middepth<br />

and deep environments. Within<br />

these habitats there are 17 threatened<br />

marine bird species (most of which are<br />

migratory), 3 threatened whale species<br />

(blue whale, southern right whale and<br />

humpback whale) and a number of fish<br />

listed species (e.g., pipefishes,<br />

seahorses and seadragons) that may<br />

occur.<br />

The offshore pipeline traverses mainly<br />

sandy seabed and occassional patchy<br />

sponge gardens of varying density cover,<br />

and avoids significant raised relief reef<br />

habitat.<br />

Mitigation of effects on the marine environment<br />

is largely achieved by appropriate<br />

offshore pipeline route selection.<br />

Other mitigation and management measures<br />

in relation to drilling and well completion,<br />

pipeline construction and HDD<br />

shore crossing will be implemented such<br />

that biological, e.g., increased concentrations<br />

of heavy metals, and physical,<br />

e.g., turbid plumes and smothering, effects<br />

are expected to be minor, localised<br />

and temporary.<br />

Noise derived from offshore drilling and<br />

construction activities has the potential<br />

to impact on marine animals. The principal<br />

sources of ambient ocean noise in<br />

the project area are from air-ocean interaction<br />

and other oceanic processes,<br />

naturally occurring and biogenic background<br />

noise and noise from shipping<br />

activities. The reaction of marine animals<br />

to project-generated noise from drilling<br />

rigs and ships, supply vessels and<br />

helicopters will vary between species and<br />

individuals, but is predicted to range from<br />

localised avoidance to no reaction at all.<br />

Marine Commercial Fisheries<br />

The region supports a number of commercial<br />

fisheries. Localised and temporary<br />

disturbance may occur to target<br />

species from turbidity associated with<br />

construction activities. Safety exclusion<br />

zones (500-m radius) around the wells<br />

and pipelay vessel during construction,<br />

and around the wells during operations,<br />

will reduce the available fishing area,<br />

however this will not significantly impact<br />

the total fishing grounds available as the<br />

wells and pipeline do not impact on key<br />

fishing grounds. Various measures will<br />

be implemented to minimise the risk for<br />

trawling gear to interfere with the pipeline.<br />

Landform and Soils<br />

The Port Campbell National Park contains<br />

many sites of geological and<br />

geomorphological interest. Two Mile Bay<br />

(the site of the shore crossing) is rated<br />

as being of regional, and possibly state,<br />

significance. Measures will be implemented<br />

to minimise erosion and sedimentation,<br />

slope instability, soil inversion,<br />

compaction and subsidence along the<br />

pipeline alignment. Appropriate pipeline<br />

route selection, implementation of these<br />

measures and HDD of the shore crossing<br />

will provide long-term protection of<br />

the geological and geomorphological<br />

sites.<br />

Hydrology and Hydrogeology<br />

The ephemeral Campbells Creek is the<br />

only watercourse crossing along the onshore<br />

pipeline alignment, and it is classified<br />

as a regional drain and used for<br />

domestic, stock and irrigation purposes.<br />

The onshore pipeline will be placed below<br />

ground and where the pipeline<br />

crosses Campbells Creek below the bed<br />

of the waterway. Open trenching will be<br />

used to cross Campbells Creek and instream<br />

activity is not expected to take<br />

more than one day. Pipeline installation<br />

will be timed to occur during nil to low<br />

flow thereby minimising impacts to the<br />

hydrological regime of the creek. Erosion<br />

and sediment control measures will<br />

be put in place to control transport of<br />

sediment from construction areas and<br />

potentially impacting surface water quality.<br />

Two main aquifers occur in the project<br />

area: Port Campbell Limestone Aquifer<br />

and Dilwyn Formation Aquifer. No effects<br />

on groundwater are likely.<br />

Terrestrial Ecology<br />

The extent of remnant native vegetation<br />

within the project area is limited to the<br />

Port Campbell National Park, fragments<br />

within road corridors and scattered<br />

patches on private land. The remaining<br />

areas have been substantially modified<br />

through clearing of vegetation for agricultural<br />

land use. The majority of fauna<br />

species known to occur in the area were<br />

recorded from the Port Campbell National<br />

Park.<br />

Casino Gas Field Development<br />

ix

Executive Summary<br />

9<br />

8<br />

N<br />

Casino offshore pipeline route<br />

alignment<br />

Proposed gas wellhead location<br />

ROV footage location<br />

8<br />

7<br />

4 5 6<br />

Habitat description<br />

Subcropping/outcropping low relief<br />

hummocky calcisiltite/calcarenite<br />

interspersed with a patchy veneer of shelly<br />

calcareous course sand/fine gravel<br />

Fine to medium sand<br />

Fine to coarse gravel with patches of<br />

subcropping cemented sediments<br />

Course sand/fine gravel<br />

3<br />

Casino 4<br />

2<br />

Water<br />

depth<br />

(m)<br />

0<br />

10<br />

40<br />

50<br />

60<br />

70<br />

1<br />

Casino 5<br />

x<br />

Casino Gas Field Development

Executive Summary<br />

ROV location 3<br />

Sponges, hydrozoans, bryozoans and algae. Several demersal<br />

fish species<br />

ROV location 6<br />

Little or no epifaunal communities. Biological component<br />

principally infaunal and pelagic<br />

ROV location 9<br />

Little or no epifaunal communities. Biological component<br />

principally infaunal and pelagic<br />

ROV location 2<br />

Sponges, hydrozoans, bryozoans and algae. Several demersal<br />

fish species<br />

ROV location 5<br />

Sponges, hydrozoans, bryozoans and algae. Several demersal<br />

fish species<br />

ROV location 8<br />

