crossmax slr disc 09 - lesrouleuxdewailly - Free

crossmax slr disc 09 - lesrouleuxdewailly - Free

crossmax slr disc 09 - lesrouleuxdewailly - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical<br />

Manual<br />

20<strong>09</strong>

02<br />

20<strong>09</strong><br />

WWW.TECH-MAVIC.COM<br />

CONTENTS<br />

03.<br />

WWW.TECH-MAVIC.COM<br />

04>36. MAVIC ® WHEELS<br />

04. COSMIC CARBONE SL <strong>09</strong><br />

05. COSMIC CARBONE SLR<br />

06. COMETE ROAD <strong>09</strong><br />

07. KSYRIUM ELITE <strong>09</strong><br />

08. R-SYS PREMIUM<br />

<strong>09</strong>. CROSSMAX SLR DISC <strong>09</strong><br />

10. CROSSMAX SLR DISC <strong>09</strong> CENTER-LOCK<br />

11. CROSSMAX SLR DISC <strong>09</strong> 20MM<br />

12. CROSSMAX SLR DISC <strong>09</strong> LEFTY<br />

13. CROSSRIDE UB/DISC<br />

14. CROSSRIDE DISC<br />

15. CROSSMAX ST DISC <strong>09</strong><br />

16. CROSSMAX ST DISC <strong>09</strong> CENTER-LOCK<br />

17. CROSSLINE<br />

18. CROSSLINE CENTER-LOCK<br />

19. CROSSMAX SX <strong>09</strong><br />

20. CROSSMAX SX <strong>09</strong> CENTER-LOCK<br />

21. DEETRAKS <strong>09</strong> & DEETRAKS <strong>09</strong> 12X150<br />

22. DEEMAX <strong>09</strong> & DEEMAX <strong>09</strong> 12X150<br />

23. DEEMAX <strong>09</strong> SSC<br />

24>45. WHEEL MAINTENANCE<br />

25>30. HUB MAINTENANCE<br />

31>45. WHEEL BUILDING/REPLACING SPOKES AND RIMS<br />

46>48. SYSTEMS & ACCESSORIES<br />

46. WINTECH FS <strong>09</strong><br />

47. WINTECH ULTIMATE<br />

48. TROUBLESHOOTING<br />

49>51.<br />

TOOLS<br />

THIS DOCUMENT ONLY COVERS NEW PRODUCTS FOR 20<strong>09</strong>.<br />

THIS DOCUMENT UPDATES YOUR TECHNICAL INFORMATION AND SHOULD THEREFORE BE KEPT CAREFULLY, WITH NO TIME<br />

LIMITATION, WITH THE MANUALS FROM PREVIOUS YEARS.<br />

ALL INFORMATION ON PRODUCTS ALREADY INCLUDED IN PREVIOUS RANGES CAN BE FOUND IN THE TECHNICAL MANUALS<br />

PUBLISHED SINCE 1997.<br />

PLEASE VISIT THE INTERNET SITE www.tech-mavic.com TO FIND ALL EDITIONS OF THIS MANUAL PUBLISHED SINCE 1997.

www.tech-mavic.com<br />

03<br />

This website (in French, English, German, Spanish, Italian and Japanese) is at your complete disposal. All information about Mavic products released<br />

since 1997 is available in PDF format and downloadable from this site that is both easy to access and simple to use.<br />

Visit: www.tech-mavic.com where you will find all this information. To connect to this website you will need a user name and password:<br />

French User name: mavic-fr<br />

Password: detaillant<br />

Spanish User name: mavic-es<br />

Password: detallista<br />

English User name: mavic-com<br />

Password: dealer<br />

Italian User name: mavic-it<br />

Password: dettaglianti<br />

German User name: mavic-de<br />

Password: haendler<br />

Japanese User name: mavic-jp<br />

Password: dealer<br />

Among other things on the website, you will find:<br />

• Full technical details on all the Mavic products marketed since 1997 - wheels, rims, components - set out by <strong>disc</strong>ipline and by product;<br />

• 4 recap charts of spoke lengths and references for all our wheels, which will help you to manage your spoke stock;<br />

• A program for calculating spoke length: starting with a Mavic rim, select the drilling and lacing pattern and the width of your hub, as well as the<br />

diameter of the flanges and the distances between the flange and the frame or fork support; the spoke length required to build your wheel will be<br />

calculated automatically.<br />

We hope that this tool will meet your needs. Do not hesitate to point out any malfunctions you identify or improvements that you would like to see.

COSMIC CARBONE SL <strong>09</strong><br />

04<br />

USE: use only on a road bike. Any other use (such as on<br />

a tandem, cyclo-cross bike, or off-road use...) is highly<br />

inadvisable, is the sole responsibility of the user and voids<br />

the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

780 g<br />

Rear M10: 975 g<br />

Rear ED10: 960 g<br />

WHEEL REFERENCES<br />

Front: 995 530 10<br />

Rear M10: 996 531 11<br />

Rear ED10: 995 532 12<br />

Pair M10: 995 533 14<br />

Pair ED10: 995 534 14<br />

RIMS<br />

REFERENCES: Front: 996 840 10<br />

Rear: 996 840 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 55 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: ETRTO 622 x 13C<br />

Recommended tire width: 19 to 28 mm<br />

HUBS<br />

When replacing the rear rim:<br />

1. With the valve hole near you, turn the rim so that the “infobloc” label can be seen<br />

2. The first spoke to the right of the valve hole is a non-traction driving spoke and should be inserted in the drive side of the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40052<br />

M40078<br />

M40759<br />

M40063<br />

M40075<br />

M40578<br />

M40591 (ED10)<br />

M40592 (M10)<br />

324 130 01<br />

M40676<br />

M40578 995 000 01<br />

323 860 01<br />

M40067<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

996 841 01, length 289 mm (per 8, with nipples)<br />

996 842 01, length 306 mm (per 10, with nipples)<br />

996 843 01, length 288 mm (per 10, with nipples)<br />

FEATURES:<br />

Black steel straight pull spokes with ABS spoke nipples<br />

LACING PATTERN:<br />

Front: radial<br />

Rear: crossed 2 drive side, radial non-drive side<br />

TENSION:<br />

Front: 120 to 140 kg<br />

Rear drive side: 140 to 160 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

