05 | 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Basics<br />

Basics of Bio-Polyolefins<br />

Polyethylene<br />

H H<br />

| |<br />

— C — C —<br />

| |<br />

H H<br />

n<br />

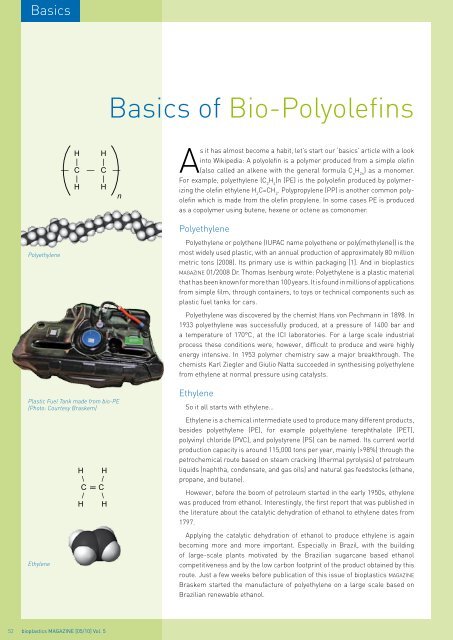

Plastic Fuel Tank made from bio-PE<br />

(Photo: Courtesy Braskem)<br />

Ethylene<br />

H H<br />

\ /<br />

C ═ C<br />

/ \<br />

H H<br />

As it has almost become a habit, let’s start our ‘basics’ article with a look<br />

into Wikipedia: A polyolefin is a polymer produced from a simple olefin<br />

(also called an alkene with the general formula C n<br />

H 2n<br />

) as a monomer.<br />

For example, polyethylene (C 2<br />

H 4<br />

)n (PE) is the polyolefin produced by polymerizing<br />

the olefin ethylene H 2<br />

C=CH 2<br />

. Polypropylene (PP) is another common polyolefin<br />

which is made from the olefin propylene. In some cases PE is produced<br />

as a copolymer using butene, hexene or octene as comonomer.<br />

Polyethylene<br />

Polyethylene or polythene (IUPAC name polyethene or poly(methylene)) is the<br />

most widely used plastic, with an annual production of approximately 80 million<br />

metric tons (2008). Its primary use is within packaging [1]. And in bioplastics<br />

MAGAZINE 01/2008 Dr. Thomas Isenburg wrote: Polyethylene is a plastic material<br />

that has been known for more than 100 years. It is found in millions of applications<br />

from simple film, through containers, to toys or technical components such as<br />

plastic fuel tanks for cars.<br />

Polyethylene was discovered by the chemist Hans von Pechmann in 1898. In<br />

1933 polyethylene was successfully produced, at a pressure of 1400 bar and<br />

a temperature of 170°C, at the ICI laboratories. For a large scale industrial<br />

process these conditions were, however, difficult to produce and were highly<br />

energy intensive. In 1953 polymer chemistry saw a major breakthrough. The<br />

chemists Karl Ziegler and Giulio Natta succeeded in synthesising polyethylene<br />

from ethylene at normal pressure using catalysts.<br />

Ethylene<br />

So it all starts with ethylene…<br />

Ethylene is a chemical intermediate used to produce many different products,<br />

besides polyethylene (PE), for example polyethylene terephthalate (PET),<br />

polyvinyl chloride (PVC), and polystyrene (PS) can be named. Its current world<br />

production capacity is around 115,000 tons per year, mainly (>98%) through the<br />

petrochemical route based on steam cracking (thermal pyrolysis) of petroleum<br />

liquids (naphtha, condensate, and gas oils) and natural gas feedstocks (ethane,<br />

propane, and butane).<br />

However, before the boom of petroleum started in the early 1950s, ethylene<br />

was produced from ethanol. Interestingly, the first report that was published in<br />

the literature about the catalytic dehydration of ethanol to ethylene dates from<br />

1797.<br />

Applying the catalytic dehydration of ethanol to produce ethylene is again<br />

becoming more and more important. Especially in Brazil, with the building<br />

of large-scale plants motivated by the Brazilian sugarcane based ethanol<br />

competitiveness and by the low carbon footprint of the product obtained by this<br />

route. Just a few weeks before publication of this issue of bioplastics MAGAZINE<br />

Braskem started the manufacture of polyethylene on a large scale based on<br />

Brazilian renewable ethanol.<br />

52 bioplastics MAGAZINE [<strong>05</strong>/10] Vol. 5