Little or no epifaunal communities. Biological component<br />

principally infaunal and pelagic<br />

Figure 3 Seabed habitat classification of the Casino pipeline route<br />

ROV location 1<br />

Sponges, hydrozoans, bryozoans and algae. Several demersal<br />

fish species<br />

ROV location 4<br />

Little or no epifaunal communities. Biological component<br />

principally infaunal and pelagic<br />

ROV location 7<br />

Little or no epifaunal communities. Biological component<br />

principally infaunal and pelagic<br />

Casino Gas Field Development<br />

xi

Executive Summary<br />

668 000 670 000 672 000 674 000 676 000 678 000<br />

North–South Road<br />

Timboon–Peterborough Road<br />

Creek<br />

Camerons<br />

Hill Road<br />

North Paaratte<br />

Gas Plant<br />

Heytesbury<br />

Gas Plant<br />

Boundary Road<br />

Cheynes South Road<br />

Photo 5<br />

Photo 7<br />

Photo 6 Photo 8<br />

Proposed<br />

Otway Gas<br />

Project Plant<br />

Tregea Road<br />

Creek<br />

Waarre Road<br />

Wallaby<br />

TXU<br />

WUGS<br />

Facility<br />

Eastern Creek<br />

Road<br />

Smokey Point Road<br />

Road<br />

Curdie Vale–Port Campbell Road<br />

EasternCreekRoad<br />

Campbell Road<br />

Campbells Creek<br />

Langleys<br />

Brumbys Road<br />

Minerva<br />

Gas Plant<br />

Pascoe<br />

Photo 3<br />

Photo 4<br />

Photo 9<br />

Cobden–Port<br />

Rounds Road<br />

Currells Road<br />

HDD<br />

shore<br />

crossing<br />

site<br />

N<br />

0 km 1<br />

Map projection: AMG, ADG 66 Zone 54<br />

Sharps Road<br />

Photo 2<br />

Photo 1<br />

Port Campbell<br />

Casino pipeline route alignment<br />

HDD section<br />

Existing gas pipeline<br />

Proposed Otway Gas pipeline<br />

Road<br />

Creek<br />

Great Ocean Road<br />

Spring<br />

Jarvis Road<br />

5 724 000 5 726 000 5 728 000 5 730 000<br />

xii<br />

Casino Gas Field Development

Executive Summary<br />

Photo 2<br />

Proposed location of the HDD site, located in background in<br />

pasture behind dense roadside vegetation on the northern<br />

side of the Great Ocean Road<br />

Photo 6<br />

Site of the proposed Campbells Creek open trench crossing,<br />

adjacent to the recently constructed SEAgas pipeline<br />

Photo 9<br />

The TXU WUGS facility at Iona. Tie-in point for the Casino<br />

pipeline<br />

Photo 4<br />

View south of the Smokey Point Road proposed crossing<br />

location<br />

Photo 5<br />

View south of the Cheynes South Road proposed crossing<br />

location<br />

Photo 8<br />

Proposed site of the Cobden - Port Campbell Road HDD<br />

crossing<br />

Figure 4 Casino Gas Field Development onshore pipeline route travelogue<br />

Photo 1<br />

Two Mile Bay and Port Campbell National Park.<br />

HDD shore crossing will drill under this location.<br />

Photo 3<br />

East side of the Curdie Vale–Port Campbell Road proposed<br />

HDD road crossing<br />

Photo 7<br />

Campbells Creek Valley, showing the recently constructed<br />

and restored SEAgas pipeline easement<br />

Casino Gas Field Development<br />

xiii

Executive Summary<br />

Alignment of the proposed pipeline to<br />

avoid significant stands of native vegetation<br />

(habitat areas) is the most important<br />

mitigation measure employed for<br />

minimising impacts to terrestrial flora and<br />

fauna.<br />

Vegetation loss and fragmentation, and<br />

consequent fauna habitat and species<br />

loss, will also be minimised by the HDD<br />

shore crossing which will drill under and<br />

not disturb coastal vegetation in the Port<br />

Campbell National Park. A temporary 6-<br />

m wide access track will be required to<br />

the HDD site through native vegetation<br />

in the Great Ocean Road verge. The<br />

location of the access track will be selected<br />

based on a detailed botanical assessment<br />

during spring and the track<br />

will be fully revegetated following construction<br />

with local indigenous species.<br />

Permanent access to the MLV site during<br />

the operations phase will be via an<br />

existing track, which will require clearing<br />

of regrowth.<br />

Pipeline construction will require the removal<br />

of a limited number of trees (2 to<br />

3) and shrubs, at two road crossings<br />

(Smokey Point Road and Cheynes Road<br />

South), however vegetation at these locations<br />

is significantly degraded. Mitigation<br />

and management measures, such<br />

as narrowing the right-of-way from 24 m<br />

down to 5 m at these roadsides, will<br />

minimise impacts to native vegetation.<br />

Similarly, the Curdie Vale to Port<br />

Campbell Road will be drilled to avoid<br />

impacting significant roadside native vegetation.<br />

Consequentially, the onshore pipeline is<br />

not expected to impact significantly on<br />

terrestrial flora and fauna.<br />

Aboriginal and Historical Heritage<br />

Two broad zones of archaeological sensitivity<br />

were identified during the field<br />

survey: a moderate sensitivity zone located<br />

on the margin and valley slopes of<br />

Campbells Creek and a low to moderate<br />

sensitivity zone covering a wider area<br />

impacted by land clearing and pastoral<br />

land use activities.<br />

It is expected that the implementation of<br />

suitable management measures such as<br />

further pre-construction surveys and engagement<br />

of Aboriginal community representatives<br />

to monitor vegetation<br />

clearing and initial earthworks activities<br />

(within the framework of a heritage management<br />

agreement), will prevent adverse<br />

impacts occurring.<br />

No zones of historic archaeological sensitivity<br />

have been identified therefore impacts<br />

to known historic heritage sites<br />

are unlikely to occur. The offshore pipeline<br />

route avoids all known shipwrecks<br />

by several kilometres, the nearest being<br />

the Napier, 3 km away from the pipeline<br />

alignment.<br />

The greatest potential for impact relates<br />

to disturbing previously unrecorded heritage<br />

