National - Miller Publishing Corporation

National - Miller Publishing Corporation

National - Miller Publishing Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

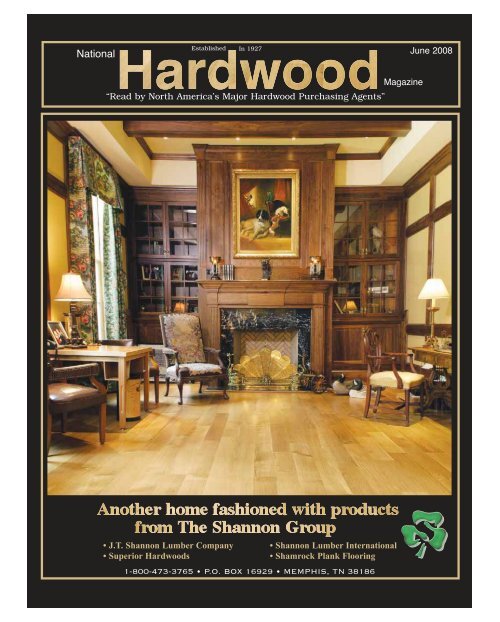

<strong>National</strong>Established In 1927June 2008“Read by North America’s Major Hardwood Purchasing Agents”Magazine• J.T. Shannon Lumber Company • Shannon Lumber International• Superior Hardwoods• Shamrock Plank Flooring1-800-473-3765 • P.O. BOX 16929 • MEMPHIS, TN 38186

WE’VEALWAYS LOVEDHARDWOOD.A SERIOUS COMMITMENT.With a 32 acre facilityand one of the Midwest’slargest on-site inventories,there’s no question how wefeel about hardwoods.The fact is, the only thingwe’re more passionate aboutis customer service.Cole Hardwood.You’re Gonna Love It.16 SpeciesLarge Volume InventoryThicknesses 4/4 up to 16/4NHLA InspectedWorldwide Distribution.We’d love to quoteyour next order. Call1-800-536-3151 or visitwww.colehardwood.com.Dave Bramlage,Sales Manager andWood Enthusiastat Age 4COLE HARDWOOD, INC.P.O. Box 568, Logansport, IN 46947Ph: 574.753-3151Fax: 574.753.2525www.colehardwood.com

C o n t e n t sRead each month’s feature stories ordownload the latest issue online @www.nationalhardwoodmag.comFeatures:Holt & Bugbee Expands Sales Force, Targets High-End Products .........26Cardwell Lumber Inc., Quality Stays True Through Three Generations....28New Facility Brings Growth For Bingaman................................................30KFIA Celebrates Service To Industry ..........................................................32Thousands Flock To NWFA Expo................................................................34Penn-Sylvan Hosts Penn-York.....................................................................38Southwestern Members Meet In Vidalia .....................................................40Speakers Inform New England Club Of Market Status .............................44Upbeat Outlook Prevails At High Point.......................................................46New President Elected At SCMA .................................................................48NHLA Graduates 155 th Class ........................................................................49Departments:Hardwood Calendar ...........................................................................................8U.S.A. Trends.................................................................................................10Canadian Trends ...........................................................................................12Eye On Technology.......................................................................................14NHLA News....................................................................................................16HMA & Solid Hardwood Promotion.............................................................18AHEC Update.................................................................................................20NOFMA Notes ................................................................................................22Who’s Who.....................................................................................................64Trade Talk.......................................................................................................68Classified Opportunities...............................................................................80Advertisers Index ..........................................................................................84The publisher reserves the right to accept or reject editorial contentand Ads at the staff’s discretion.2 Hardwoods...The All-Purpose Material

