02 | 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Natural Fibres<br />

Go, Trabi Go!<br />

„Back to the future?“<br />

Article contributed by<br />

Rosemarie Karner<br />

It started about 50 years ago<br />

The Zwickau motor factory (AWZ) produced its first<br />

pilot series of small cars in 1957. In total 50 of the<br />

so-called P50‘s were built. Because the spirit of the<br />

times was still one of optimism and a bright future,<br />

a simple name like the P50 for such a ‘modern example<br />

of ingenious socialist engineering’ was hardly<br />

in keeping with the mood. It was therefore fortuitous<br />

that in October 1957 the Soviet Union launched the<br />

first „Sputnik“ earth satellite. This led to the adoption<br />

of the name „Trabant“, which, like „Sputnik“, means<br />

„travelling companion“. In 1964 the 601 model was<br />

introduced, with one of the main features being new<br />

bodywork. The car no longer looked quite so rotund,<br />

and there were small changes to the rear „fins“ that<br />

were popular at the time, especially in the USA. After<br />

1964 nothing on the Trabant really changed. Between<br />

1957 and 1991 a total of 3,051,385 Trabants<br />

were built (source: www.sueddeutsche.de)<br />

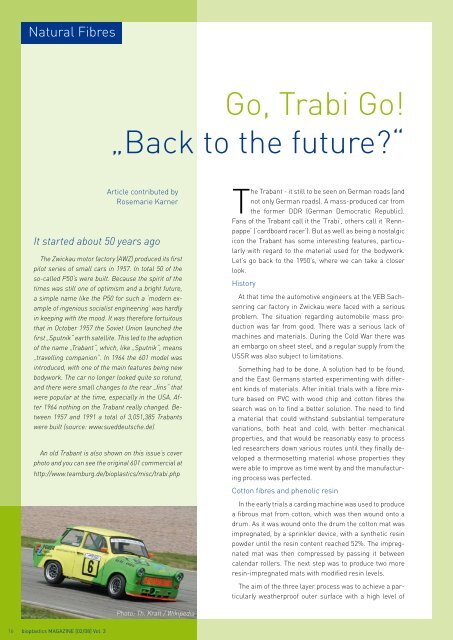

An old Trabant is also shown on this issue’s cover<br />

photo and you can see the original 601 commercial at<br />

http://www.teamburg.de/bioplastics/misc/trabi.php<br />

The Trabant - it still to be seen on German roads (and<br />

not only German roads). A mass-produced car from<br />

the former DDR (German Democratic Republic).<br />

Fans of the Trabant call it the ‘Trabi’, others call it ‘Rennpappe’<br />

(‘cardboard racer’). But as well as being a nostalgic<br />

icon the Trabant has some interesting features, particularly<br />

with regard to the material used for the bodywork.<br />

Let’s go back to the 1950‘s, where we can take a closer<br />

look.<br />

History<br />

At that time the automotive engineers at the VEB Sachsenring<br />

car factory in Zwickau were faced with a serious<br />

problem. The situation regarding automobile mass production<br />

was far from good. There was a serious lack of<br />

machines and materials. During the Cold War there was<br />

an embargo on sheet steel, and a regular supply from the<br />

USSR was also subject to limitations.<br />

Something had to be done. A solution had to be found,<br />

and the East Germans started experimenting with different<br />

kinds of materials. After initial trials with a fibre mixture<br />

based on PVC with wood chip and cotton fibres the<br />

search was on to find a better solution. The need to find<br />

a material that could withstand substantial temperature<br />

variations, both heat and cold, with better mechanical<br />

properties, and that would be reasonably easy to process<br />

led researchers down various routes until they finally developed<br />

a thermosetting material whose properties they<br />

were able to improve as time went by and the manufacturing<br />

process was perfected.<br />

Cotton fibres and phenolic resin<br />

In the early trials a carding machine was used to produce<br />

a fibrous mat from cotton, which was then wound onto a<br />

drum. As it was wound onto the drum the cotton mat was<br />

impregnated, by a sprinkler device, with a synthetic resin<br />

powder until the resin content reached 52%. The impregnated<br />

mat was then compressed by passing it between<br />

calendar rollers. The next step was to produce two more<br />

resin-impregnated mats with modified resin levels.<br />

The aim of the three layer process was to achieve a particularly<br />

weatherproof outer surface with a high level of<br />

Photo: Th. Kraft / Wikipedia<br />

16 bioplastics MAGAZINE [<strong>02</strong>/08] Vol. 3