sites. Mitigation and management<br />

measures will include training project personnel<br />

in the identification of potential<br />

artefacts and developing protocols to<br />

manage heritage material identified during<br />

construction.<br />

Land Use and Infrastructure<br />

The pipeline traverses land that is used<br />

for agriculture. With the exception of the<br />

MLV site and marker signs, there will be<br />

no above ground infrastructure and all<br />

land will be reinstated to its previous<br />

land use. Therefore, only some shortterm<br />

impacts to agricultural land use are<br />

expected to arise during construction and<br />

installation of the pipeline from the HDD<br />

shore crossing location to the TXU<br />

WUGS facility.<br />

Potential impacts to infrastructure have<br />

been mitigated to the greatest extent<br />

practicable by aligning the pipeline to<br />

accommodate landholder and asset<br />

owner requirements. Residual impacts<br />

will be managed through ongoing consultation<br />

with landholders and asset owners<br />

to address property specific issues<br />

and agree measures to mitigate or compensate<br />

any potential disruption or<br />

losses. Consequently, long-term detrimental<br />

impacts are not likely to result.<br />

Socio-economics<br />

Construction of the onshore components<br />

of the Casino Gas Field Development<br />

will require a small workforce of up to 45<br />

personnel resulting in a short-term increase<br />

in the local population. Given the<br />

small size of the onshore construction<br />

workforce, it is not expected to place<br />

significant pressure on community infrastructure,<br />

accommodation facilities and<br />

services such as medical facilities. It is<br />

possible that a construction camp will be<br />

established to avoid impacting on local<br />

facilities as construction will coincide with<br />

the summer tourist period. The offshore<br />

construction workforce of about 250 personnel<br />

will be accommodated on the drilling<br />

rig and pipelay vessel.<br />

Development of the Casino gas field is<br />

expected to generate employment opportunities<br />

and a requirement for support<br />

services. Although some positions<br />

will require specialist skills, there will be<br />

a requirement for positions to be filled<br />

locally and for the provision of local goods<br />

and services. This will have a positive<br />

economic impact through increased local<br />

expenditure.<br />

Visual Amenity<br />

Impacts to visual amenity during construction<br />

will be temporary, and are<br />

largely able to be avoided through the<br />

application of appropriate planning, design<br />

and construction strategies. Longerterm<br />

impacts have been mitigated by<br />

electing to install subsea wellheads, constructing<br />

the shore crossing by HDD from<br />

farmland and by screening the MLV site<br />

behind remnant native vegetation at the<br />

Great Ocean Road. Visual impacts of<br />

the onshore pipeline corridor will be limited<br />

to the construction phase after which<br />

the easement will be rehabilitated.<br />

Consequently, significant long-term impacts<br />

to the visual amenity of the region<br />

are unlikely to result from construction<br />

and operation of the Casino Gas Field<br />

Development.<br />

Noise<br />

Onshore noise emissions are associated<br />

with pipeline construction activities and<br />

HDD of the shore crossing and will be<br />

mitigated by locating the pipeline and<br />

shore crossing at a sufficient distance<br />

from sensitive receptors. The HDD operation<br />

will potentially result in noise nuisance<br />

at the nearest residence (300 m<br />

from the HDD site) and so further mitigation<br />

measures are being considered in<br />

consultation with the relevant landholder<br />

to achieve EPA requirements. No significant<br />

noise emissions are expected during<br />

normal pipeline operations.<br />

Air Quality<br />

The composition of the Casino gas is<br />

such that additional emissions from its<br />

processing at the TXU WUGS facility will<br />

not occur.<br />

The project has the potential to generate<br />

dust (resulting from soil disturbance) or<br />

exhaust emissions (associated with vehicles<br />

and heavy machinery). Mitigation<br />

and management measures will be implemented<br />

to manage these emissions.<br />

Given the short period of onshore pipeline<br />

construction and the application of<br />

xiv<br />

Casino Gas Field Development

Executive Summary<br />

appropriate mitigation and management<br />

measures, impacts to air quality are unlikely<br />

to occur as a result of the construction<br />

or operation of the Casino Gas Field<br />

Development.<br />

Greenhouse Gas<br />

Greenhouse gas emissions will vary over<br />

the life of the Casino Gas Field Development.<br />

The project will generate minor<br />

greenhouse gas emissions during the<br />

construction and installation stages, primarily<br />

from vehicle exhaust emissions,<br />

however, these emissions are short-term<br />

and not significant contributors to Victoria’s<br />

or Australia’s total emissions. Emissions<br />

during operation of the pipeline will<br />

be minimal comprising potential fugitive<br />

emissions and minor quantities of vehicle<br />

emissions. As a signatory to the<br />

APPEA Greenhouse Challenge, <strong>Santos</strong><br />

will continue to address reduction management<br />

of greenhouse gas emissions.<br />

Traffic<br />

The roads within the project area are<br />

multi-user roads. The potential impacts<br />

associated with construction traffic include<br />

road safety and potential interruption<br />

to traffic movements. A construction<br />

traffic management plan will be developed<br />

in consultation with relevant regulatory<br />

authorities and implemented as<br />

appropriate. It is expected that impacts<br />

resulting from construction traffic can be<br />

