01 | 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

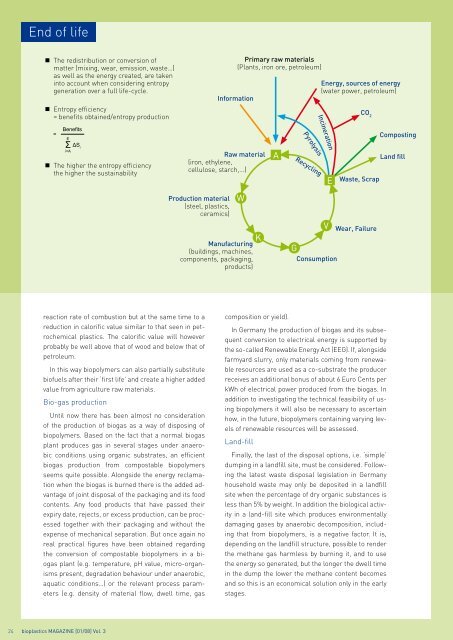

End of life<br />

• The redistribution or conversion of<br />

matter (mixing, wear, emission, waste…)<br />

as well as the energy created, are taken<br />

into account when considering entropy<br />

generation over a full life-cycle.<br />

• Entropy efficiency<br />

= benefits obtained/entropy production<br />

Information<br />

Primary raw materials<br />

(Plants, iron ore, petroleum)<br />

Energy, sources of energy<br />

(water power, petroleum)<br />

CO 2<br />

=<br />

Benefits<br />

E<br />

Σ ΔS i<br />

i=A<br />

• The higher the entropy efficiency<br />

the higher the sustainability<br />

Raw material<br />

(iron, ethylene,<br />

cellulose, starch,...)<br />

A<br />

Pyrolysis<br />

Recycling<br />

Incineration<br />

E<br />

Waste, Scrap<br />

Composting<br />

Land fill<br />

Production material<br />

(steel, plastics,<br />

ceramics)<br />

W<br />

Manufacturing<br />

(buildings, machines,<br />

components, packaging,<br />

products)<br />

K<br />

V<br />

G<br />

Consumption<br />

Wear, Failure<br />

reaction rate of combustion but at the same time to a<br />

reduction in calorific value similar to that seen in petrochemical<br />

plastics. The calorific value will however<br />

probably be well above that of wood and below that of<br />

petroleum.<br />

In this way biopolymers can also partially substitute<br />

biofuels after their ‘first life’ and create a higher added<br />

value from agriculture raw materials.<br />

Bio-gas production<br />

Until now there has been almost no consideration<br />

of the production of biogas as a way of disposing of<br />

biopolymers. Based on the fact that a normal biogas<br />

plant produces gas in several stages under anaerobic<br />

conditions using organic substrates, an efficient<br />

biogas production from compostable biopolymers<br />

seems quite possible. Alongside the energy reclamation<br />

when the biogas is burned there is the added advantage<br />

of joint disposal of the packaging and its food<br />

contents. Any food products that have passed their<br />

expiry date, rejects, or excess production, can be processed<br />

together with their packaging and without the<br />

expense of mechanical separation. But once again no<br />

real practical figures have been obtained regarding<br />

the conversion of compostable biopolymers in a biogas<br />

plant (e.g. temperature, pH value, micro-organisms<br />

present, degradation behaviour under anaerobic,<br />

aquatic conditions…) or the relevant process parameters<br />

(e.g. density of material flow, dwell time, gas<br />

composition or yield).<br />

In Germany the production of biogas and its subsequent<br />

conversion to electrical energy is supported by<br />

the so-called Renewable Energy Act (EEG). If, alongside<br />

farmyard slurry, only materials coming from renewable<br />

resources are used as a co-substrate the producer<br />

receives an additional bonus of about 6 Euro Cents per<br />

kWh of electrical power produced from the biogas. In<br />

addition to investigating the technical feasibility of using<br />

biopolymers it will also be necessary to ascertain<br />

how, in the future, biopolymers containing varying levels<br />

of renewable resources will be assessed.<br />

Land-fill<br />

Finally, the last of the disposal options, i.e. ‘simple’<br />

dumping in a landfill site, must be considered. Following<br />

the latest waste disposal legislation in Germany<br />

household waste may only be deposited in a landfill<br />

site when the percentage of dry organic substances is<br />

less than 5% by weight. In addition the biological activity<br />

in a land-fill site which produces environmentally<br />

damaging gases by anaerobic decomposition, including<br />

that from biopolymers, is a negative factor. It is,<br />

depending on the landfill structure, possible to render<br />

the methane gas harmless by burning it, and to use<br />

the energy so generated, but the longer the dwell time<br />

in the dump the lower the methane content becomes<br />

and so this is an economical solution only in the early<br />

stages.<br />

24 bioplastics MAGAZINE [<strong>01</strong>/08] Vol. 3