Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

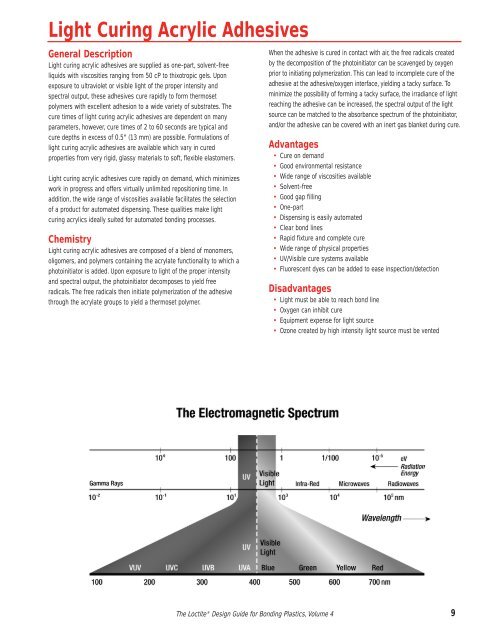

Light Curing Acrylic AdhesivesGeneral DescriptionLight curing acrylic adhesives are supplied as one-part, solvent-freeliquids with viscosities ranging from 50 cP to thixotropic gels. Uponexposure to ultraviolet or visible light of the proper intensity andspectral output, these adhesives cure rapidly to form thermosetpolymers with excellent adhesion to a wide variety of substrates. Thecure times of light curing acrylic adhesives are dependent on manyparameters, however, cure times of 2 to 60 seconds are typical andcure depths in excess of 0.5" (13 mm) are possible. Formulations oflight curing acrylic adhesives are available which vary in curedproperties from very rigid, glassy materials to soft, flexible elastomers.Light curing acrylic adhesives cure rapidly on demand, which minimizeswork in progress and offers virtually unlimited repositioning time. Inaddition, the wide range of viscosities available facilitates the selectionof a product for automated dispensing. These qualities make lightcuring acrylics ideally suited for automated bonding processes.ChemistryLight curing acrylic adhesives are composed of a blend of monomers,oligomers, and polymers containing the acrylate functionality to which a<strong>ph</strong>otoinitiator is added. Upon exposure to light of the proper intensityand spectral output, the <strong>ph</strong>otoinitiator decomposes to yield freeradicals. The free radicals then initiate polymerization of the adhesivethrough the acrylate groups to yield a thermoset polymer.When the adhesive is cured in contact with air, the free radicals createdby the decomposition of the <strong>ph</strong>otoinitiator can be scavenged by oxygenprior to initiating polymerization. This can lead to incomplete cure of theadhesive at the adhesive/oxygen interface, yielding a tacky surface. Tominimize the possibility of forming a tacky surface, the irradiance of lightreaching the adhesive can be increased, the spectral output of the lightsource can be matched to the absorbance spectrum of the <strong>ph</strong>otoinitiator,and/or the adhesive can be covered with an inert gas blanket during cure.Advantages• Cure on demand• Good environmental resistance• Wide range of viscosities available• Solvent-free• Good gap filling• One-part• Dispensing is easily automated• Clear bond lines• Rapid fixture and complete cure• Wide range of <strong>ph</strong>ysical properties• UV/Visible cure systems available• Fluorescent dyes can be added to ease inspection/detectionDisadvantages• Light must be able to reach bond line• Oxygen can inhibit cure• Equipment expense for light source• Ozone created by high intensity light source must be ventedThe <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 9