mitigated with the implementation of this<br />

plan.<br />

Condensate will be transported from the<br />

TXU WUGS facility to a refinery by single<br />

road tankers, resulting in 2 to 3 trucks<br />

per week. The volume of condensate<br />

and therefore trucks is expected to decline<br />

to about one per week after the first<br />

two years of field production. Based on<br />

this low and declining volume of condensate<br />

transport road traffic, and the application<br />

of the existing road safety<br />

management requirements for current<br />

traffic from the TXU WUGS facility, this<br />

minor increase in volume is not expected<br />

to significantly impact local traffic conditions.<br />

Hazard and Risk<br />

The Pipelines Act 1967 requires that a<br />

detailed risk assessment be undertaken<br />

in accordance with the requirements of<br />

the Australian standard for high-pressure<br />

gas pipelines, AS2885.1. Consequently,<br />

the Casino Gas Field Development is<br />

designed and operated to achieve hazard<br />

and risk levels that are as low as<br />

reasonably possible. Prior to the granting<br />

of the Pipeline Licence <strong>Santos</strong> will<br />

undertake such a risk assessment the<br />

results of which will be incorporated into<br />

final project planning and design as required.<br />

5. <strong>Environment</strong>al<br />

Management<br />

<strong>Santos</strong> has developed an environment,<br />

health and safety management system<br />

(EHSMS) which consists of two sets of<br />

standards: management standards and<br />

hazard standards. A project-specific environment<br />

plan (EP), for offshore components,<br />

and environmental<br />

management plan (EMP), for onshore<br />

components, will be prepared for the<br />

Casino Gas Field Development within<br />

the framework of the EHSMS.<br />

Pipeline alignment is the most effective<br />

mitigation measure for minimising impacts.<br />

Residual impacts are then mitigated<br />

and managed through the<br />

implementation of appropriate measures<br />

and procedures. Table 1 summarises the<br />

impacts associated with the project, together<br />

with the mitigation and management<br />

measures, additional to pipeline<br />

alignment that will form the basis of the<br />

EP and EMP.<br />

Casino Gas Field Development<br />

xv

Executive Summary<br />

Table 1<br />

<strong>Environment</strong>al mitigation and management measures<br />

Element Potential Issue/Impact Proposed Mitigation and Management Measure<br />

Bathymetry and<br />

oceanography<br />

Marine ecology<br />

Commercial<br />

fisheries<br />

Landform and<br />

Soils<br />

Pipeline stability on the seabed<br />

Spanning of pipeline<br />

Effect on sea water quality and<br />

aquatic habitats<br />

Impacts of project-generated<br />

noise on marine animals<br />

Effects on fishery operations<br />

Wind and water erosion<br />

Pipeline will be weighted (concrete coating or thicker wall steel pipe) to provide onbottom<br />

stability<br />

Pipeline route was selected to avoid significant spans<br />

Grout-filled bladders will fill minor spans to support pipeline<br />

Pipeline will be surveyed and retrospective maintenance as necessary to address<br />

pipeline spanning<br />

Offshore pipeline is aligned to avoid key reef habitats and predominantly traverse<br />

sandy seabed<br />

HDD will be employed for the shore crossing to avoid impacts to nearshore reef and<br />

coastal habitat<br />

Oil spill contingency response plan implemented for exploration drilling will be<br />

expanded to include all field development and operation activities<br />

Strict vessel refuelling procedures will be employed to prevent spillage at sea<br />

A waste management strategy will be developed for all marine activities based on<br />

Australian and international standards<br />

Vessels will comply with standard requirements for the prevention of the introduction<br />

of pests<br />

Low toxicity, water-based drilling fluid additives will be used<br />

HDD fluid discharge to the marine environment will be minimised<br />

Hydrostatic test water will be low-toxicity and discharged from the Casino 5 wellhead<br />

over a four-day period to ensure further dilution and dispersion<br />

Protocols will be developed in accordance with EPBC regulations to minimise<br />

interaction with whales during construction and drilling<br />

Construction will minimise or avoid the types of vessel and aircraft movements that<br />

are known to elicit disturbance reactions<br />

Aerial observations will be undertaken to monitor whale activity during the period<br />

leading up to and during the drilling program, where it coincides with whale migration<br />

or presence<br />

Helicopters will be flown at a minimum altitude of 1,000 m over ocean<br />

Watch will be maintained for whales in the vicinity of vessel activities during<br />

pipelaying such that responses including reduction of speed, minimisation of sonar<br />

use, and instructions to helicopter pilots/ancillary vessels to avoid whales can be<br />

implemented<br />

Offshore pipeline is aligned to avoid key fishing areas<br />

HDD will be employed for the shore crossing to avoid impacts to nearshore lobster<br />

and abalone habitat<br />

500-m radius exclusions zones will be implemented during construction (well sites<br />

and pipelay vessel) and operation (wellheads only) to minimise collision risk and<br />

gear loss<br />

Digital information on position of wellheads and subsea pipeline will be provided to<br />

commercial fishers<br />

Location, timing and duration of construction activities will be communicated with<br />

commercial fishers<br />

A gear retrieval or replacement policy will be implemented where it becomes<br />

snagged on project infrastructure<br />

Construction is scheduled for the drier months of the year and activity will be limited<br />

during heavy rain<br />

Maximum coverage of vegetation will be retained and rehabilitated expeditiously<br />

