You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> Cantacuzene Period (1952–1965)<br />

discharge of effluent into the sea at the river mouth commenced on<br />

11 August and the foam was of some concern to the local authorities�<br />

By this time, 27 white South Africans had been employed – there<br />

were language problems�<br />

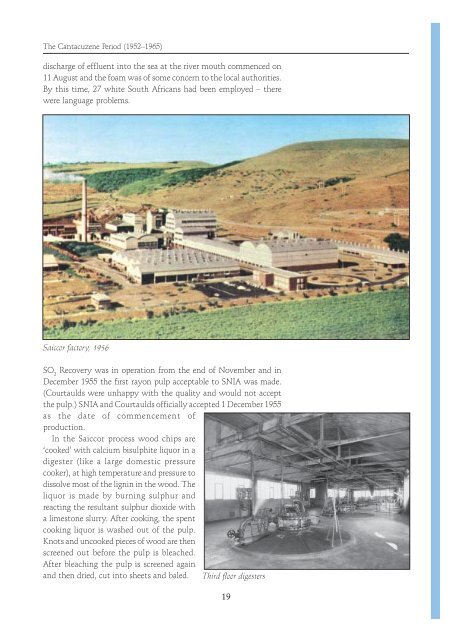

<strong>Saiccor</strong> factory, 1956<br />

SO Recovery was in operation from the end of November and in<br />

2<br />

December 1955 the first rayon pulp acceptable to SNIA was made�<br />

(Courtaulds were unhappy with the quality and would not accept<br />

the pulp�) SNIA and Courtaulds officially accepted 1 December 1955<br />

as the date of commencement of<br />

production�<br />

In the <strong>Saiccor</strong> process wood chips are<br />

‘cooked’ with calcium bisulphite liquor in a<br />

digester (like a large domestic pressure<br />

cooker), at high temperature and pressure to<br />

dissolve most of the lignin in the wood� <strong>The</strong><br />

liquor is made by burning sulphur and<br />

reacting the resultant sulphur dioxide with<br />

a limestone slurry� After cooking, the spent<br />

cooking liquor is washed out of the pulp�<br />

Knots and uncooked pieces of wood are then<br />

screened out before the pulp is bleached�<br />

After bleaching the pulp is screened again<br />

and then dried, cut into sheets and baled� Third floor digesters<br />

19