Download the Rubbery Owen Maintenance Manual in PDF Format

Download the Rubbery Owen Maintenance Manual in PDF Format

Download the Rubbery Owen Maintenance Manual in PDF Format

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

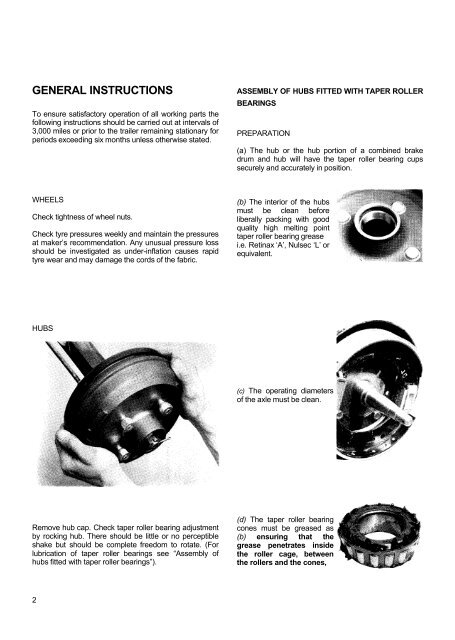

GENERAL INSTRUCTIONSTo ensure satisfactory operation of all work<strong>in</strong>g parts <strong>the</strong>follow<strong>in</strong>g <strong>in</strong>structions should be carried out at <strong>in</strong>tervals of3,000 miles or prior to <strong>the</strong> trailer rema<strong>in</strong><strong>in</strong>g stationary forperiods exceed<strong>in</strong>g six months unless o<strong>the</strong>rwise stated.ASSEMBLY OF HUBS FITTED WITH TAPER ROLLERBEARINGSPREPARATION(a) The hub or <strong>the</strong> hub portion of a comb<strong>in</strong>ed brakedrum and hub will have <strong>the</strong> taper roller bear<strong>in</strong>g cupssecurely and accurately <strong>in</strong> position.WHEELSCheck tightness of wheel nuts.Check tyre pressures weekly and ma<strong>in</strong>ta<strong>in</strong> <strong>the</strong> pressuresat maker’s recommendation. Any unusual pressure lossshould be <strong>in</strong>vestigated as under-<strong>in</strong>flation causes rapidtyre wear and may damage <strong>the</strong> cords of <strong>the</strong> fabric.(b) The <strong>in</strong>terior of <strong>the</strong> hubsmust be clean beforeliberally pack<strong>in</strong>g with goodquality high melt<strong>in</strong>g po<strong>in</strong>ttaper roller bear<strong>in</strong>g greasei.e. Ret<strong>in</strong>ax ‘A’, Nulsec ‘L’ orequivalent.HUBS(c) The operat<strong>in</strong>g diametersof <strong>the</strong> axle must be clean.Remove hub cap. Check taper roller bear<strong>in</strong>g adjustmentby rock<strong>in</strong>g hub. There should be little or no perceptibleshake but should be complete freedom to rotate. (Forlubrication of taper roller bear<strong>in</strong>gs see “Assembly ofhubs fitted with taper roller bear<strong>in</strong>gs”).(d) The taper roller bear<strong>in</strong>gcones must be greased as(b) ensur<strong>in</strong>g that <strong>the</strong>grease penetrates <strong>in</strong>side<strong>the</strong> roller cage, between<strong>the</strong> rollers and <strong>the</strong> cones,2