A special crossing crew will construct the Campbells Creek crossing and will retain a<br />

vegetation buffer on the banks and approach slopes, reinstate immediately following<br />

pipelay using appropriate stabilisation measures and undertake additional<br />

revegetation to enhance the riparian corridor<br />

Erosion and sediment control measures will be installed and maintained during<br />

construction and operations<br />

The pipeline easement will be monitored for erosion, sedimentation and stability<br />

xvi<br />

Casino Gas Field Development

Executive Summary<br />

Table 1<br />

<strong>Environment</strong>al mitigation and management measures (cont’d)<br />

Element Potential Issue/Impact Proposed Mitigation and Management Measure<br />

Landform and<br />

Soils (cont’d)<br />

Hydrology and<br />

hydrogeology<br />

Terrestrial<br />

ecology<br />

Slope instability<br />

Soil inversion, compaction and<br />

subsidence<br />

Soil contamination<br />

Disturbance to significant<br />

features<br />

Water quality<br />

Disruption to water flow regimes<br />

Clearing of remnant native<br />

vegetation and loss of significant<br />

flora and fauna with consequent<br />

biodiversity and conservation<br />

impacts<br />

Onshore pipeline alignment was selected to avoid areas of significant slope<br />

instability and slumping<br />

Topsoil will be stripped and stockpiled separately to trench spoil<br />

Soils will be reinstated in the reverse order of excavation to avoid inversion of soil<br />

profiles<br />

Construction ROW access during or immediately after heavy rain will be limited<br />

Trench backfill will be compacted and if necessary a raised crown will be installed<br />

(less than 20 cm) over the trench to mitigate subsidence<br />

Soils will be scarified to relieve compaction, where necessary<br />

Temporary and permanent storage of fuels, lube oils and other hazardous chemicals<br />

will be within areas or facilities designed to contain spills<br />

Appropriate hazardous chemical handling procedures will be implemented<br />

Appropriate measures to prevent third party rupture of the MEG pipeline will be<br />

implemented including pipeline marker signs, in-trench marker tape and appropriate<br />

depth of burial<br />

A spill contingency response plan will be developed and implemented<br />

HDD will be employed for the shore crossing to avoid surface impacts to coastal<br />

landforms<br />

Construction is scheduled for the driest months of the year<br />

The Campbells Creek crossing will be constructed during period of nil to low flow,<br />

where practicable or employ stream flow diversion measures (flume or dam and<br />

pump) to minimise sediment release<br />

The pipeline will be buried at a greater depth at the Campbells Creek crossing to<br />

minimise risk of scour<br />

Stockpiles will be placed more than 10 m from the top-of-bank at Campbells Creek<br />

Temporary and permanent storage of fuels, lubes and other hazardous chemicals<br />

will be within areas or facilities designed to contain spills<br />

Appropriate hazardous chemical handling procedures will be implemented (e.g., no<br />

refuelling of machinery and equipment within 20 m of Campbells Creek)<br />

A spill contingency response plan will be developed and implemented<br />

A raised crown will be installed over the trench to compensate for subsidence and<br />

crown breaks created every 30 m to prevent impedance of surface flows<br />

The Campbells Creek crossing will be constructed during nil to low flow, where<br />

practicable or stream flow diversion measures employed (flume or dam and pump) to<br />

maintain flow<br />

Positive HDD fluid pressure will be maintained during drilling and the drill hole cased<br />

to prevent preferential flow of groundwater along the drill hole<br />

HDD shore crossing will drill under the surface of Port Campbell National Park and<br />

Great Ocean Road avoiding native vegetation clearance<br />

Temporary access to the HDD site will be selected based on a targeted search for<br />

rare or endangered species to avoid any that may be present, where practicable.<br />

The access will be revegetated with local native species following construction to<br />

reflect the existing ecological vegetation class (EVC)<br />

The pipeline route is aligned through open farmland and traverses native vegetation<br />

at two minor road crossings only where it is aligned through degraded native<br />

vegetation. The ROW will be narrowed from 24-m down to 5-m at these road<br />

crossings<br />

Impacts to native vegetation within the Port Campbell National Park to enable<br />

temporary surface placement of the HDD sensing cable will be kept to an absolute<br />

minimum, involve hand trimming only, include restoration of any disturbed areas and<br />

