Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

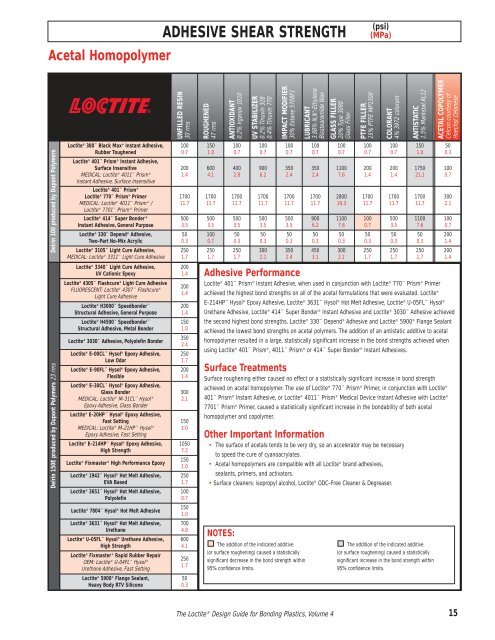

ADHESIVE SHEAR STRENGTH(psi)(MPa)Acetal HomopolymerUNFILLED RESIN30 rmsROUGHENED47 rmsANTIOXIDANT0.2% Irganox 1010UV STABILIZER0.2% Tinuvin 3280.4% Tinuvin 770IMPACT MODIFIER30% Estane 5708F1LUBRICANT3.88% N,N'-EthyleneBisstearamide WaxGLASS FILLER20% Type 3090Glass FillerPTFE FILLER15% PTFE MP1300COLORANT4% 3972 colorantDelrin 100 produced by Dupont PolymersANTISTATIC1.5% Markstat AL12ACETAL COPOLYMERCelcon courtesy ofHoechst Celanese<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive1000.72001.4170011.75003.5500.32501.71501.06004.1170011.75003.51000.72501.71000.74002.8170011.75003.5500.32501.71000.79006.2170011.75003.5500.33002.11000.73502.4170011.75003.5500.33502.41000.73502.4170011.79006.2500.34503.11000.711007.6280019.311007.6500.33002.11000.72001.4170011.71000.7500.32501.71000.72001.4170011.75003.5500.32501.71501.0175021.1170011.711007.6500.32501.7500.31000.73002.11000.72001.42001.4Delrin 150E produced by Dupont Polymers 23 rms<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin2001.42001.42001.41501.03502.42501.72001.43002.11501.010507.21501.02501.71000.7Adhesive Performance<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive, when used in conjunction with <strong>Loctite</strong> ® 770 Prism ® Primerachieved the highest bond strengths on all of the acetal formulations that were evaluated. <strong>Loctite</strong> ®E-214HP Hysol ® Epoxy Adhesive, <strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive, <strong>Loctite</strong> ® U-05FL Hysol ®Urethane Adhesive, <strong>Loctite</strong> ® 414 Super Bonder ® Instant Adhesive and <strong>Loctite</strong> ® 3030 Adhesive achievedthe second highest bond strengths. <strong>Loctite</strong> ® 330 Depend ® Adhesive and <strong>Loctite</strong> ® 5900 ® Flange Sealantachieved the lowest bond strengths on acetal polymers. The addition of an antistatic additive to acetalhomopolymer resulted in a large, statistically significant increase in the bond strengths achieved whenusing <strong>Loctite</strong> ® 401 Prism ® , 4011 Prism ® or 414 Super Bonder ® Instant Adhesives.Surface TreatmentsSurface roughening either caused no effect or a statistically significant increase in bond strengthachieved on acetal homopolymer. The use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ®401 Prism ® Instant Adhesive, or <strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ®7701 Prism ® Primer, caused a statistically significant increase in the bondability of both acetalhomopolymer and copolymer.Other Important Information• The surface of acetals tends to be very dry, so an accelerator may be necessaryto speed the cure of cyanoacrylates.• Acetal homopolymers are compatible with all <strong>Loctite</strong> ® brand adhesives,sealants, primers, and activators.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive1501.0<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting7004.86004.12501.7NOTES:The addition of the indicated additive(or surface roughening) caused a statisticallysignificant decrease in the bond strength within95% confidence limits.NOTES:The addition of the indicated additive(or surface roughening) caused a statisticallysignificant increase in the bond strength within95% confidence limits.<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone500.3The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 15