Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

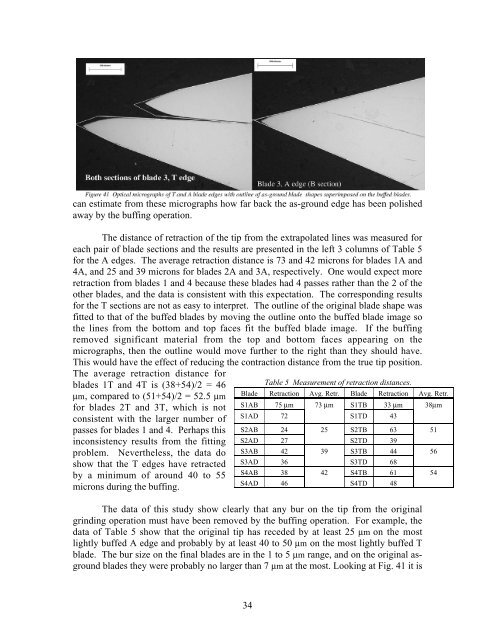

can estimate from these micrographs how far back the as-ground edge has been polishedaway by the buffing operati<strong>on</strong>.The distance of retracti<strong>on</strong> of the tip from the extrapolated lines was measured foreach pair of blade secti<strong>on</strong>s and the results are presented in the left 3 columns of Table 5for the A edges. The average retracti<strong>on</strong> distance is 73 and 42 micr<strong>on</strong>s for blades 1A and4A, and 25 and 39 micr<strong>on</strong>s for blades 2A and 3A, respectively. One would expect moreretracti<strong>on</strong> from blades 1 and 4 because these blades had 4 passes rather than the 2 of theother blades, and the data is c<strong>on</strong>sistent with this expectati<strong>on</strong>. The corresp<strong>on</strong>ding resultsfor the T secti<strong>on</strong>s are not as easy to interpret. The outline of the original blade shape wasfitted to that of the buffed blades by moving the outline <strong>on</strong>to the buffed blade image sothe lines from the bottom and top faces fit the buffed blade image. If the buffingremoved significant material from the top and bottom faces appearing <strong>on</strong> themicrographs, then the outline would move further to the right than they should have.This would have the effect of reducing the c<strong>on</strong>tracti<strong>on</strong> distance from the true tip positi<strong>on</strong>.The average retracti<strong>on</strong> distance forblades 1T and 4T is (38+54)/2 = 46 Table 5 Measurement of retracti<strong>on</strong> distances.µm, compared to (51+54)/2 = 52.5 µmfor blades 2T and 3T, which is notc<strong>on</strong>sistent with the larger number ofpasses for blades 1 and 4. Perhaps thisinc<strong>on</strong>sistency results from the fittingproblem. Nevertheless, the data doshow that the T edges have retractedby a minimum of around 40 to 55micr<strong>on</strong>s during the buffing.S1ABS1ADS2ABS2ADS3ABS3ADS4ABS4AD75 µm7224274236384673 µm253942S1TBS1TDS2TBS2TDS3TBS3TDS4TBS4TD33 µm43633944686148Blade Retracti<strong>on</strong> Avg. Retr. Blade Retracti<strong>on</strong> Avg. Retr.The data of this study show clearly that any bur <strong>on</strong> the tip from the originalgrinding operati<strong>on</strong> must have been removed by the buffing operati<strong>on</strong>. For example, thedata of Table 5 show that the original tip has receded by at least 25 µm <strong>on</strong> the mostlightly buffed A edge and probably by at least 40 to 50 µm <strong>on</strong> the most lightly buffed Tblade. The bur size <strong>on</strong> the final blades are in the 1 to 5 µm range, and <strong>on</strong> the original asgroundblades they were probably no larger than 7 µm at the most. Looking at Fig. 41 it is38µm51565434