Mine to Market November-December 2012 - Mount Isa Mines

Mine to Market November-December 2012 - Mount Isa Mines

Mine to Market November-December 2012 - Mount Isa Mines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

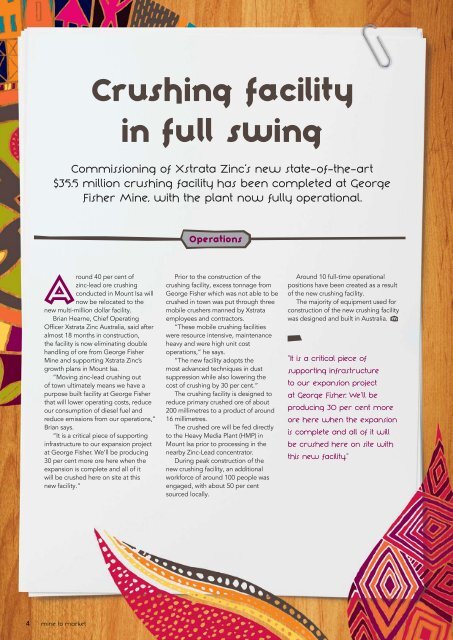

Crushing facility<br />

in full swing<br />

Commissioning of Xstrata Zinc’s new state-of-the-art<br />

$35.5 million crushing facility has been completed at George<br />

Fisher <strong>Mine</strong>, with the plant now fully operational.<br />

Around 40 per cent of<br />

zinc-lead ore crushing<br />

conducted in <strong>Mount</strong> <strong>Isa</strong> will<br />

now be relocated <strong>to</strong> the<br />

new multi-million dollar facility.<br />

Brian Hearne, Chief Operating<br />

Officer Xstrata Zinc Australia, said after<br />

almost 18 months in construction,<br />

the facility is now eliminating double<br />

handling of ore from George Fisher<br />

<strong>Mine</strong> and supporting Xstrata Zinc’s<br />

growth plans in <strong>Mount</strong> <strong>Isa</strong>.<br />

“Moving zinc-lead crushing out<br />

of <strong>to</strong>wn ultimately means we have a<br />

purpose built facility at George Fisher<br />

that will lower operating costs, reduce<br />

our consumption of diesel fuel and<br />

reduce emissions from our operations,”<br />

Brian says.<br />

“It is a critical piece of supporting<br />

infrastructure <strong>to</strong> our expansion project<br />

at George Fisher. We’ll be producing<br />

30 per cent more ore here when the<br />

expansion is complete and all of it<br />

will be crushed here on site at this<br />

new facility.”<br />

Prior <strong>to</strong> the construction of the<br />

crushing facility, excess <strong>to</strong>nnage from<br />

George Fisher which was not able <strong>to</strong> be<br />

crushed in <strong>to</strong>wn was put through three<br />

mobile crushers manned by Xstrata<br />

employees and contrac<strong>to</strong>rs.<br />

“These mobile crushing facilities<br />

were resource intensive, maintenance<br />

heavy and were high unit cost<br />

operations,” he says.<br />

“The new facility adopts the<br />

most advanced techniques in dust<br />

suppression while also lowering the<br />

cost of crushing by 30 per cent.”<br />

The crushing facility is designed <strong>to</strong><br />

reduce primary crushed ore of about<br />

200 millimetres <strong>to</strong> a product of around<br />

16 millimetres.<br />

The crushed ore will be fed directly<br />

<strong>to</strong> the Heavy Media Plant (HMP) in<br />

<strong>Mount</strong> <strong>Isa</strong> prior <strong>to</strong> processing in the<br />

nearby Zinc-Lead concentra<strong>to</strong>r.<br />

During peak construction of the<br />

new crushing facility, an additional<br />

workforce of around 100 people was<br />

engaged, with about 50 per cent<br />

sourced locally.<br />

Around 10 full-time operational<br />

positions have been created as a result<br />

of the new crushing facility.<br />

The majority of equipment used for<br />

construction of the new crushing facility<br />

was designed and built in Australia.<br />

“It is a critical piece of<br />

supporting infrastructure<br />

<strong>to</strong> our expansion project<br />

at George Fisher. We’ll be<br />

producing 30 per cent more<br />

ore here when the expansion<br />

is complete and all of it will<br />

be crushed here on site with<br />

this new facility.”<br />

4 mine <strong>to</strong> market