Screen E-Book (.PDF) - MacDermid Autotype

Screen E-Book (.PDF) - MacDermid Autotype

Screen E-Book (.PDF) - MacDermid Autotype

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

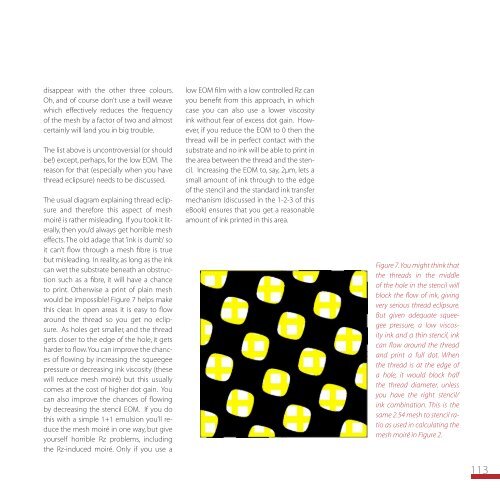

disappear with the other three colours.Oh, and of course don’t use a twill weavewhich effectively reduces the frequencyof the mesh by a factor of two and almostcertainly will land you in big trouble.The list above is uncontroversial (or shouldbe!) except, perhaps, for the low EOM. Thereason for that (especially when you havethread eclipsure) needs to be discussed.The usual diagram explaining thread eclipsureand therefore this aspect of meshmoiré is rather misleading. If you took it literally,then you’d always get horrible mesheffects. The old adage that ‘ink is dumb’ soit can’t flow through a mesh fibre is truebut misleading. In reality, as long as the inkcan wet the substrate beneath an obstructionsuch as a fibre, it will have a chanceto print. Otherwise a print of plain meshwould be impossible! Figure 7 helps makethis clear. In open areas it is easy to flowaround the thread so you get no eclipsure.As holes get smaller, and the threadgets closer to the edge of the hole, it getsharder to flow. You can improve the chancesof flowing by increasing the squeegeepressure or decreasing ink viscosity (thesewill reduce mesh moiré) but this usuallycomes at the cost of higher dot gain. Youcan also improve the chances of flowingby decreasing the stencil EOM. If you dothis with a simple 1+1 emulsion you’ll reducethe mesh moiré in one way, but giveyourself horrible Rz problems, includingthe Rz-induced moiré. Only if you use alow EOM film with a low controlled Rz canyou benefit from this approach, in whichcase you can also use a lower viscosityink without fear of excess dot gain. However,if you reduce the EOM to 0 then thethread will be in perfect contact with thesubstrate and no ink will be able to print inthe area between the thread and the stencil.Increasing the EOM to, say, 2μm, lets asmall amount of ink through to the edgeof the stencil and the standard ink transfermechanism (discussed in the 1-2-3 of thise<strong>Book</strong>) ensures that you get a reasonableamount of ink printed in this area.Figure 7. You might think thatthe threads in the middleof the hole in the stencil willblock the flow of ink, givingvery serious thread eclipsure.But given adequate squeegeepressure, a low viscosityink and a thin stencil, inkcan flow around the threadand print a full dot. Whenthe thread is at the edge ofa hole, it would block halfthe thread diameter, unlessyou have the right stencil/ink combination. This is thesame 2.54 mesh to stencil ratioas used in calculating themesh moiré in Figure 2.113