be undertaken in consultation with Parks Victoria.<br />

Casino Gas Field Development<br />

xvii

Executive Summary<br />

Table 1<br />

<strong>Environment</strong>al mitigation and management measures (cont’d)<br />

Element Potential Issue/Impact Proposed Mitigation and Management Measure<br />

Terrestrial<br />

ecology (cont’d)<br />

Aboriginal and<br />

historic heritage<br />

Land use and<br />

infrastructure<br />

Socio-economic<br />

Visual amenity<br />

Potential for disturbance to<br />

Aboriginal and historic heritage<br />

sites<br />

Construction and operation of<br />

the pipeline may effect current<br />

land use activities<br />

Interference with the operation<br />

of existing infrastructure<br />

Creation of jobs and requirement<br />

for supporting goods and<br />

services<br />

Short-term additional demand<br />

for services, facilities and<br />

infrastructure, potential to create<br />

social tensions<br />

Alteration to the visual<br />

landscape associated with<br />

vegetation clearing and the<br />

introduction of project<br />

infrastructure<br />

Campbells Creek crossing is aligned to avoid clearance of significant riparian<br />

vegetation<br />

Cleared native vegetation will be retained on site and respread over the easement<br />

during rehabilitation<br />

The period and length of time the trench remains open will be minimised and the<br />

open trench will be monitored for fauna<br />

Weed and pathogen hygiene measures will be implemented for the project,<br />

particularly in relation to access to the Port Campbell National Park<br />

Any areas of native vegetation impacted by the project shall be revegetated with<br />

indigenous species to reflect the original EVC in line with the principles of net gain<br />

Disturbed areas will be revegetated as soon as practicable following construction<br />

Permanent access to the MLV site will be via an existing narrow track, which will<br />

require minor clearing of native regrowth and weed species.<br />

An Aboriginal heritage management plan will be implemented in consultation with the<br />

relevant Aboriginal communities<br />

Additional sub-surface Aboriginal heritage surveys will be undertaken in the<br />

Campbells Creek valley prior to construction in consultation with the relevant<br />

Aboriginal communities<br />

Representatives from the relevant Aboriginal communities will be engaged to monitor<br />

clearing and initial earthworks for previously undetected heritage artefacts<br />

Appropriate site management will be implemented in consultation with relevant<br />

Aboriginal heritage communities and regulatory authorities<br />

A protocol for the management of any new potential Aboriginal or historic heritage<br />

sites uncovered during construction will be implemented within the heritage<br />

management plan framework<br />

The pipeline has been aligned through properties in consultation with landholders to<br />

minimise impacts to farm operations (e.g., follow existing easements and fence<br />

lines), where practicable<br />

A weed and pathogen management plan will be implemented, including appropriate<br />

hygiene measures to prevent the introduction and spread of weeds and pathogens<br />

Liaison with landholders will be undertaken to determine the most appropriate<br />

measures to minimise impacts to farm operations<br />

The easement and farm infrastructure will be reinstated in a manner that minimises<br />

disruption and losses to landholders<br />

<strong>Santos</strong> will continue to liaise with Woodside Energy Ltd with regard to minimising<br />

impacts where pipeline construction for the Casino Gas Field Development and the<br />

Otway Gas Project is within the same property<br />

Crossing of the Curdie Vale to Port Campbell Road and Cobden to Port Campbell<br />

Road will be by HDD<br />

Utility infrastructure asset owners will be consulted regarding potential impacts to<br />

utilities associated with pipeline route selection, construction and operation activities<br />

Where possible, employees and goods and services will be sourced locally<br />

The field interaction protocol will continue to be implemented to guide personnel on<br />

appropriate standards of conduct during field activities<br />

<strong>Santos</strong> and the construction contractor will consult with local authorities and service<br />

providers regarding resourcing issues<br />

Installation of subsea wellheads will avoid offshore visual impacts<br />

Well locations will be identified on marine charts and coordinates provided to<br />

commercial fishers to negate the need for marker buoys to mark well locations<br />

The shore crossing will be constructed by HDD<br />

xviii<br />

Casino Gas Field Development

Executive Summary<br />

Table 1<br />

<strong>Environment</strong>al mitigation and management measures (cont’d)<br />

Element Potential Issue/Impact Proposed Mitigation and Management Measure<br />

Visual amenity<br />

(cont’d)<br />

Noise<br />

Air quality<br />

Potential noise nuisance to<br />

adjacent residents during<br />

construction and operation<br />

Generation of dust and exhaust<br />

emissions<br />

The pipeline alignment selected minimises vegetation clearance<br />

The onshore pipeline will be buried<br />

The HDD and MLV site will be screened behind dense roadside vegetation at the<br />

Great Ocean Road<br />

The location of the construction camp, if required, will be in an area of previous<br />

disturbance and established and operated in a manner that minimises visual<br />

intrusion<br />

Noisy activities will be scheduled for during the day to coincide with higher ambient<br />

noise, where practicable<br />

Measures will be undertaken to attenuate noise from the HDD, if necessary, e.g.,<br />

noise barriers, or alternatively arrangements will be implemented with the affected<br />

residents to avoid noise nuisance<br />

Potentially affected residents will be informed of the status of construction activities<br />

The extent of clearing and earthworks will be limited and the period surfaces are<br />

exposed minimised<br />

Vehicle speeds will be restricted on unsealed tracks and the pipeline easement<br />

Appropriate means to stabilise soils in dusty conditions will be used, e.g., water<br />

trucks<br />

Vehicles and plant will be appropriately maintained<br />

The pipeline and associated appurtenances will be appropriately maintained to<br />

minimise fugitive emissions during operations<br />

Planned venting operations, if undertaken, will be during appropriate weather<br />

conditions to facilitate rapid dispersion<br />

Greenhouse gas Emissions of greenhouse gases The pipeline and associated appurtenances will be appropriately maintained to<br />

minimise fugitive emissions during operations<br />

Traffic<br />

Hazard and Risk<br />

Alteration to existing traffic<br />

conditions, e.g., increased road<br />

use<br />

Risk of rupture of the gas or<br />

MEG pipelines, or impacts to<br />

wellhead facilities<br />

Bushfire resulting from<br />

construction activities<br />

Vehicles and other internal combustion equipment will be appropriately maintained<br />

