05 | 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Polyurethanes | Elastomers<br />

with the polyether content. One of the key parameters is the<br />

modulus of the corresponding polyamide homopolymer.<br />

The modulus of polyamide homopolymers increases with<br />

the amide / methylene ratio. Indeed, a higher concentration<br />

of amide groups will lead to higher crystallinity and hence<br />

a more rigid material. Unfortunately, melting point of the<br />

material will also increase, together with moisture uptake<br />

and density. Absorption of water will have a significant impact<br />

on mechanical properties, for instance the modulus of PA6<br />

can be reduced by half under moist conditions. Increasing<br />

the density does not help towards designing lighter materials<br />

for demanding athletes. Another hurdle is that the solubility<br />

parameter of polyamide increases with the amide / methylene<br />

ratio, increasing the gap with the solubility parameter of the<br />

polyether, leading to a higher enthalpy of mixing. Mixing of<br />

the two blocks will thus be more difficult, leading to slower<br />

polymerisation, if any.<br />

Among the possible polyamides, the odd ones, meaning<br />

having an odd number of carbons, do have peculiar<br />

properties, as the positioning of the amide groups in the<br />

chain is important for structural order and packing efficiency.<br />

Among these polyamides, PA11 rapidly became the centre of<br />

our attention. Indeed, being an odd polyamide, its elementary<br />

lattice can theoretically lead to either a parallel or an antiparallel<br />

configuration of the chains with every amide group<br />

able to be engaged with another one through hydrogen bonds.<br />

Depending on the cooling procedure, crystals will either have<br />

a hexagonal arrangement or triclinic one. Usually, both are<br />

co-existing. A very interesting phenomenon is that the triclinic<br />

phase can change into a pseudo-hexagonal one under<br />

thermal or mechanical stress. Thus, the amount of energy<br />

needed to perform the crystalline transition will decrease<br />

the energy dissipated within the material, thus explaining the<br />

outstanding strain hardening behaviour of PA11 vs. PA12. In<br />

the case of PA12, an anti-parallel configuration of the chains<br />

is only observed because of the even number of carbon and<br />

the extra twist of the chains, necessary to optimise hydrogen<br />

bonding, leads to a γ-monoclinic structure. On a mesoscopic<br />

scale, the two materials exhibit noticeable differences:<br />

ringed spherulites can be observed for PA11, whereas coarse<br />

spherulites are the typical form for PA12.<br />

The next step was then to try and see whether it was<br />

possible to transpose the remarkable mechanical properties<br />

to a multi-segment block structure comprising a PA11 block<br />

with a very low molecular mass.<br />

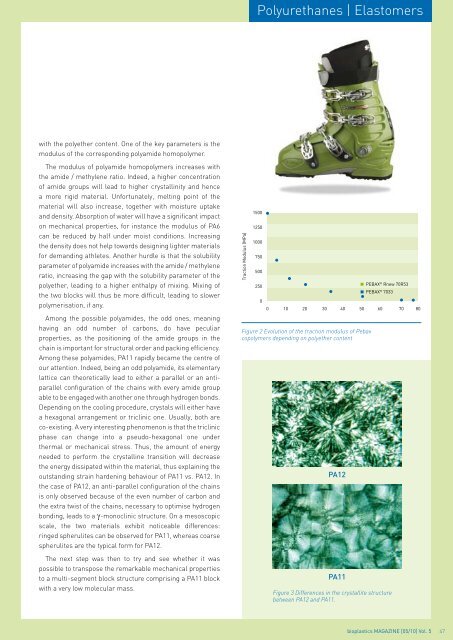

Traction Modulus (MPa)<br />

1500<br />

1250<br />

1000<br />

750<br />

500<br />

250<br />

0<br />

PEBAX ® Rnew 70R53<br />

PEBAX ® 7033<br />

0 10 20 30 40 50 60 70 80<br />

Figure 2 Evolution of the traction modulus of Pebax<br />

copolymers depending on polyether content<br />

PA12<br />

PA11<br />

Figure 3 Differences in the crystallite structure<br />

between PA12 and PA11.<br />

bioplastics MAGAZINE [<strong>05</strong>/10] Vol. 5 47