Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

Volume 4 - Loctite.ph

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

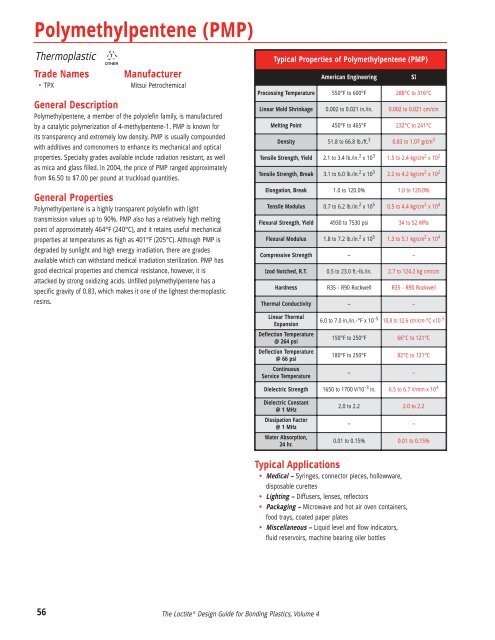

Polymethylpentene (PMP)ThermoplasticTrade Names• TPXManufacturerMitsui PetrochemicalGeneral DescriptionPolymethylpentene, a member of the polyolefin family, is manufacturedby a catalytic polymerization of 4-methylpentene-1. PMP is known forits transparency and extremely low density. PMP is usually compoundedwith additives and comonomers to enhance its mechanical and opticalproperties. Specialty grades available include radiation resistant, as wellas mica and glass filled. In 2004, the price of PMP ranged approximatelyfrom $6.50 to $7.00 per pound at truckload quantities.General PropertiesPolymethylpentene is a highly transparent polyolefin with lighttransmission values up to 90%. PMP also has a relatively high meltingpoint of approximately 464°F (240°C), and it retains useful mechanicalproperties at temperatures as high as 401°F (205°C). Although PMP isdegraded by sunlight and high energy irradiation, there are gradesavailable which can withstand medical irradiation sterilization. PMP hasgood electrical properties and chemical resistance, however, it isattacked by strong oxidizing acids. Unfilled polymethylpentene has aspecific gravity of 0.83, which makes it one of the lightest thermoplasticresins.Typical Properties of Polymethylpentene (PMP)American EngineeringProcessing Temperature 550°F to 600°F 288°C to 316°CLinear Mold Shrinkage 0.002 to 0.021 in./in. 0.002 to 0.021 cm/cmMelting Point 450°F to 465°F 232°C to 241°CDensity 51.8 to 66.8 lb./ft. 3 0.83 to 1.07 g/cm 3Tensile Strength, Yield 2.1 to 3.4 lb./in. 2 x 10 3 1.5 to 2.4 kg/cm 2 x 10 2Tensile Strength, Break 3.1 to 6.0 lb./in. 2 x 10 3 2.2 to 4.2 kg/cm 2 x 10 2Elongation, Break 1.0 to 120.0% 1.0 to 120.0%Tensile Modulus 0.7 to 6.2 lb./in. 2 x 10 5 0.5 to 4.4 kg/cm 2 x 10 4Flexural Strength, Yield 4930 to 7530 psi 34 to 52 MPaFlexural Modulus 1.8 to 7.2 lb./in. 2 x 10 5 1.3 to 5.1 kg/cm 2 x 10 4Compressive Strength – –Izod Notched, R.T. 0.5 to 23.0 ft.-lb./in. 2.7 to 124.2 kg cm/cmHardness R35 - R90 Rockwell R35 - R90 RockwellThermal Conductivity – –SILinear ThermalExpansionDeflection Temperature@ 264 psiDeflection Temperature@ 66 psiContinuousService Temperature6.0 to 7.0 in./in.-°F x 10 -5 10.8 to 12.6 cm/cm-°C x10 -5150°F to 250°F 66°C to 121°C180°F to 250°F 82°C to 121°C– –Dielectric Strength 1650 to 1700 V/10 -3 in. 6.5 to 6.7 V/mm x 10 4Dielectric Constant@ 1 MHzDissipation Factor@ 1 MHzWater Absorption,24 hr.2.0 to 2.2 2.0 to 2.2– –0.01 to 0.15% 0.01 to 0.15%Typical Applications• Medical – Syringes, connector pieces, hollowware,disposable curettes• Lighting – Diffusers, lenses, reflectors• Packaging – Microwave and hot air oven containers,food trays, coated paper plates• Miscellaneous – Liquid level and flow indicators,fluid reservoirs, machine bearing oiler bottles56The <strong>Loctite</strong> ® Design Guide for Bonding Plastics, <strong>Volume</strong> 4