Quantities of vented natural gas during commissioning and operations will be<br />

minimised<br />

A traffic management plan for the construction and operations phases will be<br />

developed and implemented in consultation with VicRoads and the Corangamite<br />

Shire<br />

The pipeline and associated appurtenances will be located to minimise risk of<br />

interference<br />

Design and construction of wellhead facilities, the pipeline and associated<br />

appurtenances will be in accordance with Australian standard AS2885 and<br />

consequently, the project risk assessment study<br />

Bushfire prevention and response procedures will be developed in consultation with<br />

relevant regulatory authorities for incorporation into the Safety Management Plan<br />

Casino Gas Field Development<br />

xix

Executive Summary<br />

xx<br />

Casino Gas Field Development

Contents<br />

Contents<br />

Executive Summary<br />

v<br />

1. Introduction 1<br />

1.1 Project Outline 1<br />

1.2 Project Proponent 1<br />

1.2.1 <strong>Santos</strong> Ltd 1<br />

1.2.2 Australian Worldwide Exploration Limited 3<br />

1.2.3 Mitsui & Co. (Australia) Ltd 3<br />

1.3 Project Justification 3<br />

1.4 About This Document 4<br />

1.5 EIA Study Team 4<br />

2. Regulatory Framework 5<br />

2.1 Approval Process Overview 5<br />

2.2 Planning and <strong>Environment</strong>al Approvals 5<br />

2.2.1 EPBC Act 1999 5<br />

2.2.2 <strong>Environment</strong> Effects Act 1978 6<br />

2.2.3 Planning and <strong>Environment</strong> Act 1987 7<br />

2.2.4 Coastal Management Act 1995 7<br />

2.2.5 Native Title 7<br />

2.2.6 Net Gain Policy 8<br />

2.3 Well Development Approvals 8<br />

2.3.1 Commonwealth Petroleum (Submerged Lands) Act 1967 8<br />

2.4 Pipeline Approvals 8<br />

2.4.1 Commonwealth Petroleum (Submerged Lands) Act 1967 8<br />

2.4.2 Victorian Petroleum (Submerged Lands) Act 1982 8<br />

2.4.3 Pipelines Act 1967 8<br />

2.4.4 Easement Acquisition 8<br />

2.5 Subsequent Approvals 9<br />

3. Stakeholder Consultation 11<br />

3.1 Relevant Stakeholders 11<br />

3.2 Stakeholder Consultation Program 11<br />

3.3 Consultation Records 13<br />

4. Project Rationale 15<br />

4.1 Australia’s Gas Industry 15<br />

4.2 Rationale for Development 15<br />

4.3 Benefits of the Proposal 15<br />

4.3.1 Supplementation of Existing Gas Reserves 15<br />

4.3.2 Security of Supply 15<br />

4.3.3 Increased Gas Supply Competition 16<br />

Casino Gas Field Development xxi

Contents<br />

4.3.4 Commercial Benefits 16<br />

4.3.5 Potential Greenhouse Benefits 16<br />

4.4 Project Alternatives 17<br />

4.4.1 The ‘Do Nothing’ Scenario 17<br />

4.4.2 Alternative Gas Supplies 17<br />

4.4.3 Alternative Energy Sources 17<br />

4.4.4 Alternative Development Scenarios 18<br />

5. Project Description 19<br />

5.1 Reservoir and Gas Specifications 20<br />

5.2 Project Design Specifications 20<br />

5.3 Pipeline Route Selection 20<br />

5.3.1 Shore Crossing 21<br />

5.3.2 Offshore Pipeline 21<br />

5.3.3 Onshore Pipeline 21<br />

5.4 Description of Construction Activities 25<br />

5.4.1 Drilling and Wellhead Installation 25<br />

5.4.2 Offshore Pipeline and Umbilical Installation 30<br />

5.4.3 Shore Crossing 30<br />

5.4.4 Onshore Pipeline 32<br />

5.4.5 Ancillary Facilities 42<br />

5.5 Commissioning 43<br />

5.6 Operations 43<br />

5.7 Decommissioning 43<br />

5.8 Project Life 44<br />

5.9 Project Development Schedule 44<br />

6. Impact Assessment 45<br />

6.1 Climate 45<br />

6.2 Bathymetry and Oceanography 45<br />

6.2.1 Sources of Information 45<br />

6.2.2 Existing <strong>Environment</strong> 45<br />

6.2.3 Potential Impacts 46<br />

6.2.4 Mitigation and Management Measures 46<br />

6.2.5 Residual Impacts 47<br />

6.3 Marine Ecology 47<br />

6.3.1 Survey Methodology 47<br />

6.3.2 Existing <strong>Environment</strong> 47<br />

6.3.3 Potential Impacts 51<br />

6.3.4 Impact Assessment 51<br />

6.3.5 Mitigation and Management Measures 54<br />

6.4 Marine Acoustics 54<br />

6.4.1 Existing <strong>Environment</strong> 54<br />

6.4.2 Construction Related Noise 56<br />

6.4.3 Potential Impacts to Whales 57<br />

6.4.4 Mitigation and Management Measures 60<br />

6.5 Marine Commercial Fisheries 61<br />

6.5.1 Existing <strong>Environment</strong> 61<br />

xxii<br />

Casino Gas Field Development