June, 2008 Vol. 82, No. 5The CoverFor five generations, The Shannon Lumber Grouphas been recognized in the Hardwood industry forexceptional value and consistent high quality. TheHardwood Professionals of J.T. Shannon LumberCompany, Inc. and its associated Hardwood divisionscontinue the long-standing commitment of providingexcellence in hardwood products to customersthroughout the world.Shannon’s Shamrock Plank Flooring Division is apreeminent manufacturer of solid and engineeredhardwood flooring in Walnut, Hickory, Cherry, andquartered and plain sawn Red Oak and White Oak.Manufacturing facilities continue to expand andprocesses refine to ensure top-of-the-line quality andproduction efficiencies.Shannon’s Indiana facility, Superior Hardwoods,with two band mills producing 30 million board feetannually evidences the Company’s commitment tomeeting customer needs in the most efficient and costeffectivemanner. J.T. Shannon Lumber Company’sflagship operation in Memphis continues to offer the quality and exceptional workmanshipwhich has made it the hallmark of The Shannon Lumber Group for years.Shannon Lumber International has facilities and personnel in China to support the growinghardwood need with increasing demand and marketing presence in Europe and Asia.Although the client base is quite different from the customer list of previous generations, theShannon Lumber Group of today is passionate about the same values of generations past — customersatisfaction and unprecedented quality and service. Customers and suppliers know TheShannon Lumber Group will continue to rank them as the Company’s number one priority.Founded in 1927 by:O.L. MILLER1894-1963The <strong>National</strong> Hardwood Magazine is the product of a company and its affiliates thathave been in the publishing business for 81 years.Other publications edited for specialized markets and distributed worldwide include:Forest Products Export Directory • Hardwood Purchasing Handbook • Dimension &Wood Components Buyer’s Guide • Import/Export Wood Purchasing News • ClassifiedExchange • Imported Wood Purchasing Guide • Green Book’s Hardwood MarketingDirectory • Green Book’s Softwood Marketing Directory • The Softwood ForestProducts BuyerPaul J. <strong>Miller</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Publisher58228 County Road 43, P.O. Box 1168Middlebury, Indiana 46540Phone: (574) 825-2129 FAX: (574) 825-7519HARDWOOD LUMBER SALES:Rick Hetler - rick@indianawood.comCharlie Steiner - csteiner@indianawood.comBill Tusing - bill@indianawood.comVENEER LOG SALES: Dean HowardMANUFACTURERS OF FINE QUALITY INDIANA &MICHIGAN GREEN & KILN DRIED HARDWOODS- 200,000’ kiln capacity - surfacing- 625,000’ pre-dryer capacity - straight line ripping- inspection after kiln drying - mixed truckloads- container loading - export preparation- 1,000,000’ kiln dried inventoryred oak, white oak, cherry, white ash,poplar, hard maple, soft maple,hickory, walnutNorthern and Appalachian HardwoodsPaul <strong>Miller</strong>, Jr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PresidentWayne <strong>Miller</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vice PresidentGary <strong>Miller</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vice President - EditorTerry <strong>Miller</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vice PresidentSue Putnam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EditorDavid Owens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Associate EditorJohn Gray, Jr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Art DirectorWalter Lee. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Asst. Art DirectorTammy Daugherty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Production ManagerTammy Daugherty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hardwood Handbook ManagerLisa Carpenter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Circulation ManagerADVERTISING OFFICES:1235 Sycamore View, Memphis, TN 38134901-372-8280 FAX 901-373-6180Reach us via the Internet at: www.nationalhardwoodmag.come-mail addresses: ADVERTISING: tammy@millerpublishing.comEDITORIAL: editor@millerpublishing.comSUBSCRIPTIONS: circ@millerpublishing.comEDITORIAL CORRESPONDENTS:Chicago, Los Angeles, High Point, Grand Rapids, Portland, TorontoControlled circulation postage paid at Memphis, TN(USPS #917-760)The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published monthly,except for two issues in December, for $55.00 per year and $65.00 (U.S. dollars) peryear for Canada by <strong>National</strong> Hardwood Magazine, Inc., 1235 Sycamore View,Memphis, TN 38134. Periodicals Postage paid at Memphis, TN. POSTMASTER:Send address changes to <strong>National</strong> Hardwood Magazine, P.O. Box 34908, Memphis,TN 38184. Publications mail agreement No. 40739074. Return undeliverableCanadian addresses to: P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.• Specializing in Cherry, Hard Maple, Soft Maple• Yards and Kilns in Owego and Berkshire, NY• Export Shipments• Green and Kiln Dried• 4/4 thru 16/4 Quality Hardwoods• Surfacing and Rip Strips Available3481 Waverly Rd., P.O. Box 360, Owego, NY 13827Ph: 607-687-2700 - Fax: 607-687-9439www.TiogaHardwoods.comJUNE/2008 3

