ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

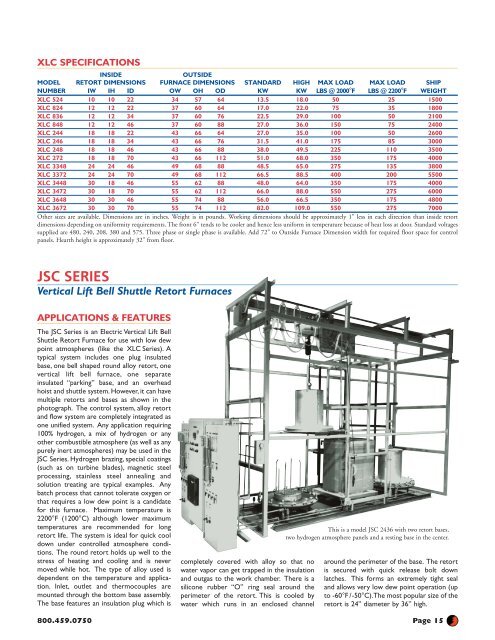

XLC SPECIFICATIONSINSIDEOUTSIDEMODEL RETORT DIMENSIONS FURNACE DIMENSIONS STANDARD HIGH MAX LOAD MAX LOAD SHIPNUMBER IW IH ID OW OH OD KW KW LBS @ 2000°F LBS @ 2200°F WEIGHTXLC 524 10 10 22 34 57 64 13.5 18.0 50 25 1500XLC 824 12 12 22 37 60 64 17.0 22.0 75 35 1800XLC 836 12 12 34 37 60 76 22.5 29.0 100 50 2100XLC 848 12 12 46 37 60 88 27.0 36.0 150 75 2400XLC 244 18 18 22 43 66 64 27.0 35.0 100 50 2600XLC 246 18 18 34 43 66 76 31.5 41.0 175 85 3000XLC 248 18 18 46 43 66 88 38.0 49.5 225 110 3500XLC 272 18 18 70 43 66 112 51.0 68.0 350 175 4000XLC 3348 24 24 46 49 68 88 48.5 65.0 275 135 3800XLC 3372 24 24 70 49 68 112 66.5 88.5 400 200 5500XLC 3448 30 18 46 55 62 88 48.0 64.0 350 175 4000XLC 3472 30 18 70 55 62 112 66.0 88.0 550 275 6000XLC 3648 30 30 46 55 74 88 56.0 66.5 350 175 4800XLC 3672 30 30 70 55 74 112 82.0 109.0 550 275 7000Other sizes are available. Dimensions are in inches. Weight is in pounds. Working dimensions should be approximately 1” less in each direction than inside retortdimensions depending on uniformity requirements. The front 6” tends to be cooler and hence less uniform in temperature because of heat loss at door. Standard voltagessupplied are 480, 240, 208, 380 and 575. Three phase or single phase is available. Add 72” to Outside Furnace Dimension width for required floor space for controlpanels. Hearth height is approximately 32” from floor.JSC SERIESVertical Lift Bell Shuttle Retort FurnacesAPPLICATIONS & FEATURESThe JSC Series is an Electric Vertical Lift BellShuttle Retort Furnace for use with low dewpoint atmospheres (like the XLC Series). Atypical system includes one plug insulatedbase, one bell shaped round alloy retort, onevertical lift bell furnace, one separateinsulated “parking” base, and an overheadhoist and shuttle system. However, it can havemultiple retorts and bases as shown in thephotograph. The control system, alloy retortand flow system are completely integrated asone unified system. Any application requiring100% hydrogen, a mix of hydrogen or anyother combustible atmosphere (as well as anypurely inert atmospheres) may be used in theJSC Series. Hydrogen brazing, special coatings(such as on turbine blades), magnetic steelprocessing, stainless steel annealing andsolution treating are typical examples. Anybatch process that cannot tolerate oxygen orthat requires a low dew point is a candidatefor this furnace. Maximum temperature is2200°F (1200°C) although lower maximumtemperatures are recommended for longretort life. The system is ideal for quick cooldown under controlled atmosphere conditions.The round retort holds up well to thestress of heating and cooling and is nevermoved while hot. The type of alloy used isdependent on the temperature and application.Inlet, outlet and thermocouples aremounted through the bottom base assembly.The base features an insulation plug which is800.459.0750completely covered with alloy so that nowater vapor can get trapped in the insulationand outgas to the work chamber. There is asilicone rubber “O” ring seal around theperimeter of the retort. This is cooled bywater which runs in an enclosed channelThis is a model JSC 2436 with two retort bases,two hydrogen atmosphere panels and a resting base in the center.around the perimeter of the base. The retortis secured with quick release bolt downlatches. This forms an extremely tight sealand allows very low dew point operation (upto -60°F / -50°C).The most popular size of theretort is 24” diameter by 36” high.Page 15