Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Experiments on Knife Sharpening John D. Verhoeven ... - BushcraftUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

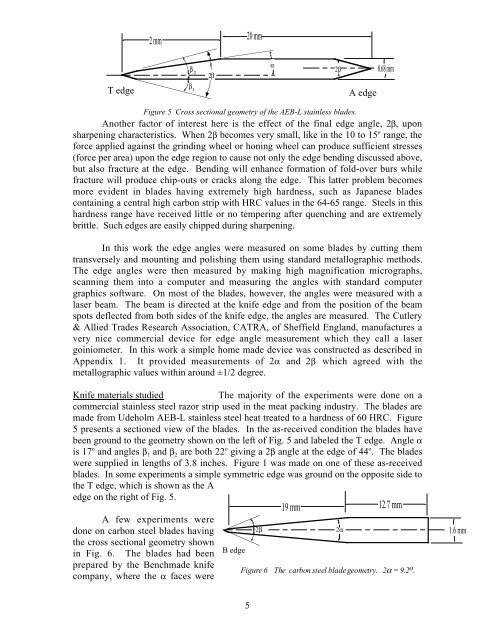

2 mm20 mmβ 22βα2β0.68 mmT edgeβ 1A edgeFigure 5 Cross secti<strong>on</strong>al geometry of the AEB-L stainless blades.Another factor of interest here is the effect of the final edge angle, 2β, up<strong>on</strong>sharpening characteristics. When 2β becomes very small, like in the 10 to 15 o range, theforce applied against the grinding wheel or h<strong>on</strong>ing wheel can produce sufficient stresses(force per area) up<strong>on</strong> the edge regi<strong>on</strong> to cause not <strong>on</strong>ly the edge bending discussed above,but also fracture at the edge. Bending will enhance formati<strong>on</strong> of fold-over burs whilefracture will produce chip-outs or cracks al<strong>on</strong>g the edge. This latter problem becomesmore evident in blades having extremely high hardness, such as Japanese bladesc<strong>on</strong>taining a central high carb<strong>on</strong> strip with HRC values in the 64-65 range. Steels in thishardness range have received little or no tempering after quenching and are extremelybrittle. Such edges are easily chipped during sharpening.In this work the edge angles were measured <strong>on</strong> some blades by cutting themtransversely and mounting and polishing them using standard metallographic methods.The edge angles were then measured by making high magnificati<strong>on</strong> micrographs,scanning them into a computer and measuring the angles with standard computergraphics software. On most of the blades, however, the angles were measured with alaser beam. The beam is directed at the knife edge and from the positi<strong>on</strong> of the beamspots deflected from both sides of the knife edge, the angles are measured. The Cutlery& Allied Trades Research Associati<strong>on</strong>, CATRA, of Sheffield England, manufactures avery nice commercial device for edge angle measurement which they call a lasergoiniometer. In this work a simple home made device was c<strong>on</strong>structed as described inAppendix 1. It provided measurements of 2α and 2β which agreed with themetallographic values within around ±1/2 degree.<strong>Knife</strong> materials studiedThe majority of the experiments were d<strong>on</strong>e <strong>on</strong> acommercial stainless steel razor strip used in the meat packing industry. The blades aremade from Udeholm AEB-L stainless steel heat treated to a hardness of 60 HRC. Figure5 presents a secti<strong>on</strong>ed view of the blades. In the as-received c<strong>on</strong>diti<strong>on</strong> the blades havebeen ground to the geometry shown <strong>on</strong> the left of Fig. 5 and labeled the T edge. Angle αis 17 o and angles β 1 and β 2 are both 22 o giving a 2β angle at the edge of 44 o . The bladeswere supplied in lengths of 3.8 inches. Figure 1 was made <strong>on</strong> <strong>on</strong>e of these as-receivedblades. In some experiments a simple symmetric edge was ground <strong>on</strong> the opposite side tothe T edge, which is shown as the Aedge <strong>on</strong> the right of Fig. 5.A few experiments wered<strong>on</strong>e <strong>on</strong> carb<strong>on</strong> steel blades havingthe cross secti<strong>on</strong>al geometry shownin Fig. 6. The blades had beenprepared by the Benchmade knifecompany, where the α faces wereB edge2β19 mm 12.7 mmFigure 6 The carb<strong>on</strong> steel blade geometry. 2α = 9.2 o .2α1.6 mm5