Contents<br />

6.5.2 Potential Impacts 63<br />

6.5.3 Mitigation and Management Measures and Residual Impacts 63<br />

6.6 Landform and Soils 64<br />

6.6.1 Existing <strong>Environment</strong> 64<br />

6.6.2 Potential Impacts 67<br />

6.6.3 Mitigation and Management Measures and Residual Impacts 67<br />

6.7 Hydrology and Hydrogeology 69<br />

6.7.1 Existing <strong>Environment</strong> 69<br />

6.7.2 Potential Impacts 69<br />

6.7.3 Mitigation and Management Measures and Residual Impacts 69<br />

6.8 Terrestrial Ecology 70<br />

6.8.1 Survey Methodology 70<br />

6.8.2 Existing <strong>Environment</strong> 71<br />

6.8.3 Potential Impacts 79<br />

6.8.4 Mitigation and Management Measures and Residual Impacts 79<br />

6.9 Aboriginal Heritage 84<br />

6.9.1 Survey Methodology 84<br />

6.9.2 Existing <strong>Environment</strong> 85<br />

6.9.3 Potential Impacts 87<br />

6.9.4 Mitigation and Management Measures 87<br />

6.9.5 Residual Impacts 88<br />

6.10 Historical Heritage 88<br />

6.10.1 Methodology 88<br />

6.10.2 Existing <strong>Environment</strong> 88<br />

6.10.3 Potential Impacts 88<br />

6.10.4 Mitigation and Management Measures and Residual Impacts 88<br />

6.10.5 Residual Impacts 89<br />

6.11 Land Use and Infrastructure 89<br />

6.11.1 Existing <strong>Environment</strong> 89<br />

6.11.2 Potential Impacts 92<br />

6.11.3 Impact Assessment, Mitigation and Management Measures 93<br />

6.11.4 Residual Impacts 95<br />

6.12 Socio-economic 96<br />

6.12.1 Existing <strong>Environment</strong> 96<br />

6.12.2 Impact Assessment 97<br />

6.12.3 Mitigation and Management Measures 98<br />

6.13 Visual Amenity 99<br />

6.13.1 Existing <strong>Environment</strong> 99<br />

6.13.2 Potential Impacts 100<br />

6.13.3 Impact Assessment 100<br />

6.13.4 Mitigation and Management Measures 102<br />

6.14 Noise 103<br />

6.14.1 Existing <strong>Environment</strong> 103<br />

6.14.2 Impact Assessment 103<br />

6.14.3 Mitigation and Management Measures 106<br />

6.15 Air Quality 106<br />

Casino Gas Field Development xxiii

Contents<br />

6.15.1 Existing <strong>Environment</strong> 106<br />

6.15.2 Potential Impacts 106<br />

6.15.3 Mitigation and Management Measures 107<br />

6.15.4 Residual Impacts 107<br />

6.16 Greenhouse Gas 107<br />

6.16.1 Background 107<br />

6.16.2 Sources of Greenhouse Gases 107<br />

6.16.3 Mitigation and Management Measures 107<br />

6.17 Traffic 108<br />

6.17.1 Existing <strong>Environment</strong> 108<br />

6.17.2 Potential Impacts 108<br />

6.17.3 Mitigation and Management Measures 108<br />

6.17.4 Residual Impacts 109<br />

6.18 Hazard and Risk 109<br />

7. <strong>Environment</strong>al Management Framework 111<br />

7.1 <strong>Environment</strong>, Health and Safety Management System 111<br />

7.1.1 Policy 112<br />

7.1.2 Plan 112<br />

7.1.3 Implement 113<br />

7.1.4 Monitor and Evaluate 116<br />

7.1.5 Review 116<br />

8. References 117<br />

9. Glossary 121<br />

Figures<br />

1.1 Casino Gas Field Development pipeline alignment 2<br />

1.2 Casino Gas Field Development schematic 3<br />

2.1 Casino Gas Field Development lead environmental approvals process flow chart 6<br />

4.1 Total natural gas consumption in Australia, 1979-2001 15<br />

4.2 Australia’s primary energy consumption by fuel type, 1980-81 and 2000-01 16<br />

4.3 Australia’s natural gas consumption by state, 2001 16<br />

4.4 Australia’s gas pipelines and gas fields 17<br />

5.1 Casino Gas Field Development schematic 19<br />

5.2 Casino Gas Field Development HDD shore crossing options 22<br />

5.3 Casino Gas Field Development onshore pipeline route sub-options 24<br />

5.4 Casino Gas Field Development onshore pipeline route 27<br />

5.5 Casino Gas Field Development onshore pipeline route travelogue 29<br />

5.6 Typical subsea wellhead configuration 30<br />

5.7 Offshore pipeline cross section (umbilical shown strapped to pipeline, but may be laid separately<br />

adjacent to pipeline) 32<br />

5.8 Typical offshore pipeline spanning stabilisation treatment 32<br />

5.9 HDD shore crossing - site location and construction site layout 33<br />

5.10 HDD shore crossing profile 34<br />

xxiv<br />

Casino Gas Field Development

Contents<br />

5.11 Typical mainline construction ROW cross section 35<br />

5.12 Onshore pipeline construction ROW 36<br />