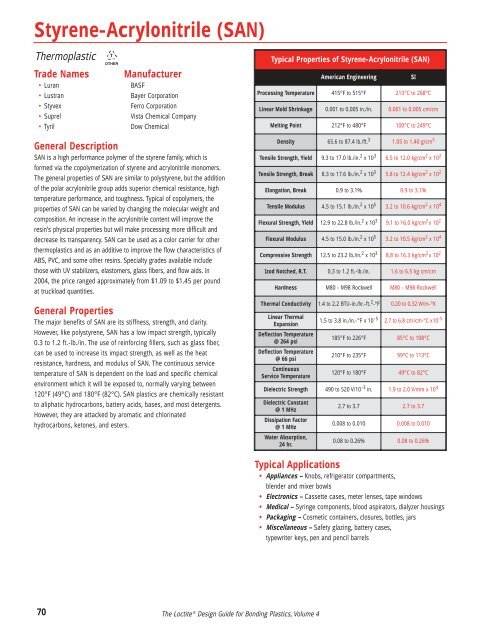

Styrene-Acrylonitrile (SAN)ThermoplasticTrade Names Manufacturer• LuranBASF• LustranBayer Corporation• StyvexFerro Corporation• SuprelVista Chemical Company• TyrilDow ChemicalTypical Properties of Styrene-Acrylonitrile (SAN)American EngineeringSIProcessing Temperature 415°F to 515°F 213°C to 268°CLinear Mold Shrinkage 0.001 to 0.005 in./in. 0.001 to 0.005 cm/cmMelting Point 212°F to 480°F 100°C to 249°CGeneral DescriptionSAN is a high performance polymer of the styrene family, which isformed via the copolymerization of styrene and acrylonitrile monomers.The general properties of SAN are similar to polystyrene, but the additionof the polar acrylonitrile group adds superior chemical resistance, hightemperature performance, and toughness. Typical of copolymers, theproperties of SAN can be varied by changing the molecular weight andcomposition. An increase in the acrylonitrile content will improve theresin’s <strong>ph</strong>ysical properties but will make processing more difficult anddecrease its transparency. SAN can be used as a color carrier for otherthermoplastics and as an additive to improve the flow characteristics ofABS, PVC, and some other resins. Specialty grades available includethose with UV stabilizers, elastomers, glass fibers, and flow aids. In2004, the price ranged approximately from $1.09 to $1.45 per poundat truckload quantities.General PropertiesThe major benefits of SAN are its stiffness, strength, and clarity.However, like polystyrene, SAN has a low impact strength, typically0.3 to 1.2 ft.-lb./in. The use of reinforcing fillers, such as glass fiber,can be used to increase its impact strength, as well as the heatresistance, hardness, and modulus of SAN. The continuous servicetemperature of SAN is dependent on the load and specific chemicalenvironment which it will be exposed to, normally varying between120°F (49°C) and 180°F (82°C). SAN plastics are chemically resistantto ali<strong>ph</strong>atic hydrocarbons, battery acids, bases, and most detergents.However, they are attacked by aromatic and chlorinatedhydrocarbons, ketones, and esters.Density 65.6 to 87.4 lb./ft. 3 1.05 to 1.40 g/cm 3Tensile Strength, Yield 9.3 to 17.0 lb./in. 2 x 10 3 6.5 to 12.0 kg/cm 2 x 10 2Tensile Strength, Break 8.3 to 17.6 lb./in. 2 x 10 3 5.8 to 12.4 kg/cm 2 x 10 2Elongation, Break 0.9 to 3.1% 0.9 to 3.1%Tensile Modulus 4.5 to 15.1 lb./in. 2 x 10 5 3.2 to 10.6 kg/cm 2 x 10 4Flexural Strength, Yield 12.9 to 22.8 lb./in. 2 x 10 3 9.1 to 16.0 kg/cm 2 x 10 2Flexural Modulus 4.5 to 15.0 lb./in. 2 x 10 5 3.2 to 10.5 kg/cm 2 x 10 4Compressive Strength 12.5 to 23.2 lb./in. 2 x 10 3 8.8 to 16.3 kg/cm 2 x 10 2Izod Notched, R.T. 0.3 to 1.2 ft.-lb./in. 1.6 to 6.5 kg cm/cmHardness M80 - M98 Rockwell M80 - M98 RockwellThermal Conductivity 1.4 to 2.2 BTU-in./hr.-ft. 2 -°F 0.20 to 0.32 W/m-°KLinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature1.5 to 3.8 in./in.-°F x 10 -5 2.7 to 6.8 cm/cm-°C x10 -5185°F to 226°F 85°C to 108°C210°F to 235°F 99°C to 113°C120°F to 180°F 49°C to 82°CDielectric Strength 490 to 520 V/10 -3 in. 1.9 to 2.0 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.2.7 to 3.7 2.7 to 3.70.008 to 0.010 0.008 to 0.0100.08 to 0.26% 0.08 to 0.26%Typical Applications• Appliances – Knobs, refrigerator compartments,blender and mixer bowls• Electronics – Cassette cases, meter lenses, tape windows• Medical – Syringe components, blood aspirators, dialyzer housings• Packaging – Cosmetic containers, closures, bottles, jars• Miscellaneous – Safety glazing, battery cases,typewriter keys, pen and pencil barrels70The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4