• BR 301 front quick-release skewer 996 939 01<br />

• BR 301 rear quick-release skewer 996 940 01<br />

• ED10 12D locking ring M40640 (with rear wheel ED10)<br />

• <strong>Free</strong> play adjustment wrench M40123 (with rear wheel)<br />

• Spoke wrench M40001 (with rear wheel)<br />

• Aerodynamic spoke wrench M40567 (with rear wheel)<br />

• Valve extender M40013<br />

• Rim tape<br />

• User guide<br />

MAINTENANCE<br />

• Replacing the front axle<br />

• Replacing the front bearings<br />

• Replacing the rear axle<br />

• Replacing the free wheel body<br />

• Replacing the rear bearings<br />

• Replacing a spoke<br />

• Replacing the front rim<br />

• Replacing the rear rim<br />

See 2005 TM, page 20<br />

See 2005 TM, page 20<br />

See 2003 TM, page 19<br />

See 2003 TM, page 21<br />

See 2003 TM, page 22<br />

See 2005 TM, page 23<br />

See 2005 TM, page 24<br />

See 2005 TM, page 27<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

COSMIC CARBONE SLR<br />

05<br />

USE: use only on a road bike. Any other use (such as on<br />

a tandem, cyclo-cross bike, or off-road use...) is highly<br />

inadvisable, is the sole responsibility of the user and voids<br />

the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

725 g<br />

Rear M10: 885 g<br />

Rear ED10: 870 g<br />

WHEEL REFERENCES<br />

Front: 995 540 10<br />

Rear M10: 996 541 11<br />

Rear ED10: 995 542 12<br />

Pair M10: 995 543 14<br />

Pair ED10: 995 544 14<br />

RIMS<br />

REFERENCES: Front: 996 834 10<br />

Rear: 996 834 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 55 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: ETRTO 622 x 13C<br />

Recommended tire width: 19 to 28 mm<br />

When replacing the rear rim:<br />

The side of the rim where the spoke holes are the nearest to the leaking edge is the drive side.<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40078<br />

996 033 01<br />

M40063<br />

996 839 01<br />

996 032 01<br />

996 035 01 996 034 01<br />

M40578<br />

995 000 01<br />

M40592 (M10)<br />

M40591 (ED10)<br />

M40067 324 130 01<br />

M40077<br />

996 839 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear non-drive side:<br />

Drive side:<br />

996 835 01, R2R spokes, (per 5, with ABS nipples)<br />

996 836 01, R2R spokes, (per 5, with ABS nipples)<br />

FEATURES:<br />

Unidirectional R2R carbon spokes (rim to rim), ABS nipples<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front: 80 to 100 kg<br />

Rear drive side: 90 to 110 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

• BR 601 front quick-release M40149<br />

• BR 601 rear quick-release M40150<br />

• Computer magnet 996 245 01 (with front wheel)<br />

• <strong>Free</strong> play adjustment wrench M40123 (with rear wheel)<br />

• Aerodynamic spoke wrench M40567 (with rear wheel)<br />

• Spoke wrench M40001 (with rear wheel)<br />

• Valve extender M40013<br />

• Rim tape<br />

• ED10 12D locking ring M40640 (with rear wheel ED10)<br />

• User guide and warranty card<br />

MAINTENANCE<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2005 TM, page 20<br />

See 2008 TM, page 23<br />

See 2003 TM, page 21<br />

See 2008 TM, page 24<br />

See page 32<br />

See page 33<br />

See pages 34/35<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

COMETE ROAD <strong>09</strong><br />

06<br />

USE: use only on a road bike. Any other use (such as on<br />

a tandem, cyclo-cross bike, or off-road use...) is highly<br />

inadvisable, is the sole responsibility of the user and voids<br />

the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

M10: 1165 g<br />

ED10: 1150 g<br />

WHEEL REFERENCES<br />

M10: 996 216 11<br />

ED10: 996 217 12<br />

RIMS<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: ETRTO 622 x 13C<br />

Recommended tire width: 19 to 28 mm<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40077<br />

995 000 01<br />

M40067<br />

M40592 (M10)<br />

M40591 (ED10)<br />

324 130 01<br />

M40579<br />

996 833 01<br />

ACCESSORIES<br />

WHEEL SUPPLIED WITH:<br />

MAINTENANCE<br />

• BR 601 rear quick-release M40150<br />

• ED10 12D locking ring M40640 (with rear wheel ED10)<br />

• Rim tape<br />

• Valve extender 323 634 01<br />

• User guide<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

See 2008 TM, page 23<br />

See 2003 TM, page 21<br />

See 2008 TM, page 24<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

KSYRIUM ELITE <strong>09</strong><br />

07<br />

USE: use only on a road bike. Any other use<br />

(such as on a tandem, cyclo-cross bike, or<br />

off-road use...) is highly inadvisable, is the<br />

sole responsibility of the user and voids<br />

the Mavic warranty.<br />

Recommended maximum weight of the<br />

cyclist and his equipment: 100 kg.<br />

WHEEL WEIGHTS<br />

Ø 700 WITHOUT<br />

QUICK-RELEASE<br />

SKEWER<br />

Front:<br />

675 g<br />

Rear M10: 890 g<br />

Rear ED10: 875 g<br />

WHEEL WEIGHTS<br />

Ø 650 WITHOUT<br />

QUICK-RELEASE<br />

SKEWER<br />

Front:<br />

640 g<br />

Rear M10: 805 g<br />

Rear ED10: 790 g<br />

BLACK WHEEL REFERENCES:<br />

Ø 700 Ø 650<br />

Front: 996 155 10 996 165 10<br />

Rear M10: 996 156 11 996 166 11<br />

Rear ED10: 996 157 12 996 167 12<br />

Pair M10: 996 158 14 996 168 14<br />

Pair ED10: 996 159 14 996 169 14<br />

SILVER WHEEL<br />

REFERENCES:<br />

Front: 996 160 10<br />

Rear M10: 996 161 11<br />

Rear ED10: 996 162 12<br />

Pair M10: 996 163 14<br />

Pair ED10: 996 164 14<br />

RIMS<br />

REFERENCES:<br />

Black: Front: 996 855 10<br />

Rear: 996 855 13<br />

Silver: Front: 996 863 10<br />

Rear: 996 863 13<br />

Ø 650 (Black): Front: 996 869 10<br />

Rear: 996 869 13<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 700: ETRTO 622 x 15C<br />

