Screen E-Book (.PDF) - MacDermid Autotype

Screen E-Book (.PDF) - MacDermid Autotype

Screen E-Book (.PDF) - MacDermid Autotype

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

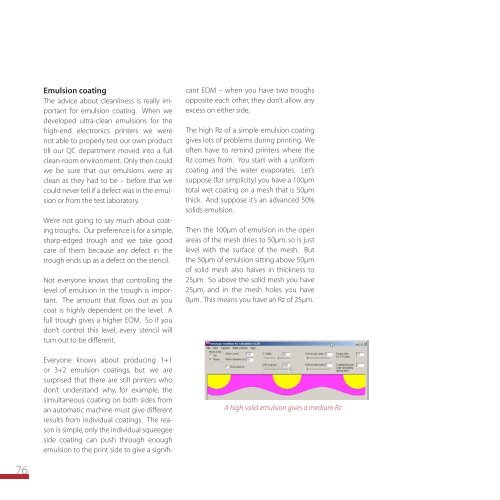

Emulsion coatingThe advice about cleanliness is really importantfor emulsion coating. When wedeveloped ultra-clean emulsions for thehigh-end electronics printers we werenot able to properly test our own producttill our QC department moved into a fullclean-room environment. Only then couldwe be sure that our emulsions were asclean as they had to be – before that wecould never tell if a defect was in the emulsionor from the test laboratory.We’re not going to say much about coatingtroughs. Our preference is for a simple,sharp-edged trough and we take goodcare of them because any defect in thetrough ends up as a defect on the stencil.Not everyone knows that controlling thelevel of emulsion in the trough is important.The amount that flows out as youcoat is highly dependent on the level. Afull trough gives a higher EOM. So if youdon’t control this level, every stencil willturn out to be different.Everyone knows about producing 1+1or 3+2 emulsion coatings, but we aresurprised that there are still printers whodon’t understand why, for example, thesimultaneous coating on both sides froman automatic machine must give differentresults from individual coatings. The reasonis simple, only the individual squeegeeside coating can push through enoughemulsion to the print side to give a significantEOM – when you have two troughsopposite each other, they don’t allow anyexcess on either side.The high Rz of a simple emulsion coatinggives lots of problems during printing. Weoften have to remind printers where theRz comes from. You start with a uniformcoating and the water evaporates. Let’ssuppose (for simplicity) you have a 100µmtotal wet coating on a mesh that is 50µmthick. And suppose it’s an advanced 50%solids emulsion.Then the 100µm of emulsion in the openareas of the mesh dries to 50µm, so is justlevel with the surface of the mesh. Butthe 50µm of emulsion sitting above 50µmof solid mesh also halves in thickness to25µm. So above the solid mesh you have25µm, and in the mesh holes you have0µm. This means you have an Rz of 25µm.A high solid emulsion gives a medium Rz76