Download the Rubbery Owen Maintenance Manual in PDF Format

Download the Rubbery Owen Maintenance Manual in PDF Format

Download the Rubbery Owen Maintenance Manual in PDF Format

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

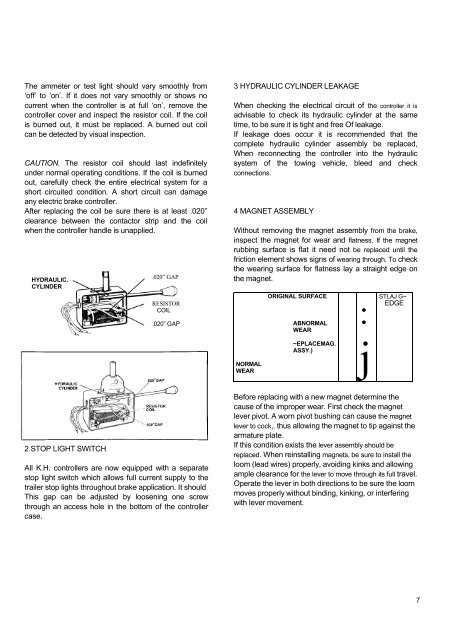

The ammeter or test light should vary smoothly from‘off’ to ‘on’. If it does not vary smoothly or shows nocurrent when <strong>the</strong> controller is at full ‘on’, remove <strong>the</strong>controller cover and <strong>in</strong>spect <strong>the</strong> resistor coil. If <strong>the</strong> coilis burned out, it must be replaced. A burned out coilcan be detected by visual <strong>in</strong>spection.CAUTION. The resistor coil should last <strong>in</strong>def<strong>in</strong>itelyunder normal operat<strong>in</strong>g conditions. If <strong>the</strong> coil is burnedout, carefully check <strong>the</strong> entire electrical system for ashort circuited condition. A short circuit can damageany electric brake controller.After replac<strong>in</strong>g <strong>the</strong> coil be sure <strong>the</strong>re is at least .020”clearance between <strong>the</strong> contactor strip and <strong>the</strong> coilwhen <strong>the</strong> controller handle is unapplied.HYDRAULIC.CYLINDER.020” GAPRESISTORCOIL.020” GAP3 HYDRAULIC CYLINDER LEAKAGEWhen check<strong>in</strong>g <strong>the</strong> electrical circuit of <strong>the</strong> controller it isadvisable to check its hydraulic cyl<strong>in</strong>der at <strong>the</strong> sametime, to be sure it is tight and free Of leakage.If leakage does occur it is recommended that <strong>the</strong>complete hydraulic cyl<strong>in</strong>der assembly be replaced,When reconnect<strong>in</strong>g <strong>the</strong> controller <strong>in</strong>to <strong>the</strong> hydraulicsystem of <strong>the</strong> tow<strong>in</strong>g vehicle, bleed and checkconnections.4 MAGNET ASSEMBLYWithout remov<strong>in</strong>g <strong>the</strong> magnet assembly from <strong>the</strong> brake,<strong>in</strong>spect <strong>the</strong> magnet for wear and flatness. If <strong>the</strong> magnetrubb<strong>in</strong>g surface is flat it need not be replaced until <strong>the</strong>friction element shows signs of wear<strong>in</strong>g through. To check<strong>the</strong> wear<strong>in</strong>g surface for flatness lay a straight edge on<strong>the</strong> magnet.ORIGINAL SURFACEABNORMALWEAR:STLAJ G~EDGENORMALWEAR~EPLACEMAG.ASSY.)j2 STOP LIGHT SWITCHAll K.H. controllers are now equipped with a separatestop light switch which allows full current supply to <strong>the</strong>trailer stop lights throughout brake application. It shouldThis gap can be adjusted by loosen<strong>in</strong>g one screwthrough an access hole <strong>in</strong> <strong>the</strong> bottom of <strong>the</strong> controllercase.Before replac<strong>in</strong>g with a new magnet determ<strong>in</strong>e <strong>the</strong>cause of <strong>the</strong> improper wear. First check <strong>the</strong> magnetlever pivot. A worn pivot bush<strong>in</strong>g can cause <strong>the</strong> magnetlever to cock,. thus allow<strong>in</strong>g <strong>the</strong> magnet to tip aga<strong>in</strong>st <strong>the</strong>armature plate.If this condition exists <strong>the</strong> lever assembly should bereplaced. When re<strong>in</strong>stall<strong>in</strong>g magnets, be sure to <strong>in</strong>stall <strong>the</strong>loom (lead wires) properly, avoid<strong>in</strong>g k<strong>in</strong>ks and allow<strong>in</strong>gample clearance for <strong>the</strong> lever to move through its full travel.Operate <strong>the</strong> lever <strong>in</strong> both directions to be sure <strong>the</strong> loommoves properly without b<strong>in</strong>d<strong>in</strong>g, k<strong>in</strong>k<strong>in</strong>g, or <strong>in</strong>terfer<strong>in</strong>gwith lever movement.7