Linkage Sprayers Product Information (13176 Kb) - Fatcow

Linkage Sprayers Product Information (13176 Kb) - Fatcow

Linkage Sprayers Product Information (13176 Kb) - Fatcow

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Broadacre nozzles<br />

Nozzle Material and Wear<br />

Nozzle orifices are produced with different materials,<br />

the most durable of them being ceramic, followed by<br />

steel and various polymers. Nozzles with brass orifices<br />

are made from the least durable material.<br />

Worn or damaged nozzles will produce an uneven<br />

spray pattern with serious implications for efficacy.<br />

Worn or damaged nozzles in spray units without an<br />

automatic rate controller will increase the output, spoil<br />

calibration, and may create unnecessary extra costs due<br />

to over application.<br />

Most new sprayers have rate controllers that will<br />

compensate by measuring liquid flow and adjust<br />

accordingly. However, they will cause undersupply to<br />

the rest of the nozzles to adjust for the extra output of<br />

the worn nozzles. Again, this may result in an uneven<br />

spray pattern.<br />

Nozzles should be checked for wear at least once per<br />

season. As a rule of thumb, nozzles made from durable<br />

plastic will need replacement every two years, nozzles<br />

with steel orifices should be replaced every three years<br />

and nozzles with ceramic tips should be replaced<br />

every four to five years.<br />

These timeframes will decrease with heavy use,<br />

especially when spraying abrasive chemicals.<br />

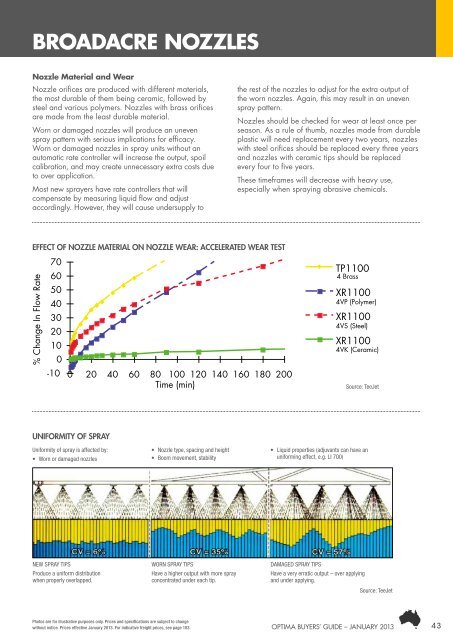

EFFECT OF NOZZLE MATERIAL ON NOZZLE WEAR: ACCELERATED WEAR TEST<br />

% Change In Flow Rate<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

-10<br />

0 20 40 60 80 100 120 140 160 180 200<br />

Time (min)<br />

TP1100<br />

4 Brass<br />

XR1100<br />

4VP (Polymer)<br />

XR1100<br />

4VS (Steel)<br />

XR1100<br />

4VK (Ceramic)<br />

Source: TeeJet<br />

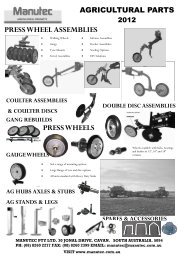

UNIFORMITY OF SPRAY<br />

Uniformity of spray is affected by:<br />

• Worn or damaged nozzles<br />

• Nozzle type, spacing and height<br />

• Boom movement, stability<br />

• Liquid properties (adjuvants can have an<br />

uniforming effect, e.g. LI 700)<br />

NEW SPRAY TIPS<br />

Produce a uniform distribution<br />

when properly overlapped.<br />

WORN SPRAY TIPS<br />

Have a higher output with more spray<br />

concentrated under each tip.<br />

DAMAGED SPRAY TIPS<br />

Have a very erratic output – over applying<br />

and under applying.<br />

Source: TeeJet<br />

Photos are for illustrative purposes only. Prices and specifications are subject to change<br />

without notice. Prices effective January 2013. For indicative freight prices, see page 103. 43<br />

Optima BUYERS’ GUIDE – JANUARY 2013