Shaping with a Router - MetosExpo - Free

Shaping with a Router - MetosExpo - Free

Shaping with a Router - MetosExpo - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Q & A (continued)<br />

use widl oily woods, but any of me standard brands should give<br />

good results for veneering, such as System lhree, West System,<br />

Suncure and Armstrong NB (check wim your local hardware store<br />

and building or boating supply for sources).<br />

However, epoxy is considerably less convenient to use man a<br />

contact adhesive. You'll need to devise a way to apply even<br />

clamping pressure and a defensive strategy for coping wim<br />

messy squeeze-out. It helps to apply dle epoxy dlinly and to<br />

have rubber gloves and lots of rags. Use denatured alcohol during<br />

cleanup, not acetone (which is extremely flat1Ul1able) or<br />

mematl01 (which has very toxic vapors mat pass right d1fough atl<br />

orgatlic-vapor respirator). As a reward, mough, you should get a<br />

glue bond mat lasts forever.<br />

[George Mustoe is a geochemistry research techniciatl at Western<br />

Washington University in Bellinghatn, Wash.]<br />

Identifying an old tenon maker<br />

Everyone loves a mystery, even woodworkers. Recently, I ran<br />

across an antique hand tool I can't identify. The tool is about<br />

lO in. tall <strong>with</strong> a square, tapered drive shank, obviously made<br />

to be chucked in a hand brace. The tool has an intricate camadjustment<br />

mechanism for increasing or decreasing the size<br />

of the opening on its bottom and a pencil-sharpener-like<br />

blade offset to the side, probably for the purpose of peeling off<br />

wood. The tool bears the trademark CN. Stearns and has a<br />

patent number stamped on it. Can anyone tell me what this<br />

tool was used for? -John A Macdonald, Los Osos, Cal.<br />

Richard Starr replies: It's a hollow auger, made for cutting a<br />

round tenon on dle end of a stick. They were used by wheelwrights,<br />

chairmakers, laddermakers and omer artiSatls who prefen-ed<br />

to cut tenons wim a tool mounted in a brace ramer man<br />

whinling mem out by hand or turning mem on a lame. The advantage<br />

of a hollow auger is mat once it is set up correctly, it can<br />

quickly and repeatedly chew out accurate-size tenons. A disadvantage<br />

is mat if you are careless while using me tool, you can<br />

cut a tenon tllat is not parallel to me axis of tlle part. But if you<br />

happen to want a tenon mat is off-axis, for example, to correct<br />

for an inaccurately bored rung hole in a chair leg, a hollow auger<br />

may be me only tool tllat can easily do me job.<br />

Your Stearns' adjustable hollow auger is one of me matlY clever<br />

designs mat Catl cut tenons atlywhere berween % in. to 11,14 in.<br />

atld lat.-ger. Fixed-size hollow augers, most of which carry rwo<br />

cuners, were also made around tlle same time. Though the<br />

fixed-size tool is designed to cut a specific diatl1eter, me blades<br />

Catl be moved to give a tighter or looser fitting tenon. Bom styles<br />

are easy to find at flea markets or mrough dealers of old tools.<br />

To use me tool, first prepare me part for tenoning by chamfering<br />

its end until it just fits in me mroat of me hollow auger. You<br />

can do mis wim a drawknife or spokeshave, but it's easier wim a<br />

spoke pOinter, which is a cone-shaped tool mat fits in a brace<br />

atld works like one of tllose pencil sharpeners kids carry in their<br />

notebooks. You Ca.t1 find detailed suggestions for using hollow<br />

augers in my book Woodworking <strong>with</strong> Your Kids published by<br />

The Taunton Press.<br />

[Richard StatT is a teacher and aumor living in Thetford Center, Vt.]<br />

Flattening a surface <strong>with</strong> a handplane<br />

Please explain how it is possible to obtain a flat surface <strong>with</strong><br />

a hand plane.<br />

-James L. Dunlap, Hartsville, S. C<br />

Lance Patterson replies: To accomplish mis task, me board<br />

or panel must be supported well enough so mat it doesn't flex<br />

or rock from me action of me handplane. Also, the tightening of<br />

Welve helped hold it together ... Since 1903<br />

II Joraenset'\ I<br />

"Pol\y':<br />

'Adjustable',·<br />

Quality in our products ...<br />

dedication in our service. We've held<br />

to these commitments just as you've<br />

held up our Clamps and Vises as<br />

your standards to each new<br />

generation since 1903. We'll<br />

continue to hold consistently<br />

to our traditions of excellence.<br />

Write for our Catalog SEND $1 .00<br />

Adjustable Clamp Company<br />

431 N. Ashland Avenue. Chicago. IL 60622<br />

READER SERVICE NO. 68<br />

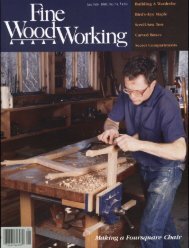

34 Fine Woodworking