Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

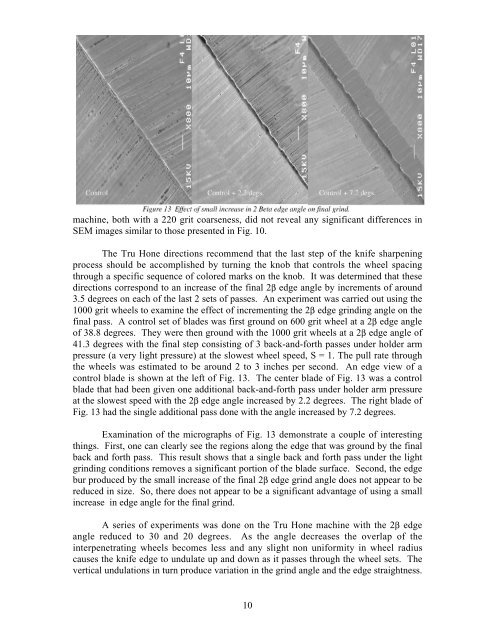

machine, both with a 220 grit coarseness, did not reveal any significant differences inSEM images similar to those presented in Fig. 10.The Tru H<strong>on</strong>e directi<strong>on</strong>s recommend that the last step of the knife sharpeningprocess should be accomplished by turning the knob that c<strong>on</strong>trols the wheel spacingthrough a specific sequence of colored marks <strong>on</strong> the knob. It was determined that thesedirecti<strong>on</strong>s corresp<strong>on</strong>d to an increase of the final 2β edge angle by increments of around3.5 degrees <strong>on</strong> each of the last 2 sets of passes. An experiment was carried out using the1000 grit wheels to examine the effect of incrementing the 2β edge grinding angle <strong>on</strong> thefinal pass. A c<strong>on</strong>trol set of blades was first ground <strong>on</strong> 600 grit wheel at a 2β edge angleof 38.8 degrees. They were then ground with the 1000 grit wheels at a 2β edge angle of41.3 degrees with the final step c<strong>on</strong>sisting of 3 back-and-forth passes under holder armpressure (a very light pressure) at the slowest wheel speed, S = 1. The pull rate throughthe wheels was estimated to be around 2 to 3 inches per sec<strong>on</strong>d. An edge view of ac<strong>on</strong>trol blade is shown at the left of Fig. 13. The center blade of Fig. 13 was a c<strong>on</strong>trolblade that had been given <strong>on</strong>e additi<strong>on</strong>al back-and-forth pass under holder arm pressureat the slowest speed with the 2β edge angle increased by 2.2 degrees. The right blade ofFig. 13 had the single additi<strong>on</strong>al pass d<strong>on</strong>e with the angle increased by 7.2 degrees.Examinati<strong>on</strong> of the micrographs of Fig. 13 dem<strong>on</strong>strate a couple of interestingthings. First, <strong>on</strong>e can clearly see the regi<strong>on</strong>s al<strong>on</strong>g the edge that was ground by the finalback and forth pass. This result shows that a single back and forth pass under the lightgrinding c<strong>on</strong>diti<strong>on</strong>s removes a significant porti<strong>on</strong> of the blade surface. Sec<strong>on</strong>d, the edgebur produced by the small increase of the final 2β edge grind angle does not appear to bereduced in size. So, there does not appear to be a significant advantage of using a smallincrease in edge angle for the final grind.A series of experiments was d<strong>on</strong>e <strong>on</strong> the Tru H<strong>on</strong>e machine with the 2β edgeangle reduced to 30 and 20 degrees. As the angle decreases the overlap of theinterpenetrating wheels becomes less and any slight n<strong>on</strong> uniformity in wheel radiuscauses the knife edge to undulate up and down as it passes through the wheel sets. Thevertical undulati<strong>on</strong>s in turn produce variati<strong>on</strong> in the grind angle and the edge straightness.10