Ø 650: ETRTO 571 x 15C<br />

Recommended tire width: 19 to 32 mm<br />

HUBS<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the left of the valve hole<br />

2. The first spoke to the right of the valve hole is a driving spoke and should be inserted in the non-drive side of the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40318<br />

996 861 01<br />

M40063<br />

M40063<br />

M40578 995 000 01<br />

M40591 (ED10)<br />

M40592 (M10)<br />

324 130 01<br />

996 862 01<br />

M40660<br />

M40067<br />

As the front hub is made up of three parts, maintenance operations (replacing the axle or bearings) must always be carried out on the assembled wheel (hub,<br />

rim and spokes assembled).<br />

WHEEL BUILDING<br />

REFERENCES<br />

AND LENGTHS:<br />

Black<br />

Silver<br />

Front<br />

Rear drive side<br />

Rear non-drive side<br />

Front<br />

Rear drive side<br />

Rear non-drive side<br />

Ø 650 Black Front<br />

Rear drive side<br />

Rear non-drive side<br />

996 856 01, length 284 mm, (per 9, integrated nipples)<br />

996 857 01, length 276 mm, (per 10, integrated nipples)<br />

996 858 01, length 301 mm, (per 10, integrated nipples)<br />

996 864 01, length 284 mm, (per 9, integrated nipples)<br />

996 865 01, length 276 mm, (per 10, integrated nipples)<br />

996 866 01, length 301 mm, (per 10, integrated nipples)<br />

996 870 01, length 259 mm, (per 9, integrated nipples)<br />

996 871 01, length 251 mm, (per 10, integrated nipples)<br />

996 872 01, length 280 mm, (per 10, integrated nipples)<br />

FEATURES:<br />

Black or silver stainless steel straight pull spokes with integrated, self-locking M7<br />

screws.<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

• BR 301 front quick-release skewer 996 939 01<br />

• BR 301 rear quick-release skewer 996 940 01<br />

• ED10 12D locking ring M40640 (with rear wheel ED10)<br />

• <strong>Free</strong> play adjustment wrench M40123 (with rear wheel)<br />

• Spoke wrench M40494 (with rear wheel)<br />

• User guide<br />

LACING PATTERN:<br />

Front: radial<br />

Rear: Isopulse<br />

MAINTENANCE<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

TENSION:<br />

Front: 110 to 130 kg<br />

Rear drive side: 125 to 145 kg<br />

See 2005 TM, page 20<br />

See 2007 TM, page 20<br />

See 2003 TM, page 21<br />

See 2004 TM, page 22<br />

See 2008 TM, page 25<br />

See 2008 TM, page 25<br />

See page 31<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

R-SYS PREMIUM<br />

08<br />

USE: use only on a road bike. Any other use (such as on<br />

a tandem, cyclo-cross bike, or off-road use...) is highly<br />

inadvisable, is the sole responsibility of the user and voids<br />

the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

575 g<br />

Rear M10: 800 g<br />

Rear ED10: 785 g<br />

WHEEL REFERENCES<br />

Front: 996 248 10<br />

Rear M10: 996 249 11<br />

Rear ED10: 996 250 12<br />

Pair M10: 996 378 14<br />

Pair ED10: 996 401 14<br />

RIMS<br />

REFERENCES:<br />

Clincher : Front: 996 848 10<br />

Rear: 996 848 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: ETRTO 622 x 15C<br />

Recommended tire width: 19 to 32 mm<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-driving spoke and should be inserted in the drive side<br />

of the hub<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 938 01<br />

M40078<br />

M40052<br />

996 853 01<br />

M40063<br />

996 938 01<br />

M40578<br />

996 035 01<br />

995 000 01<br />

M40067<br />

M40591 (ED10)<br />

M40592 (M10)<br />

995 469 01<br />

M40077<br />

996 854 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Drive side:<br />

Non-drive side:<br />

996 849 01, length 285 mm, (per 9, integrated nipples)<br />

996 073 01, length 294.5 mm, (per 10, integrated nipples)<br />

996 850 01, length 284 mm, (per 10, integrated nipples)<br />

FEATURES:<br />

Front and rear non-drive side: carbon tubular spokes<br />

(TraComp)<br />

Rear drive side: black Zicral straight pull spokes with<br />

integrated, self-locking nipples<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

• BR 601 Titanium front quick-release skewer 323 485 01<br />

• BR 601 Titanium rear quick-release skewer 323 486 01<br />

• Computer magnet built in the spoke (front wheel)<br />

• <strong>Free</strong> play adjustment wrench M40123 (with rear wheel)<br />

• Spoke wrench 996 079 01 (with rear wheel)<br />

• Zicral spoke wrench M40567 (with rear wheel)<br />

• TraComp ring tool 996 080 01<br />

• ED10 12D locking ring M40640 (with rear wheel ED10)<br />

• Wheel bags M40135<br />

• User guide<br />

LACING PATTERN:<br />

Front: radial, TraComp system<br />

Rear: crossed 2 drive side, radial non-drive side,<br />

TraComp system<br />

MAINTENANCE<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Important note for fitting TraComp spokes<br />

Identifying a damaged TraComp carbon spoke<br />

Removing/Refitting the TraComp ring<br />

Truing and replacing a TraComp spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

TENSION:<br />

Front: 70 to 100 kg<br />

Rear drive side: 90 to 110 kg<br />

See 2005 TM, page 20<br />

See 2008 TM, page 24<br />

See 2003 TM, page 21<br />

See 2008 TM, page 24<br />

See 2008 TM, page 28<br />

See 2008 TM, page 28<br />

See page 36<br />

See 2008 TM, page 30<br />

See 2008 TM, page 30<br />

See 2008 TM, page 31<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com<br />

Never turn a TraComp spoke nipple with having first removed the TraComp rings from the hub, otherwise the spoke may be irreversible damaged.<br />

Never fit a computer magnet other than the one integrated.<br />

Only transport the wheels in the wheel bags supplied. Avoid side shocks to the TraComp spokes.

