02 | 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Natural Fibres<br />

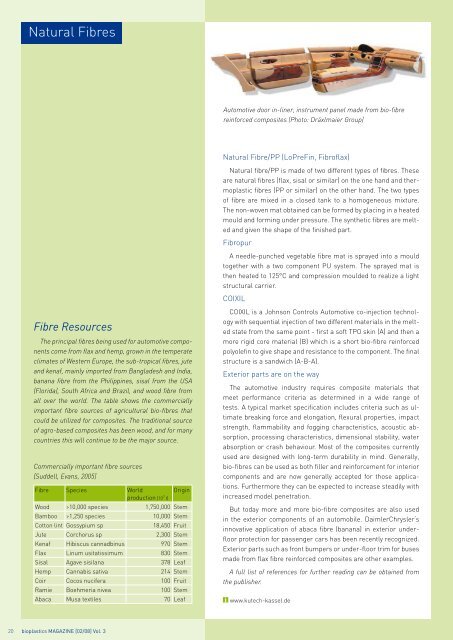

Automotive door in-liner, instrument panel made from bio-fibre<br />

reinforced composites (Photo: Dräxlmaier Group)<br />

Natural Fibre/PP (LoPreFin, Fibroflax)<br />

Natural fibre/PP is made of two different types of fibres. These<br />

are natural fibres (flax, sisal or similar) on the one hand and thermoplastic<br />

fibres (PP or similar) on the other hand. The two types<br />

of fibre are mixed in a closed tank to a homogeneous mixture.<br />

The non-woven mat obtained can be formed by placing in a heated<br />

mould and forming under pressure. The synthetic fibres are melted<br />

and given the shape of the finished part.<br />

Fibropur<br />

A needle-punched vegetable fibre mat is sprayed into a mould<br />

together with a two component PU system. The sprayed mat is<br />

then heated to 125°C and compression moulded to realize a light<br />

structural carrier.<br />

COIXIL<br />

Fibre Resources<br />

The principal fibres being used for automotive components<br />

come from flax and hemp, grown in the temperate<br />

climates of Western Europe, the sub-tropical fibres, jute<br />

and kenaf, mainly imported from Bangladesh and India,<br />

banana fibre from the Philippines, sisal from the USA<br />

(Florida), South Africa and Brazil, and wood fibre from<br />

all over the world. The table shows the commercially<br />

important fibre sources of agricultural bio-fibres that<br />

could be utilized for composites. The traditional source<br />

of agro-based composites has been wood, and for many<br />

countries this will continue to be the major source.<br />

Commercially important fibre sources<br />

[Suddell, Evans, 2005]<br />

Fibre Species World<br />

production [10 3 t]<br />

Origin<br />

Wood >10,000 species 1,750,000 Stem<br />

Bamboo >1,250 species 10,000 Stem<br />

Cotton lint Gossypium sp<br />

18,450 Fruit<br />

Jute Corchorus sp 2,300 Stem<br />

Kenaf Hibiscus cannadbinus 970 Stem<br />

Flax Linum usitatissimum 830 Stem<br />

Sisal Agave sisilana 378 Leaf<br />

Hemp Cannabis sativa 214 Stem<br />

Coir Cocos nucifera 100 Fruit<br />

Ramie Boehmeria nivea 100 Stem<br />

Abaca Musa textiles 70 Leaf<br />

COIXIL is a Johnson Controls Automotive co-injection technology<br />

with sequential injection of two different materials in the melted<br />

state from the same point - first a soft TPO skin (A) and then a<br />

more rigid core material (B) which is a short bio-fibre reinforced<br />

polyolefin to give shape and resistance to the component. The final<br />

structure is a sandwich (A-B-A).<br />

Exterior parts are on the way<br />

The automotive industry requires composite materials that<br />

meet performance criteria as determined in a wide range of<br />

tests. A typical market specification includes criteria such as ultimate<br />

breaking force and elongation, flexural properties, impact<br />

strength, flammability and fogging characteristics, acoustic absorption,<br />

processing characteristics, dimensional stability, water<br />

absorption or crash behaviour. Most of the composites currently<br />

used are designed with long-term durability in mind. Generally,<br />

bio-fibres can be used as both filler and reinforcement for interior<br />

components and are now generally accepted for those applications.<br />

Furthermore they can be expected to increase steadily with<br />

increased model penetration.<br />

But today more and more bio-fibre composites are also used<br />

in the exterior components of an automobile. DaimlerChrysler‘s<br />

innovative application of abaca fibre (banana) in exterior underfloor<br />

protection for passenger cars has been recently recognized.<br />

Exterior parts such as front bumpers or under-floor trim for buses<br />

made from flax fibre reinforced composites are other examples.<br />

A full list of references for further reading can be obtained from<br />

the publisher.<br />

www.kutech-kassel.de<br />

20 bioplastics MAGAZINE [<strong>02</strong>/08] Vol. 3