Battle Lumber Co., Inc.Showing Our Commitment To The Future By What We Do TodayAt Battle Lumber Company, we work to maintainlong-term relationships with our customers, knowingthat our continual growth depends on them.Production is backed by hands-on involvement of theowners and the most advanced sawmill equipment inthe industry. We produce quality lumber in volume,manufacturing 50 million board feet of kiln driedHardwoods annually.• 14 kilns - 1.2 million board foot of capacity• 1.5 million board foot predryer• 100 bay kiln dried sorting system• Newman 282 planer provides S2S capabilities• Exporting over 2,500 containers per year• Container and boxcar loadingContact: Rusty LogueGeneral Manager Kiln DivisionSales ManagerP.O. Box 1147 • Wadley, Georgia 30477Phone: 478-252-1017 Fax: 478-252-9124E-mail: rlogue@battlelumberco.comWebsite: www.battlelumberco.comManufacturers of: 4/4 Red Oak, White Oak, Poplar, Southern White Ash, Hickory,Cypress, Soft MapleBattle Lumber Company, Inc. is proud to announce thestart up of its state-of-the-art finishing plant featuring BLC’sfactory finished product line, The Homestead Collection.• Producing unfinished and factoryfinished hardwood flooring• Consuming 700,000 board feet oflumber per week• Purchasing random and sortedwidth lumberFor Lumber Purchases contact:Rusty Logue 478-252-1017rlogue@battlelumberco.comJason Delves 478-781-0155 (ext. 125)jdelves@floorsforlife.com7702 Industrial HighwayMacon, Georgia 31216Phone: 478-781-0155For Flooring Sales contact:Bobby Cloer 478-781-0155 (ext. 115)bcloer@floorsforlife.comWarren Spradlin 478-781-0155 (ext. 107)wspradlin@floorsforlife.com4 Hardwoods Have Versatility

makes it easy for you to beITL <strong>Corporation</strong>dba Industrial Timber and Lumberwww.itlcorp.com23925 Commerce Park Road Beachwood, OH 44122 USAPhone: (216) 831-3140 FAX: (216) 831-4734 Toll Free: (800) 829-WOOD (9663)E-mail: sales@itlcorp.comThe FSC logo identifies products which contain wood from responsibly managed forests independently certified in accordance with the rules of the Forest Stewardship Council A.C.FSC Trademark ©1996 Forest Stewardship Council A.C. SW-COC-293 © 2006 Industrial Timber & LumberJUNE/2008 5

The 2 Leaders in Log and Lumber ProtectionCornelia Textiles (Shade-Dri TM )andU•C COATINGS (ANCHORSEAL ® )Teaming up for 1-Stop Service!U•C COATINGS is now the exclusive agent forTo order call 1-888-363-2628To order call 1-888-END COAT"We recently kiln dried 8 containers of 4/4 thru 6/4 white oaklumber that was air dried under our T sheds... enclosedwith Shade-Dri [which] reduced our degrade significantly."Hardwood Sales, Inc., Conover, North CarolinaValuable hardwoods and softwoods require thebest protection to prevent checking, stain, andother damage from the sun, wind, dirt and rain.The Shade-Dri TM patented mesh fabric designs givegood air flow for drying, and the barrier protectionof the UV-resistant polypropylene. Logs andlumber are cleaner, brighter, with less degrade . . .and therefore more valuable, for you and for yourcustomers!Using Shade-Dri TM and ANCHORSEAL ® togethermay virtually eliminate end checking and surface checking.Methods for inhibiting lumber checking are covered under US Patent Numbers 5,363,568,5,491,958, and 5,699,646 and Canadian Patent Numbers 2,086,807 and 2,193,190.And ... More New Products from U•C COATINGSBig Ol’ Bucket of S-irons5” size - 200 countFor the occasional order of logs that specifies S-ironsinstead of plastic LogSavers or FlitchSavers.Spray Can Marking PaintTREE & LOG Marking Paint• long-lasting markings, ideal for hardwood and softwood, even heavy barkHI-VIS FLUORESCENT Marking Paint• for short-term, high visibility markings, for both hardwood and softwood logsInverted Marking Paint (Upside Down Marking Paint)• specially formulated in a special spray can that works upside down• in general purpose & fluorescent colorswebsite: www.uccoatings.com email: nhm@uccoatings.com USA/CN Toll Free: 1-888-END-COAT6 Hardwoods...A Renewable Resource