CROSSMAX SLR DISC <strong>09</strong><br />

STANDARD<br />

INTERNATIONAL<br />

<strong>09</strong><br />

USE: use only on a Cross Country MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, free-ride or downhill bike…) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 85 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

690 g<br />

Rear:<br />

830 g<br />

WHEEL REFERENCES<br />

Front: 996 412 10<br />

Rear: 996 413 13<br />

Pair: 996 414 14<br />

RIMS<br />

REFERENCES: Front: 996 873 10<br />

Rear: 996 873 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 17C compatible and Tubeless UST.<br />

Recommended tire width: 1.0’’ to 2.1’’<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 941 01<br />

996 885 01<br />

996 882 01<br />

M40075<br />

995 470 01<br />

M40457<br />

995 399 01<br />

995 000 01<br />

324 303 01<br />

M40067<br />

M40580<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 376 01, length 261 mm, (per 12 + 3 red, integrated nipples)<br />

995 377 01, length 248 mm, (per 12 + 1 red, integrated nipples)<br />

996 874 01, length 263 mm, (per 12 + 2 red, integrated nipples)<br />

FEATURES:<br />

Black Zicral double butted straight pull spokes (including two<br />

decorated per wheel) with integrated, self-locking M7 aluminum<br />

spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 120 to 140 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 Titanium front quick-release skewer 995 388 01<br />

• BX 601 Titanium rear quick-release skewer 995 389 01<br />

• Computer magnet M40540 (with front wheel)<br />

• Spoke wrench M40494 (with rear wheel)<br />

• Axle reducers 15=>9 mm 996 941 01 (with front wheel)<br />

• UST valves 995 282 01<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Front hub assembly diameter conversion<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 25<br />

See page 26<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See page 37<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX SLR DISC <strong>09</strong> Center-Lock<br />

10<br />

CENTER<br />

LOCK<br />

USE: use only on a Cross Country MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, free-ride or downhill bike…) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 85 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

690 g<br />

Rear:<br />

820 g<br />

WHEEL REFERENCES<br />

Front: 996 499 10<br />

Rear: 996 500 13<br />

Pair: 996 501 14<br />

RIMS<br />

REFERENCES: Front: 996 873 10<br />

Rear: 996 873 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 17C compatible and Tubeless UST.<br />

Recommended tire width: 1.0’’ to 2.1’’<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side.<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 941 01<br />

996 883 01<br />

996 886 01<br />

M40075<br />

995 470 01<br />

M40457<br />

995 642 01<br />

324 303 01<br />

995 000 01<br />

M40067<br />

M40580<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 376 01, length 261 mm, (per 12 + 3 red, integrated nipples)<br />

995 377 01, length 248 mm, (per 12 + 1 red, integrated nipples)<br />

996 874 01, length 263 mm, (per 12 + 2 red, integrated nipples)<br />

FEATURES:<br />

Black Zicral double butted straight pull spokes (including two<br />

decorated per wheel) with integrated, self-locking M7 aluminum<br />

spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 120 to 140 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 Titanium front quick-release skewer 995 388 01<br />

• BX 601 Titanium rear quick-release skewer 995 389 01<br />

• Computer magnet M40540 (with front wheel)<br />

• Spoke wrench M40494 (with rear wheel)<br />

• Axle reducers 15=>9 mm 996 941 01 (with front wheel)<br />

• UST valves 995 282 01<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Front hub assembly diameter conversion<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 25<br />

See page 26<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See page 37<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX SLR DISC <strong>09</strong> 20 MM<br />

11<br />

STANDARD<br />

INTERNATIONAL<br />

USE: use only on a Cross Country MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, free-ride or downhill bike…) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 85 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

695 g<br />

Rear:<br />

830 g<br />

WHEEL REFERENCES<br />

Front: 996 520 10<br />

Rear: 996 413 13<br />

Pair: 996 521 14<br />

RIMS<br />

REFERENCES: Front: 996 873 10<br />

Rear: 996 873 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 17C compatible and Tubeless UST.<br />

Recommended tire width: 1.0’’ to 2.1’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side.<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40179<br />

996 040 01<br />

M40075<br />

995 470 01<br />

M40457<br />

995 000 01<br />

M40067<br />

M40580<br />

995 399 01<br />

324 303 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 376 01, length 261 mm, (per 12 + 3 red, integrated nipples)<br />

995 377 01, length 248 mm, (per 12 + 1 red, integrated nipples)<br />

996 874 01, length 263 mm, (per 12 + 2 red, integrated nipples)<br />

FEATURES:<br />

Black Zicral double butted straight pull spokes (front and rear nondrive<br />

side) (including two decorated per wheel) with integrated,<br />

self-locking M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 120 to 140 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 Titanium rear quick-release skewer 995 389 01<br />

• Computer magnet M40540<br />

• Spoke wrench M40494 (with rear wheel)<br />

• UST valves 995 282 01<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2008 TM, page 24<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See page 37<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

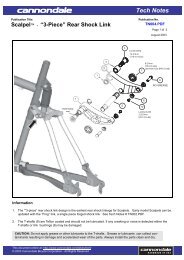

CROSSMAX SLR DISC <strong>09</strong> LEFTY<br />

12<br />

STANDARD<br />

INTERNATIONAL<br />

USE: use only on a Cross Country MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, free-ride or downhill bike…) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 85 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

695 g<br />

Rear:<br />

830 g<br />

WHEEL REFERENCES<br />

Front: 996 522 10<br />

Rear: 996 413 13<br />

Pair: 996 523 14<br />

RIMS<br />

REFERENCES: Front: 996 873 10<br />

Rear: 996 873 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 17C compatible and Tubeless UST.<br />

Recommended tire width: 1.0’’ to 2.1’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side.<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40777<br />

M40771<br />

M40075<br />

995 470 01<br />

M40457<br />

995 000 01<br />

M40067<br />

M40580<br />

995 399 01<br />

324 303 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 376 01, length 261 mm, (per 12 + 3 red, integrated nipples)<br />

