Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

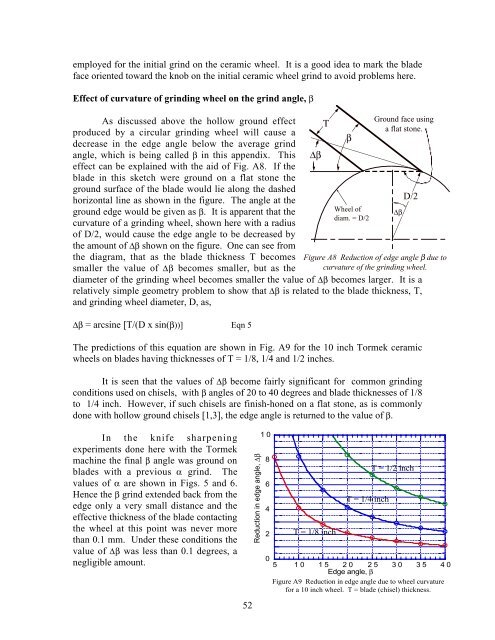

employed for the initial grind <strong>on</strong> the ceramic wheel. It is a good idea to mark the bladeface oriented toward the knob <strong>on</strong> the initial ceramic wheel grind to avoid problems here.Effect of curvature of grinding wheel <strong>on</strong> the grind angle, βAs discussed above the hollow ground effectproduced by a circular grinding wheel will cause adecrease in the edge angle below the average grindangle, which is being called β in this appendix. Thiseffect can be explained with the aid of Fig. A8. If theblade in this sketch were ground <strong>on</strong> a flat st<strong>on</strong>e theground surface of the blade would lie al<strong>on</strong>g the dashedhoriz<strong>on</strong>tal line as shown in the figure. The angle at theground edge would be given as β. It is apparent that thecurvature of a grinding wheel, shown here with a radiusof D/2, would cause the edge angle to be decreased bythe amount of ∆β shown <strong>on</strong> the figure. One can see fromthe diagram, that as the blade thickness T becomessmaller the value of ∆β becomes smaller, but as thediameter of the grinding wheel becomes smaller the value of ∆β becomes larger. It is arelatively simple geometry problem to show that ∆β is related to the blade thickness, T,and grinding wheel diameter, D, as,∆β = arcsine [T/(D x sin(β))] Eqn 5The predicti<strong>on</strong>s of this equati<strong>on</strong> are shown in Fig. A9 for the 10 inch Tormek ceramicwheels <strong>on</strong> blades having thicknesses of T = 1/8, 1/4 and 1/2 inches.It is seen that the values of ∆β become fairly significant for comm<strong>on</strong> grindingc<strong>on</strong>diti<strong>on</strong>s used <strong>on</strong> chisels, with β angles of 20 to 40 degrees and blade thicknesses of 1/8to 1/4 inch. However, if such chisels are finish-h<strong>on</strong>ed <strong>on</strong> a flat st<strong>on</strong>e, as is comm<strong>on</strong>lyd<strong>on</strong>e with hollow ground chisels [1,3], the edge angle is returned to the value of β.In the knife sharpeningexperiments d<strong>on</strong>e here with the Tormekmachine the final β angle was ground <strong>on</strong>blades with a previous α grind. Thevalues of α are shown in Figs. 5 and 6.Hence the β grind extended back from theedge <strong>on</strong>ly a very small distance and theeffective thickness of the blade c<strong>on</strong>tactingthe wheel at this point was never morethan 0.1 mm. Under these c<strong>on</strong>diti<strong>on</strong>s thevalue of ∆β was less than 0.1 degrees, anegligible amount.52Reducti<strong>on</strong> in edge angle, ∆β108642∆βΤβWheel ofdiam. = D/2Ground face usinga flat st<strong>on</strong>e.∆βD/2Figure A8 Reducti<strong>on</strong> of edge angle β due tocurvature of the grinding wheel.T = 1/8 inchT = 1/4 inchT = 1/2 inch05 10 15 20 25 30 35 40Edge angle, βFigure A9 Reducti<strong>on</strong> in edge angle due to wheel curvaturefor a 10 inch wheel. T = blade (chisel) thickness.