Premium G Install Manual - GeoSmart Energy

Premium G Install Manual - GeoSmart Energy

Premium G Install Manual - GeoSmart Energy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PREMIUM G SERIES INSTALLATION MANUAL<br />

Open Loop Ground Water Systems<br />

Typical open loop piping is shown below. Always maintain water<br />

pressure in the heat exchanger by placing water control valves at<br />

the outlet of the unit to prevent mineral precipitation. Use a closed,<br />

bladder-type expansion tank to minimize mineral formation due to<br />

air exposure. Insure proper water flow through the unit by checking<br />

pressure drop across the heat exchanger and comparing it to the<br />

figures in unit capacity data tables in the specification catalog. 1.5-<br />

2 GPM of flow per ton of cooling capacity is recommended in open<br />

loop applications. Due to only minor differences in flow rate from<br />

low to high, only one solenoid valve should be used. The valve<br />

should be sized for full flow.<br />

Discharge water from the unit is not contaminated in any manner<br />

and can be disposed of in various ways, depending on local codes,<br />

i.e. recharge well, storm sewer, drain field, adjacent stream or<br />

pond, etc. Most local codes forbid the use of sanitary sewer for<br />

disposal. Consult your local building and zoning departments to<br />

assure compliance in your area.<br />

NOTE: For open loop/groundwater systems or systems that do not<br />

contain an antifreeze solution, set SW2-Switch #2 to the “WELL”<br />

position (see DIP Switch Settings table in the Microprocessor<br />

Control section). Slow opening/closing solenoid valves (type V or<br />

VM) are recommended to eliminate water hammer.<br />

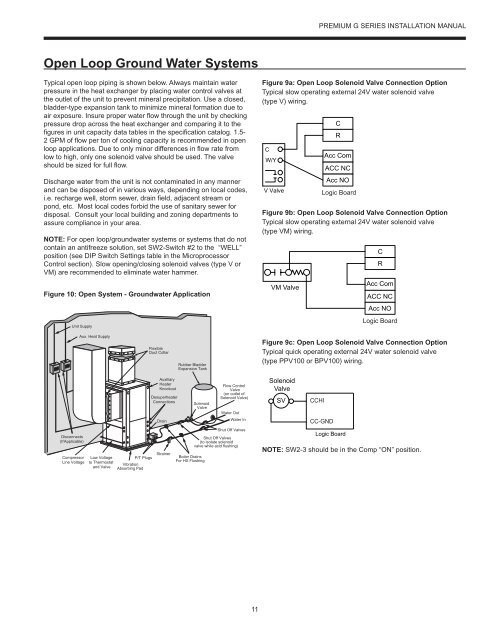

Figure 10: Open System - Groundwater Application<br />

Unit Supply<br />

Figure 9a: Open Loop Solenoid Valve Connection Option<br />

Typical slow operating external 24V water solenoid valve<br />

(type V) wiring.<br />

C<br />

W/Y<br />

V Valve<br />

Figure 9b: Open Loop Solenoid Valve Connection Option<br />

Typical slow operating external 24V water solenoid valve<br />

(type VM) wiring.<br />

VM Valve<br />

C<br />

R<br />

Acc Com<br />

ACC NC<br />

Acc NO<br />

Logic ABC Board<br />

C<br />

R<br />

Acc Com<br />

ACC NC<br />

Acc NO<br />

Logic<br />

ABC Board<br />

Board<br />

Aux. Heat Supply<br />

Flexible<br />

Duct Collar<br />

Rubber Bladder<br />

Expansion Tank<br />

Figure 9c: Open Loop Solenoid Valve Connection Option<br />

Typical quick operating external 24V water solenoid valve<br />

(type PPV100 or BPV100) wiring.<br />

Disconnects<br />

(IfApplicable)<br />

Compressor<br />

Line Voltage<br />

Low Voltage<br />

to Thermostat<br />

and Valve<br />

P/T Plugs<br />

Vibration<br />

Absorbing Pad<br />

Auxiliary<br />

Heater<br />

Knockout<br />

Desuperheater<br />

Connections<br />

Drain<br />

Strainer<br />

Solenoid<br />

Valve<br />

Boiler Drains<br />

For HX Flushing<br />

Flow Control<br />

Valve<br />

(on outlet of<br />

Solenoid Valve)<br />

Water Out<br />

Water In<br />

Shut Off Valves<br />

Shut Off Valves<br />

(to isolate solenoid<br />

valve while acid flushing)<br />

Solenoid<br />

Valve<br />

SV<br />

CCHI<br />

CC-GND<br />

Logic Board<br />

NOTE: SW2-3 should be in the Comp “ON” position.<br />

11