995 377 01, length 248 mm, (per 12 + 1 red, integrated nipples)<br />

996 874 01, length 263 mm, (per 12 + 2 red, integrated nipples)<br />

FEATURES:<br />

Black Zicral double butted straight pull spokes (including two<br />

decorated per wheel) with integrated, self-locking M7 aluminum<br />

spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 120 to 140 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 Titanium rear quick-release skewer 995 389 01<br />

• Lefty assembly accessories M40777 (with front wheel)<br />

• Computer magnet M40540<br />

• Spoke wrench M40494 (with rear wheel)<br />

• UST valves 995 282 01<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Fitting and removing the front wheel on the fork<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2004 TM, page 18<br />

See page 26<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See page 37<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSRIDE UB/DISC <strong>09</strong><br />

STANDARD<br />

INTERNATIONAL<br />

13<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> brakes. Any other use (such as on a tandem,<br />

road bike, cyclo-cross bike, free-ride or downhill bike…) is<br />

highly inadvisable, is the sole responsibility of the user and<br />

voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

900 g<br />

Rear M10: 1040 g<br />

WHEEL REFERENCES<br />

STANDARD INTERNATIONAL<br />

Front: 996 403 10<br />

Rear: 996 404 13<br />

Pair: 996 405 14<br />

RIMS<br />

REFERENCES: Front and rear: 996 891 15<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 8.5 mm with valve adaptor 6.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 19C<br />

Recommended tire width: 1.1’’ to 2.3’’<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40318<br />

323 479 01<br />

323 484 01<br />

323 484 01<br />

M40660<br />

324 303 01<br />

995 000 01<br />

M40067<br />

323 480 01<br />

M40592<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear: 996 892 01, length 261 mm (per 12, with nipples)<br />

FEATURES:<br />

Silver stainless steel straight pull spokes with Self Lock system<br />

and conventional spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 100 to 120 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

• BR 101 front quick-release: M40350<br />

• BR 101 rear quick-release: M40351<br />

• Rim tape 559x20x0.6<br />

• User guide<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2004 TM, page 19<br />

See 2004 TM, page 20<br />

See 2007 TM, page 21<br />

See 2004 TM, page 22<br />

See 2004 TM, page 25<br />

See page 38<br />

See page 39<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSRIDE DISC<br />

STANDARD<br />

INTERNATIONAL<br />

CENTER<br />

LOCK<br />

14<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> brakes. Any other use (such as on a tandem,<br />

road bike, cyclo-cross bike, free-ride or downhill bike…) is<br />

highly inadvisable, is the sole responsibility of the user and<br />

voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

INT CL<br />

Front: 885 g 880 g<br />

Rear: 1020 g 1015 g<br />

WHEEL REFERENCES<br />

INT<br />

CL<br />

Front: 996 176 10 996 179 10<br />

Rear: 996 177 13 996 180 13<br />

Pair: 996 178 14 996 181 14<br />

RIMS<br />

REFERENCES: Front and rear: 996 890 15<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 8.5 mm with valve adaptor 6.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 19C<br />

Recommended tire width: 1.1’’ to 2.3’’<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40318<br />

323 479 01<br />

323 484 01<br />

M40660<br />

324 303 01<br />

323 484 01<br />

995 000 01<br />

M40067<br />

323 480 01<br />

M40592<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear: 996 875 01, length 261 mm (per 12, with nipples)<br />

WHEEL BUILDING<br />

FEATURES:<br />

Black steel straight pull spokes with Self Lock system and<br />

conventional spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 100 to 120 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

• BR 101 front quick-release: M40350<br />

• BR 101 rear quick-release: M40351<br />

• Rim tape 559x20x0.6<br />

• User guide<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2004 TM, page 19<br />

See 2004 TM, page 20<br />

See 2007 TM, page 21<br />

See 2004 TM, page 22<br />

See 2004 TM, page 25<br />

See page 38<br />

See page 39<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX ST DISC <strong>09</strong><br />

15<br />

STANDARD<br />

INTERNATIONAL<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> brakes. Any other use (such as on a tandem,<br />

road bike, cyclo-cross bike, free-ride or downhill bike…) is<br />

highly inadvisable, is the sole responsibility of the user and<br />

voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

745 g<br />

Rear:<br />

895 g<br />

WHEEL REFERENCES<br />

Front: 996 799 10<br />

Rear: 995 119 13<br />

Pair: 996 801 14<br />

RIMS<br />

REFERENCES: Front: 995 400 10<br />

Rear: 995 400 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 19C compatible and Tubeless UST.<br />

Recommended tire width: 1.1’’ to 2.3’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the left of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side of the hub<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 941 01<br />

996 885 01<br />

996 882 01<br />

M40075<br />

324 129 01<br />

M40457<br />

M40067<br />

M40580<br />

M40576<br />

995 000 01<br />

324 303 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 401 01, length 261 mm, (per 12 + 1 decorated, integrated nipples)<br />

995 402 01, length 248 mm, (per 12, integrated nipples)<br />

995 403 01, length 263 mm, (per 12 + 1 decorated, integrated nipples)<br />

FEATURES:<br />

Black Zicral round straight pull spokes (with one decorated per<br />

wheel) with integrated, self-locking M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 front quick-release M40140<br />

• BX 601 rear quick-release M40141<br />

• UST valves 995 282 01<br />

• Computer magnet M40540 (with front wheel)<br />

• Axle reducers 15 => 9 mm 996 941 01 (with front wheel)<br />

• M7 spoke wrench M40494 (with rear wheel)<br />

• Anti-ejection plugs 996 065 01 (with rear wheel)<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Front hub assembly diameter conversion<br />

Replacing the front axle and bearings<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 25<br />

See page 26<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See 2007 TM, page 22<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX ST DISC <strong>09</strong> Center-Lock<br />

CENTER<br />

LOCK<br />

16<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> brakes. Any other use (such as on a tandem,<br />

road bike, cyclo-cross bike, free-ride or downhill bike…) is<br />

highly inadvisable, is the sole responsibility of the user and<br />

voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

745 g<br />

Rear:<br />

890 g<br />

WHEEL REFERENCES<br />

Front: 996 800 10<br />

Rear: 995 145 13<br />

Pair: 996 802 14<br />

RIMS<br />

REFERENCES: Front: 995 400 10<br />

Rear: 995 400 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 19C compatible and Tubeless UST.<br />

