Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

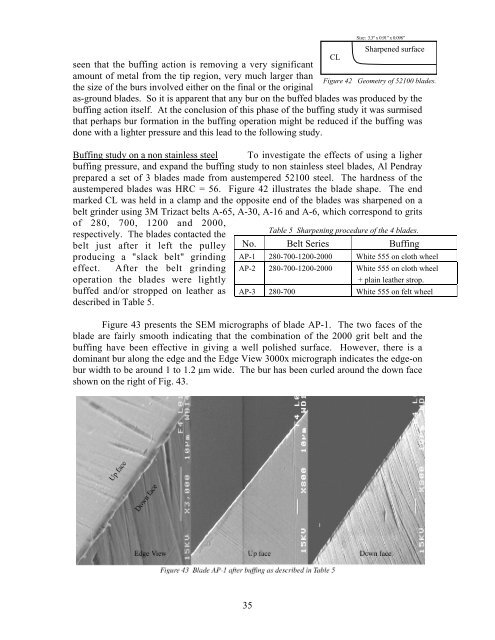

seen that the buffing acti<strong>on</strong> is removing a very significantamount of metal from the tip regi<strong>on</strong>, very much larger thanthe size of the burs involved either <strong>on</strong> the final or the originalas-ground blades. So it is apparent that any bur <strong>on</strong> the buffed blades was produced by thebuffing acti<strong>on</strong> itself. At the c<strong>on</strong>clusi<strong>on</strong> of this phase of the buffing study it was surmisedthat perhaps bur formati<strong>on</strong> in the buffing operati<strong>on</strong> might be reduced if the buffing wasd<strong>on</strong>e with a lighter pressure and this lead to the following study.Buffing study <strong>on</strong> a n<strong>on</strong> stainless steel To investigate the effects of using a ligherbuffing pressure, and expand the buffing study to n<strong>on</strong> stainless steel blades, Al Pendrayprepared a set of 3 blades made from austempered 52100 steel. The hardness of theaustempered blades was HRC = 56. Figure 42 illustrates the blade shape. The endmarked CL was held in a clamp and the opposite end of the blades was sharpened <strong>on</strong> abelt grinder using 3M Trizact belts A-65, A-30, A-16 and A-6, which corresp<strong>on</strong>d to gritsof 280, 700, 1200 and 2000,Table 5 <strong>Sharpening</strong> procedure of the 4 blades.respectively. The blades c<strong>on</strong>tacted thebelt just after it left the pulley No. Belt Series Buffingproducing a "slack belt" grindingeffect. After the belt grindingoperati<strong>on</strong> the blades were lightlybuffed and/or stropped <strong>on</strong> leather asdescribed in Table 5.AP-1 280-700-1200-2000 White 555 <strong>on</strong> cloth wheelAP-2 280-700-1200-2000 White 555 <strong>on</strong> cloth wheel+ plain leather strop.AP-3 280-700 White 555 <strong>on</strong> felt wheelFigure 43 presents the SEM micrographs of blade AP-1. The two faces of theblade are fairly smooth indicating that the combinati<strong>on</strong> of the 2000 grit belt and thebuffing have been effective in giving a well polished surface. However, there is adominant bur al<strong>on</strong>g the edge and the Edge View 3000x micrograph indicates the edge-<strong>on</strong>bur width to be around 1 to 1.2 µm wide. The bur has been curled around the down faceshown <strong>on</strong> the right of Fig. 43.CLSize: 3.3" x 0.91" x 0.098"Sharpened surfaceFigure 42 Geometry of 52100 blades.35