ADHESIVE SHEAR STRENGTH(psi)(MPa)Styrene-AcrylonitrileUNFILLED RESIN3 rmsROUGHENED18 rmsUV STABILIZER0.31% Tinuvin 7700.31% Tinuvin 328FLAME RETARDANT4% Saytex HBCD-SF1% Antimony OxideIMPACT MODIFIER29% Paraloid EXL3330LUBRICANT0.1% Calcium Stearate24-46INTERNAL MOLDRELEASE5% Mold Wiz INT-33PAGLASS FILLER17% Glass Type 3540COLORANT1% OmniColor FuschiaLustran 31 Natural courtesy of Bayer Corporation Lustran 31 produced by MonsantoANTISTATIC3% Armostat 550<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone5003.5>850 >2050 500>5.9 >14.1 3.5>3800 >3800 >3800 1850>26.2 >26.2 >26.2 12.84503.111507.94503.1>3650 >3650 >5950 1550>25.2 >25.2 >41.0 10.78005.5280019.34503.1>3350 >23.1 150010.414009.7>2300 >15.9 2501.74002.82501.73502.48505.94503.11000.7500.3500.3>1300 >9.0 5503.84002.82001.48005.5>2900 2800>20.0 19.3>1200 800>8.3 5.510006.95003.57505.25003.55003.5>1850 >12.8 >3800 >3800 >3800 >3800 >3800 >3800 >26.2 >26.2 >26.2 >26.2 >26.2 >26.2 >1000 >1450 >750 450>6.9 >10.0 >5.2 3.1>2900 2800>19.3 19.34503.114009.74503.1>3650 >3650 >3650 >4550 >3650 >3650 >25.2 >25.2 >25.2 >31.4 >25.2 >25.2 >1100 800>7.6 5.5280019.38005.5175012.18005.5280019.3>900 800>6.2 5.5280019.3>3000 >20.7 Adhesive Performance<strong>Loctite</strong> ® 401 Prism ® and 414 Super Bonder ® Instant Adhesives, and <strong>Loctite</strong> ® 4305 Flashcure ® LightCure Adhesive created bonds stronger than the SAN substrate for all the formulations which wereevaluated, with the exception of the formulation containing the flame retardant additive. <strong>Loctite</strong> ® 3105 Light Cure Adhesive and <strong>Loctite</strong> ® 3030 Adhesive achieved the second highest bond strengths. The overallbondability of all the tested adhesives on various grades of SAN is very good with the exceptions being<strong>Loctite</strong> ® 3651 and 7804 Hysol ® Hot Melt Adhesives.Surface TreatmentsSurface roughening caused either no effect or a statistically significant increase in the bond strengthsachieved on SAN. The use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ® 401 Prism ®Instant Adhesive, or <strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ® 7701 Prism ®Primer, caused a statistically significant decrease in the bond strengths achieved on SAN for all theformulations which were evaluated.Other Important Information• SAN is compatible with acrylic adhesives, but can be attacked by their activators before theadhesive has cured. Any excess activator should be removed from the surface immediately.• SAN is incompatible with anaerobic adhesives.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.NOTES: The force applied to the tests specimens exceededthe strength of the material resulting in substrate failurebefore the actual bond strength achieved by theadhesive could be determined.The addition of the indicated additive (or surfaceroughening) caused a statistically significant decrease inthe bond strength within 95% confidence limits.The addition of the indicated additive (or surfaceroughening) caused a statistically significant increase inthe bond strength within 95% confidence limits.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 71