Recommended tire width: 1.1’’ to 2.3’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the left of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side of the hub<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole should be inserted on the drive side in a marked hole on the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 941 01<br />

996 883 01<br />

996 886 01<br />

M40075<br />

324 129 01<br />

M40457<br />

323 863 01<br />

M40067<br />

995 000 01<br />

324 303 01<br />

M40580<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

995 401 01, length 261 mm, (per 12 + 1 decorated, integrated nipples)<br />

995 402 01, length 248 mm, (per 12, integrated nipples)<br />

995 403 01, length 263 mm, (per 12 + 1 decorated, integrated nipples)<br />

FEATURES:<br />

Black Zicral round straight pull spokes (with one decorated per<br />

wheel) with integrated, self-locking M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front: crossed 2 on both sides<br />

Rear: Isopulse<br />

TENSION:<br />

Front <strong>disc</strong> side: 120 to 140 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 front quick-release M40140<br />

• BX 601 rear quick-release M40141<br />

• UST valves 995 282 01<br />

• Computer magnet M40540 (with front wheel)<br />

• Axle reducers 15 => 9 mm 996 941 01 (with front wheel)<br />

• M7 spoke wrench M40494 (with rear wheel)<br />

• Anti-ejection plugs 996 065 01 (with rear wheel)<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Front hub assembly diameter conversion<br />

Replacing the front axle and bearings on the CL model<br />

Replacing the rear axle<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 25<br />

See page 26<br />

See 2007 TM, page 20<br />

See 2007 TM, page 21<br />

See 2003 TM, page 22<br />

See 2003 TM, page 24<br />

See 2007 TM, page 22<br />

See 2006 TM, page 17<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSLINE<br />

STANDARD<br />

INTERNATIONAL<br />

17<br />

USE: use only on a Enduro-<strong>Free</strong>ride MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, downhill bike…) is highly inadvisable, is the sole<br />

responsibility of the user and voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front: 970 g<br />

Rear: 1085 g<br />

WHEEL REFERENCES<br />

Front: 995 566 10<br />

Rear: 995 567 13<br />

Pair: 995 568 14<br />

RIMS<br />

REFERENCES: Front and rear: 996 902 15<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 8.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 21C compatible<br />

Recommended tire width: 2.1’’ to 2.5’’<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 908 01<br />

M40179<br />

996 994 01<br />

996 104 01<br />

996 203 01<br />

996 106 01<br />

M40076<br />

996 942 01<br />

996 107 01<br />

996 105 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear: 996 903 01, length 273 mm, (per 14, with nipples)<br />

FEATURES:<br />

Black steel round straight pull spokes with Self Lock system and<br />

conventional spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 101 rear quick-release M40351<br />

• Fork support kit 20 mm 996 994 01<br />

• Axle reducers 12=>9 mm 996 942 01<br />

• Rim tape<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings in the INT model<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2003 TM, page 18<br />

See page 30<br />

See page 29<br />

See page 30<br />

See 2004 TM, page 25<br />

See 2004 TM, page 28<br />

See 2004 TM, page 29<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSLINE Center-Lock<br />

CENTER<br />

LOCK<br />

18<br />

USE: use only on a Enduro-<strong>Free</strong>ride MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, downhill bike…) is highly inadvisable, is the sole<br />

responsibility of the user and voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front: 965 g<br />

Rear: 1080 g<br />

WHEEL REFERENCES<br />

Front: 996 230 10<br />

Rear: 996 231 13<br />

Pair: 996 232 14<br />

RIMS<br />

REFERENCES: Front: 996 902 15<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 8.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 21C compatible<br />

Recommended tire width: 2.1’’ to 2.5’’<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 9<strong>09</strong> 01<br />

M40179<br />

996 994 01<br />

996 900 01<br />

996 203 01<br />

996 106 01<br />

M40076<br />

996 942 01<br />

996 107 01<br />

996 105 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear: 996 903 01, length 273 mm, (per 14, with nipples)<br />

FEATURES:<br />

Black steel round straight pull spokes with Self Lock system and<br />

conventional spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 101 rear quick-release M40351<br />

• Fork support kit 20 mm 996 994 01<br />

• Axle reducers 12=>9 mm 996 942 01<br />

• Rim tape<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings in the CL model<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 28<br />

See page 25<br />

See page 29<br />

See page 30<br />

See 2004 TM, page 25<br />

See 2004 TM, page 28<br />

See 2004 TM, page 29<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX SX <strong>09</strong><br />

STANDARD<br />

INTERNATIONAL<br />

19<br />

USE: use only on a Enduro-<strong>Free</strong>ride MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, downhill bike…) is highly inadvisable, is the sole<br />

responsibility of the user and voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

825 g<br />

Rear:<br />

930 g<br />

WHEEL REFERENCES<br />

Front: 996 223 10<br />

Rear: 996 224 13<br />

Pair: 996 225 14<br />

RIMS<br />

REFERENCES: Front: 996 893 10<br />

Rear: 996 893 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 21C compatible and Tubeless UST<br />

Recommended tire width: 2.1’’ to 2.5’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the left of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side of the hub<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-driving spoke and should be inserted in the drive side of the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40179<br />

996 040 01<br />

996 104 01<br />

996 203 01<br />

996 106 01<br />

M40076<br />

996 942 01<br />

996 107 01<br />

996 105 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear non-drive side:<br />

Rear drive side:<br />

995 437 01, length 255 mm, (per 12 + 2 pad-printed, integrated nipples)<br />

995 438 01, length 247 mm, (per 12, integrated nipples)<br />

FEATURES:<br />

Gray Zicral round straight pull spokes with integrated, self-locking<br />

M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 rear quick-release M40141<br />

• Axle reducers 12=>9 mm 996 942 01<br />

• UST valves 995 282 01<br />

• Computer magnet M40540 (with front wheel)<br />

• M7 spoke wrench M40494 (with rear wheel)<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings in the INT model<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2008 TM, page 24<br />

