ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

ovens • kilns • quench tanks furnaces • ovens • kilns • quench tanks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

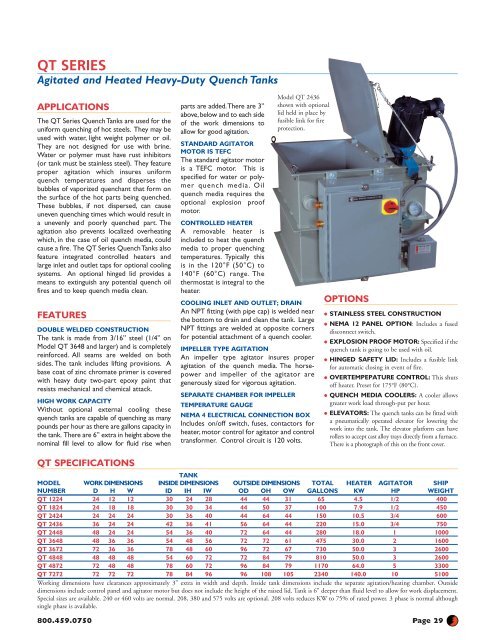

QT SERIESAgitated and Heated Heavy-Duty Quench TanksAPPLICATIONSThe QT Series Quench Tanks are used for theuniform <strong>quench</strong>ing of hot steels. They may beused with water, light weight polymer or oil.They are not designed for use with brine.Water or polymer must have rust inhibitors(or tank must be stainless steel). They featureproper agitation which insures uniform<strong>quench</strong> temperatures and disperses thebubbles of vaporized <strong>quench</strong>ant that form onthe surface of the hot parts being <strong>quench</strong>ed.These bubbles, if not dispersed, can causeuneven <strong>quench</strong>ing times which would result ina unevenly and poorly <strong>quench</strong>ed part. Theagitation also prevents localized overheatingwhich, in the case of oil <strong>quench</strong> media, couldcause a fire. The QT Series Quench Tanks alsofeature integrated controlled heaters andlarge inlet and outlet taps for optional coolingsystems. An optional hinged lid provides ameans to extinguish any potential <strong>quench</strong> oilfires and to keep <strong>quench</strong> media clean.FEATURESDOUBLE WELDED CONSTRUCTIONThe tank is made from 3/16” steel (1/4” onModel QT 3648 and larger) and is completelyreinforced. All seams are welded on bothsides. The tank includes lifting provisions. Abase coat of zinc chromate primer is coveredwith heavy duty two-part epoxy paint thatresists mechanical and chemical attack.HIGH WORK CAPACITYWithout optional external cooling these<strong>quench</strong> <strong>tanks</strong> are capable of <strong>quench</strong>ing as manypounds per hour as there are gallons capacity inthe tank. There are 6” extra in height above thenominal fill level to allow for fluid rise whenparts are added.There are 3”above, below and to each sideof the work dimensions toallow for good agitation.STANDARD AGITATORMOTOR IS TEFCThe standard agitator motoris a TEFC motor. This isspecified for water or polymer<strong>quench</strong> media. Oil<strong>quench</strong> media requires theoptional explosion proofmotor.CONTROLLED HEATERA removable heater isincluded to heat the <strong>quench</strong>media to proper <strong>quench</strong>ingtemperatures. Typically thisis in the 120°F (50°C) to140°F (60°C) range. Thethermostat is integral to theheater.Model QT 2436shown with optionallid held in place byfusible link for fireprotection.COOLING INLET AND OUTLET; DRAINAn NPT fitting (with pipe cap) is welded nearthe bottom to drain and clean the tank. LargeNPT fittings are welded at opposite cornersfor potential attachment of a <strong>quench</strong> cooler.IMPELLER TYPE AGITATIONAn impeller type agitator insures properagitation of the <strong>quench</strong> media. The horsepowerand impeller of the agitator aregenerously sized for vigorous agitation.SEPARATE CHAMBER FOR IMPELLERTEMPERATURE GAUGENEMA 4 ELECTRICAL CONNECTION BOXIncludes on/off switch, fuses, contactors forheater, motor control for agitator and controltransformer. Control circuit is 120 volts.OPTIONS● STAINLESS STEEL CONSTRUCTION● NEMA 12 PANEL OPTION: Includes a fuseddisconnect switch.● EXPLOSION PROOF MOTOR: Specified if the<strong>quench</strong> tank is going to be used with oil.● HINGED SAFETY LID: Includes a fusible linkfor automatic closing in event of fire.● OVERTEMPEPATURE CONTROL: This shutsoff heater. Preset for 175°F (80°C).● QUENCH MEDIA COOLERS: A cooler allowsgreater work load through-put per hour.● ELEVATORS: The <strong>quench</strong> <strong>tanks</strong> can be fitted witha pneumatically operated elevator for lowering thework into the tank. The elevator platform can haverollers to accept cast alloy trays directly from a furnace.There is a photograph of this on the front cover.QT SPECIFICATIONSTANKMODEL WORK DIMENSIONS INSIDE DIMENSIONS OUTSIDE DIMENSIONS TOTAL HEATER AGITATOR SHIPNUMBER D H W ID IH IW OD OH OW GALLONS KW HP WEIGHTQT 1224 24 12 12 30 24 28 44 44 31 65 4.5 1/2 400QT 1824 24 18 18 30 30 34 44 50 37 100 7.9 1/2 450QT 2424 24 24 24 30 36 40 44 64 44 150 10.5 3/4 600QT 2436 36 24 24 42 36 41 56 64 44 220 15.0 3/4 750QT 2448 48 24 24 54 36 40 72 64 44 280 18.0 1 1000QT 3648 48 36 36 54 48 56 72 72 61 475 30.0 2 1600QT 3672 72 36 36 78 48 60 96 72 67 730 50.0 3 2600QT 4848 48 48 48 54 60 72 72 84 79 810 50.0 3 2600QT 4872 72 48 48 78 60 72 96 84 79 1170 64.0 5 3300QT 7272 72 72 72 78 84 96 96 108 105 2340 140.0 10 5100Working dimensions have clearances approximately 3” extra in width and depth. Inside tank dimensions include the separate agitation/heating chamber. Outsidedimensions include control panel and agitator motor but does not include the height of the raised lid. Tank is 6” deeper than fluid level to allow for work displacement.Special sizes are available. 240 or 460 volts are normal. 208, 380 and 575 volts are optional. 208 volts reduces KW to 75% of rated power. 3 phase is normal althoughsingle phase is available.800.459.0750 Page 29