Environmental Declaration 2011 - Sappi

Environmental Declaration 2011 - Sappi

Environmental Declaration 2011 - Sappi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

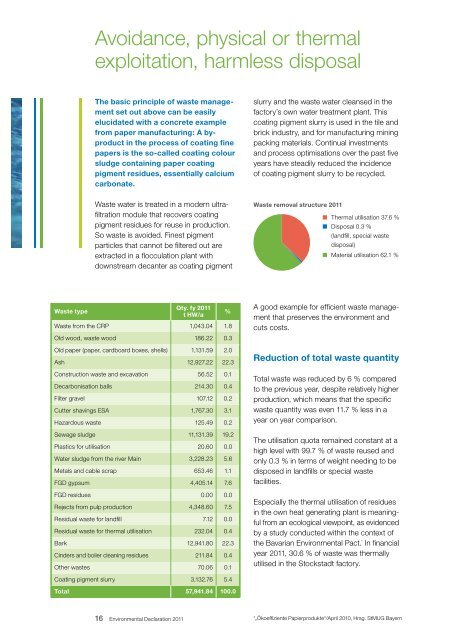

Waste type<br />

Avoidance, physical or thermal<br />

exploitation, harmless disposal<br />

The basic principle of waste management<br />

set out above can be easily<br />

elucidated with a concrete example<br />

from paper manufacturing: A by-<br />

product in the process of coating fine<br />

papers is the so-called coating colour<br />

sludge containing paper coating<br />

pigment residues, essentially calcium<br />

carbonate.<br />

Waste water is treated in a modern ultrafiltration<br />

module that recovers coating<br />

pigment residues for reuse in production.<br />

So waste is avoided. Finest pigment<br />

particles that cannot be filtered out are<br />

extracted in a flocculation plant with<br />

downstream decanter as coating pigment<br />

Qty. fy <strong>2011</strong><br />

t HW/a<br />

Waste from the CRP 1,043.04 1.8<br />

Old wood, waste wood 186.22 0.3<br />

Old paper (paper, cardboard boxes, shells) 1,131.59 2.0<br />

Ash 12,927.22 22.3<br />

Construction waste and excavation 56.52 0.1<br />

Decarbonisation balls 214.30 0.4<br />

Filter gravel 107.12 0.2<br />

Cutter shavings ESA 1,767.30 3.1<br />

Hazardous waste 125.49 0.2<br />

Sewage sludge 11,131.39 19.2<br />

Plastics for utilisation 20.60 0.0<br />

Water sludge from the river Main 3,228.23 5.6<br />

Metals and cable scrap 653.46 1.1<br />

FGD gypsum 4,405.14 7.6<br />

FGD residues 0.00 0.0<br />

Rejects from pulp production 4,348.60 7.5<br />

Residual waste for landfill 7.12 0.0<br />

Residual waste for thermal utilisation 232.04 0.4<br />

Bark 12,941.80 22.3<br />

Cinders and boiler cleaning residues 211.84 0.4<br />

Other wastes 70.06 0.1<br />

Coating pigment slurry 3,132.76 5.4<br />

Total 57,941.84 100.0<br />

16 <strong>Environmental</strong> <strong>Declaration</strong> <strong>2011</strong><br />

%<br />

slurry and the waste water cleansed in the<br />

factory’s own water treatment plant. This<br />

coating pigment slurry is used in the tile and<br />

brick industry, and for manufacturing mining<br />

packing materials. Continual investments<br />

and process optimisations over the past five<br />

years have steadily reduced the incidence<br />

of coating pigment slurry to be recycled.<br />

Waste removal structure <strong>2011</strong><br />

n Thermal utilisation 37.6 %<br />

n Disposal 0.3 %<br />

(landfill, special waste<br />

disposal)<br />

n Material utilisation 62.1 %<br />

A good example for efficient waste management<br />

that preserves the environment and<br />

cuts costs.<br />

Reduction of total waste quantity<br />

Total waste was reduced by 6 % compared<br />

to the previous year, despite relatively higher<br />

production, which means that the specific<br />

waste quantity was even 11.7 % less in a<br />

year on year comparison.<br />

The utilisation quota remained constant at a<br />

high level with 99.7 % of waste reused and<br />

only 0.3 % in terms of weight needing to be<br />

disposed in landfills or special waste<br />

facilities.<br />

Especially the thermal utilisation of residues<br />

in the own heat generating plant is meaning<br />

ful from an ecological viewpoint, as evidenced<br />

by a study conducted within the context of<br />

the Bavarian <strong>Environmental</strong> Pact. * In financial<br />

year <strong>2011</strong>, 30.6 % of waste was thermally<br />

utilised in the Stockstadt factory.<br />

*„Ökoeffiziente Papierprodukte“/April 2010, Hrsg. StMUG Bayern