See page 25<br />

See page 29<br />

See page 30<br />

See 2003 TM, page 24<br />

See 2003 TM, page 29<br />

See 2003 TM, page 30<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

CROSSMAX SX <strong>09</strong> Center-Lock<br />

CENTER<br />

LOCK<br />

20<br />

USE: use only on a Enduro-<strong>Free</strong>ride MTB fitted with <strong>disc</strong><br />

brakes. Any other use (such as on a tandem, road bike, cyclocross<br />

bike, downhill bike…) is highly inadvisable, is the sole<br />

responsibility of the user and voids the Mavic warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 100 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

Front:<br />

825 g<br />

Rear:<br />

920 g<br />

WHEEL REFERENCES<br />

Front: 996 507 10<br />

Rear: 996 508 13<br />

Pair: 996 5<strong>09</strong> 14<br />

RIMS<br />

REFERENCES: Front: 996 893 10<br />

Rear: 996 893 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 21C compatible and Tubeless UST<br />

Recommended tire width: 2.1’’ to 2.5’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the left of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side of the hub<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-driving spoke and should be inserted in the drive side of the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

996 898 01<br />

103 310 01<br />

103 261 01<br />

M40179<br />

996 900 01<br />

996 203 01<br />

996 106 01<br />

M40076<br />

996 942 01<br />

996 107 01<br />

996 105 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front and rear non-drive side:<br />

Rear drive side:<br />

995 437 01, length 255 mm, (per 12 + 2 pad-printed, integrated nipples)<br />

995 438 01, length 247 mm, (per 12, integrated nipples)<br />

FEATURES:<br />

Gray Zicral round straight pull spokes with integrated, self-locking<br />

M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 2 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 rear quick-release M40141<br />

• Axle reducers 12=>9 mm 996 942 01<br />

• UST valves 995 282 01<br />

• Computer magnet M40540 (with front wheel)<br />

• M7 spoke wrench M40494 (with rear wheel)<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings in the CL model<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See page 28<br />

See page 25<br />

See page 29<br />

See page 30<br />

See 2003 TM, page 24<br />

See 2003 TM, page 29<br />

See 2003 TM, page 30<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

DEETRAKS <strong>09</strong> and DEETRAKS <strong>09</strong> 12x150<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> or rim brakes. Any other use (such as on a<br />

tandem, road bike, cyclo-cross bike, …) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 115 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

9.5x135 12x150<br />

Front: 1085 g 1085 g<br />

Rear: 1170 g 1175 g<br />

WHEEL REFERENCES<br />

9.5x135 12x150<br />

Front: 996 197 10 996 197 10<br />

Rear: 996 198 13 996 221 13<br />

Pair: 996 199 14 996 222 14<br />

21<br />

STANDARD<br />

INTERNATIONAL<br />

RIMS<br />

REFERENCES: Front and rear: 996 925 15<br />

Ø VALVE HOLE<br />

RECOMMENDED TIRE WIDTH<br />

Ø: 8.5 mm<br />

Length.: 32 mm<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 25C compatible<br />

Recommended tire width: 2.3’’ to 3.0’’<br />

HUBS<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40179<br />

99690801<br />

99699401<br />

996 942 01<br />

996 104 01 (OLD : 135 mm) / 996 918 01 (OLD : 150 mm)<br />

996 107 01<br />

996 105 01<br />

M40076<br />

996 203 01<br />

996 106 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front non-<strong>disc</strong> side and rear non-drive side:<br />

Front <strong>disc</strong> side and rear drive side:<br />

996 926 01, length 263 mm (per 16, with nipples)<br />

996 927 01, length 261 mm (per 16, with nipples)<br />

FEATURES:<br />

Black steel round J-bent spokes with Self Lock system and<br />

conventional spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 3 on 2 sides, hot lacing.<br />

TENSION:<br />

Front <strong>disc</strong> side: 110 to 130 kg<br />

Rear drive side: 120 to 140 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BR 101 rear quick-release skewer M40351 (with 135 mm rear wheel<br />

only)<br />

• Fork support kit 20 mm 996 994 01<br />

• Axle reducers =>9 mm 996 942 01 (with 135 mm rear wheel only)<br />

• Rim tape<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing one spoke, front or rear rim<br />

See 2008 TM, page 24<br />

See page 25<br />

See page 29<br />

See page 30<br />

See page 40<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

DEEMAX <strong>09</strong> and DEEMAX <strong>09</strong> 12x150<br />

22<br />

STANDARD<br />

INTERNATIONAL<br />

USE: use only on a Cross Country or Cross Mountain MTB<br />

fitted with <strong>disc</strong> or rim brakes. Any other use (such as on a<br />

tandem, road bike, cyclo-cross bike, …) is highly inadvisable,<br />

is the sole responsibility of the user and voids the Mavic<br />

warranty.<br />

Recommended maximum weight of the cyclist and his<br />

equipment: 115 kg.<br />

WHEEL WEIGHTS WITHOUT<br />

QUICK-RELEASE SKEWER<br />

9.5x135 12x150<br />

Front: 1010 g 1010 g<br />

Rear: 1150 g 1160 g<br />

WHEEL REFERENCES<br />

9.5x135 12x150<br />

Front: 996 192 10 996 192 10<br />

Rear: 996 193 13 996 195 13<br />

Pair: 996 194 14 996 196 14<br />

RIMS<br />

REFERENCES: Front: 996 910 10<br />

Rear: 996 910 13<br />

Ø VALVE HOLE<br />

Ø: 6.5 mm<br />

Length.: 32 mm<br />

RECOMMENDED TIRE WIDTH<br />

Dimensions: Ø 26’’<br />

ETRTO 559 x 23C compatible and Tubeless UST.<br />

Recommended tire width: 2.3’’ to 3.0’’<br />

HUBS<br />

When replacing the front rim:<br />

1. With the valve hole near you, the raised indicator bump must be to the left of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-braking spoke and should be inserted in the <strong>disc</strong> side of the hub<br />

When replacing the rear rim:<br />

1. With the valve hole near you, the two raised indicator bumps must be to the right of the valve hole<br />

2. The spoke in the first hole to the right of the valve hole is a non-driving spoke and should be inserted in the drive side of the hub<br />

