Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

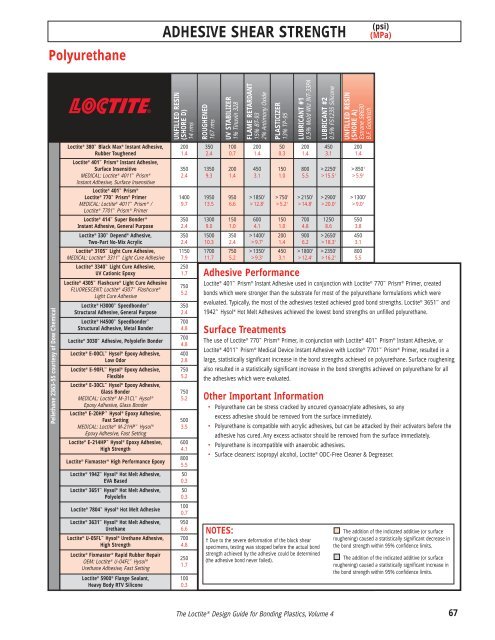

ADHESIVE SHEAR STRENGTH(psi)(MPa)PolyurethaneUNFILLED RESIN(SHORE D)14 rmsROUGHENED167 rmsUV STABILIZER1% Tinuvin 328FLAME RETARDANT15% BT-932% Antimony OxidePLASTICIZER13% TP-95LUBRICANT #10.5% Mold Wiz INT-33PALUBRICANT #20.5% FS1235 SiliconeUNFILLED RESIN(SHORE A)Estrane 58630B.F. Goodrich<strong>Loctite</strong> ® 380 Black Max ® Instant Adhesive,Rubber Toughened2001.43502.41000.72001.4500.32001.44503.12001.4<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive,Surface InsensitiveMEDICAL: <strong>Loctite</strong> ® 4011 Prism ®Instant Adhesive, Surface Insensitive3502.413509.32001.44503.11501.08005.5>2250 † >850 †>15.5 † >5.9 †<strong>Loctite</strong> ® 401 Prism ®<strong>Loctite</strong> ® 770 Prism ® PrimerMEDICAL: <strong>Loctite</strong> ® 4011 Prism ® /<strong>Loctite</strong> ® 7701 Prism ® Primer14009.7195013.59506.6>1850 † >750 † >2150 † >2900 † >1300 †>12.8 † >5.2 † >14.8 † >20.0 † >9.0 †<strong>Loctite</strong> ® 414 Super Bonder ®Instant Adhesive, General Purpose3502.413009.01501.06004.11501.07004.812508.65503.8<strong>Loctite</strong> ® 330 Depend ® Adhesive,Two-Part No-Mix Acrylic3502.4150010.33502.4>1400 †>9.7 † 2001.49006.2>2650 † 450>18.3 † 3.1<strong>Loctite</strong> ® 3105 Light Cure Adhesive,MEDICAL: <strong>Loctite</strong> ® 3311 Light Cure Adhesive11507.9170011.77505.2>1350 †>9.3 † 4503.1>1800 † >2350 † 800>12.4 † >16.2 † 5.5Pellethane 2363-55 courtesy of Dow Chemical<strong>Loctite</strong> ® 3340 Light Cure Adhesive,UV Cationic Epoxy<strong>Loctite</strong> ® 4305 Flashcure ® Light Cure AdhesiveFLUORESCENT: <strong>Loctite</strong> ® 4307 Flashcure ®Light Cure Adhesive<strong>Loctite</strong> ® H3000 Speedbonder Structural Adhesive, General Purpose<strong>Loctite</strong> ® H4500 Speedbonder Structural Adhesive, Metal Bonder<strong>Loctite</strong> ® 3030 Adhesive, Polyolefin Bonder<strong>Loctite</strong> ® E-00CL Hysol ® Epoxy Adhesive,Low Odor<strong>Loctite</strong> ® E-90FL Hysol ® Epoxy Adhesive,Flexible<strong>Loctite</strong> ® E-30CL Hysol ® Epoxy Adhesive,Glass BonderMEDICAL: <strong>Loctite</strong> ® M-31CL Hysol ®Epoxy Adhesive, Glass Bonder<strong>Loctite</strong> ® E-20HP Hysol ® Epoxy Adhesive,Fast SettingMEDICAL: <strong>Loctite</strong> ® M-21HP Hysol ®Epoxy Adhesive, Fast Setting<strong>Loctite</strong> ® E-214HP Hysol ® Epoxy Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® High Performance Epoxy2501.77505.23502.47004.87004.84002.87505.27505.25003.56004.18005.5Adhesive Performance<strong>Loctite</strong> ® 401 Prism ® Instant Adhesive used in conjunction with <strong>Loctite</strong> ® 770 Prism ® Primer, createdbonds which were stronger than the substrate for most of the polyurethane formulations which wereevaluated. Typically, the most of the adhesives tested achieved good bond strengths. <strong>Loctite</strong> ® 3651 and1942 Hysol ® Hot Melt Adhesives achieved the lowest bond strengths on unfilled polyurethane.Surface TreatmentsThe use of <strong>Loctite</strong> ® 770 Prism ® Primer, in conjunction with <strong>Loctite</strong> ® 401 Prism ® Instant Adhesive, or<strong>Loctite</strong> ® 4011 Prism ® Medical Device Instant Adhesive with <strong>Loctite</strong> ® 7701 Prism ® Primer, resulted in alarge, statistically significant increase in the bond strengths achieved on polyurethane. Surface rougheningalso resulted in a statistically significant increase in the bond strengths achieved on polyurethane for allthe adhesives which were evaluated.Other Important Information• Polyurethane can be stress cracked by uncured cyanoacrylate adhesives, so anyexcess adhesive should be removed from the surface immediately.• Polyurethane is compatible with acrylic adhesives, but can be attacked by their activators before theadhesive has cured. Any excess activator should be removed from the surface immediately.• Polyurethane is incompatible with anaerobic adhesives.• Surface cleaners: isopropyl alcohol, <strong>Loctite</strong> ® ODC-Free Cleaner & Degreaser.<strong>Loctite</strong> ® 1942 Hysol ® Hot Melt Adhesive,EVA Based500.3<strong>Loctite</strong> ® 3651 Hysol ® Hot Melt Adhesive,Polyolefin500.3<strong>Loctite</strong> ® 7804 Hysol ® Hot Melt Adhesive1000.7<strong>Loctite</strong> ® 3631 Hysol ® Hot Melt Adhesive,Urethane<strong>Loctite</strong> ® U-05FL Hysol ® Urethane Adhesive,High Strength<strong>Loctite</strong> ® Fixmaster ® Rapid Rubber RepairOEM: <strong>Loctite</strong> ® U-04FL Hysol ®Urethane Adhesive, Fast Setting<strong>Loctite</strong> ® 5900 ® Flange Sealant,Heavy Body RTV Silicone9506.67004.82501.71000.3NOTES:† Due to the severe deformation of the block shearspecimens, testing was stopped before the actual bondstrength achieved by the adhesive could be determined(the adhesive bond never failed).The addition of the indicated additive (or surfaceroughening) caused a statistically significant decrease inthe bond strength within 95% confidence limits.The addition of the indicated additive (or surfaceroughening) caused a statistically significant increase inthe bond strength within 95% confidence limits.The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4 67