MAINTENANCE: Clean with a dry cloth or soap and water if necessary.<br />

Do not use a high-pressure washer.<br />

M40179<br />

996 917 01<br />

996 104 01 (OLD : 135 mm) / 996 918 01 (OLD : 150 mm)<br />

996 203 01 996 105 01<br />

M40076<br />

996 942 01<br />

996 107 01 996 106 01<br />

WHEEL BUILDING<br />

REFERENCES AND<br />

LENGTHS:<br />

Front:<br />

Rear drive side:<br />

Rear non-drive side:<br />

996 911 01, length 270 mm (per 14, integrated nipples)<br />

996 912 01, length 264.5 mm (per 16, integrated nipples)<br />

996 913 01, length 267.5 mm (per 16 integrated nipples)<br />

FEATURES:<br />

Black stainless steel round straight pull spokes with integrated,<br />

self-locking M7 aluminum spoke nipples.<br />

LACING PATTERN:<br />

Front and rear: crossed 3 on both sides<br />

TENSION:<br />

Front <strong>disc</strong> side: 100 to 120 kg<br />

Rear drive side: 110 to 130 kg<br />

ACCESSORIES<br />

WHEELS SUPPLIED WITH:<br />

MAINTENANCE<br />

• BX 601 rear quick-release M40141 (with 135 mm rear wheel only)<br />

• Axle reducers 12=>9 mm 996 942 01 (with 135 mm rear wheel only)<br />

• UST valves 995 282 01<br />

• M7 spoke wrench M40494 (with rear wheel)<br />

• <strong>Free</strong> play bearing adjustment wrench M40123 (with rear wheel)<br />

• User guide<br />

Replacing the front axle and bearings<br />

Rear wheel assembly diameter conversion<br />

Maintaining and replacing the free wheel mechanism<br />

Replacing the rear axle and bearings<br />

Replacing a spoke<br />

Replacing the front rim<br />

Replacing the rear rim<br />

See 2008 TM, page 24<br />

See page 25<br />

See page 29<br />

See page 30<br />

See page 41<br />

See pages 42/43<br />

See pages 44/45<br />

To consult this information quickly in a practical manner, refer to www.tech-mavic.com

24<br />

WHEEL MAINTENANCE<br />

WARRANTY REMINDER<br />

Before any repair of a Mavic wheel (or any other Mavic product), please note that it is guaranteed against manufacturing or material defects for a period of two<br />

years from the date of purchase by the original buyer.<br />

This means that:<br />

• During the warranty period and when it is clearly covered by the warranty (first contact your MSC), you must return the Mavic wheel (or any other Mavic product)<br />

directly to your MSC to benefit in full from the Mavic warranty.<br />

However, if you decide to repair the wheel (or any other Mavic product) yourself, your customer will lose the Mavic warranty.<br />

• For repairs after the warranty period has expired, we advise you to refer to the following pages before carrying out work on the Mavic wheel. When replacing<br />

the rim, please note the new serial number of the rim on the original warranty card and the date of replacement.<br />

Your customer’s new rim will only be covered by the Mavic warranty if this procedure is followed.<br />

REPAIRS<br />

The following pages will help you maintain the wheels in the 20<strong>09</strong> range and are laid out as follows:<br />

HUBS ........................................................................................................................................................................................................................... Page 25 - 30<br />

Hub assembly diameter conversion, front 15 mm and rear 12 mm ............................................................................................................................ Page 25<br />

Replacing bearings on the Crossmax SL Disc <strong>09</strong> Lefty wheel ..................................................................................................................................... Page 25<br />

Replacing the front axle and bearings on the Crossmax SLR Disc <strong>09</strong> and Crossmax ST Disc <strong>09</strong> Standard International model wheels ................ Page 26<br />

Replacing the front axle and bearings on the Crossmax SLR Disc <strong>09</strong> and Crossmax ST Disc <strong>09</strong> Center Lock model wheels ................................ Page 27<br />

Replacing the front axle and bearings on the Crossmax SX <strong>09</strong> and Crossline in Center Lock model wheels ............................................................ Page 28<br />

Maintaining and replacing the ITS4 free wheel mechanism ........................................................................................................................................ Page 29<br />

Replacing the rear axle and bearings on the ITS4 free wheel mechanism wheels ..................................................................................................... Page 30<br />

WHEEL BUILDING ......................................................................................................................................................................................................... Page 31 - 45<br />

Replacing the rear rim on the Ksyrium Elite <strong>09</strong> wheel ................................................................................................................................................. Page 31<br />

Replacing a spoke on the Cosmic Carbone SLR wheel ............................................................................................................................................... Page 32<br />

Replacing the front rim on the Cosmic Carbone SLR wheel ........................................................................................................................................ Page 33<br />

Replacing the rear rim on the Cosmic Carbone SLR wheel .................................................................................................................................... Page 34/35<br />

Removing and refitting the TraComp ring .................................................................................................................................................................... Page 36<br />

Replacing the front rim on the Crossmax SLR Disc <strong>09</strong>, Crossmax SLR Disc <strong>09</strong> 20 mm and Crossmax SLR Disc <strong>09</strong> Lefty wheels ........................ Page 37<br />

Replacing the front rim on the Crossride UB/Disc <strong>09</strong> and Crossride Disc <strong>09</strong> wheel .................................................................................................. Page 38<br />

Replacing the rear rim on the Crossride UB/<strong>disc</strong> <strong>09</strong> and Crossride Disc <strong>09</strong> wheel .................................................................................................... Page 39<br />

Replacing a spoke, front and rear rim on the Deetraks <strong>09</strong> wheels .............................................................................................................................. Page 40<br />

Replacing a spoke on the Deemax <strong>09</strong> and Deemax <strong>09</strong> SSC wheels .......................................................................................................................... Page 41<br />

Replacing the front rim on the Deemax <strong>09</strong> and Deemax <strong>09</strong> SSC wheels ............................................................................................................ Page 42 / 43<br />

Replacing the rear rim on the Deemax <strong>09</strong> and Deemax <strong>09</strong> SSC wheels ............................................................................................................. Page 44 / 45<br />