Aged toperfection.Long before fast-food restaurants, high-speedtravel and surfing the internet,there wasBrenneman Lumber. Founded in 1932 by A.R.Brenneman, and now beginning its fifth generation,Brenneman Lumber today maintains A.R.’svision of integrity and old-fashioned hard work.Having evolved into one of the larger wholesalehardwood lumber firms in the United States,Brenneman Lumber supplies the finest northernAppalachian Red Oak, White Oak, HardMaple, Soft Maple, Cherry, Ash, Poplar, Beech ,as well as many other species. Call 740.397.0573 today tospeak to a Brenneman representative.★★★★Brenneman★★★★51 Parrott Street ExtensionMount Vernon, Ohio 43050740.397.0573Fax: 740.392.9498www.brennemanlumber.comGreen and Kiln Dried Appalachian Hardwoods

HARDWOOD CALENDARJUNEPenn-York Lumbermen’s Club meeting,Emporium Hardwoods, Emporium, Pa.Contact: 716-373-1000. June 16.JULYWestern Hardwood Assoc. AnnualMeeting, Fairmont Chateau Whistler,Whistler, B.C. Contact: wha@westernhardwood.org.July 12-15.Penn-York Lumbermen’s Club meeting,Ron Jones Hardwood Sales Inc., Franklin,Pa. Contact 716-373-1000. July 14.AWFS Fair, Las Vegas ConventionCenter, Las Vegas, Nev. Visit www.awfsfair.org.July 15-18.Appalachian Hardwood ManufacturersInc., Summer Family Conference, TheGreen Grove Park Inn, Asheville, N.C.Contact: 800-343-6466. July 27-29.NOFMA: The Wood FlooringManufacturers Assoc. meeting, PortlandRegency, Portland, Maine. Contact:www.NOFMA.org. July 31- Aug. 2.Southeastern Lumber ManufacturersAssoc. Inc., 2008 Annual Conference,Red Rock Casino Resort and Spa, LasVegas, Nev. Contact: 770-631-6705. July31-Aug. 2.AUGUSTPenn-York Lumbermen’s Club meeting,Deer Park Lumber, Findley Lake, N.Y.Contact: 607-594-3321. Aug. 11.International Woodworking Machinery &Furniture Supply Fair, Georgia WorldCongress Center, Atlanta, Ga. Contact:404-693-8333. Aug. 20-23.SEPTEMBERRay Kretz Industrial Forest, Forestry FieldDay, Antigo Wis. Contact: russj@kretzlumber.com.Sept. 15.Hardwood Federation Political ActionCommittee, Fall Meeting, Washington,D.C. Contact: 202-463-2705. Sept. 16-17.Hardwood Plywood & Veneer Assoc., FallConference, Omni Severin Hotel,Indianapolis, Ind. Contact: 703-435-2900.Sept. 28-30.•8 Hardwoods Have Workability

Supplier news about sales, labor, prices, trends, expansions and inventories.SOUTHEAST LAKE STATES WEST COASTAccording to sources in the Southeast,winter storms and high shipping prices aredealing big blows to lumber manufacturersin the region.A North Carolina lumber manufacturersaid his most trying issues are freightcosts and container availability.“We maybe could get 30 or 40 more dollarsout of the lumber we produce, butwe’re having to apply that to freight,” hesaid. “It’s affecting shipments and pricing,and putting more pressure on the millsthat are already struggling.”The source said he believes more millswill have to shut down in order for theship to be righted.“When you go from 2 million housingstarts to 1 million housing starts, somethinghas to change,” he said. “Somethinghas to happen on the supply side to tightenthis market up.”The contact noted that Red Oak is pickingup in certain thicknesses and grades,while Poplar continues to struggle.“Pricing is getting worse,” he said.“There’s no way you can dry and gradeNo. 2 Common Poplar, ship it to Asia andmake any money.”An Arkansas lumber manufacturer saida combination of the struggling housingmarket and related industries such as furnitureand cabinetry have contributed tothe overall decline in the lumber business.“Flooring was holding its own, but evenit has slowed down now,” he said. “We’vereceived over 15 inches more rain thannormal and are out of logs. We’re sellingwhat little we have that is on the yard drying.We’re moving kiln dried lumber prettydecent, but cheap.”Sources in the Lake States regiondescribe the current state of the lumberbusiness as “pretty tough,” noting HardMaple and Walnut are among the toughestspecies to sell.A Michigan lumber manufacturer saidcompanies have been forced to “beg,grovel and steal” to move Hard and SoftMaple. “It’s really the worst I’ve seen it in12 years,” he said, adding that Red Oakand Aspen still seem to be moving steadily.The source added, “It will probably bethe third or fourth quarter of 2009 beforebusiness really picks up. Until then, we’vejust got to keep working hard to makesure our customers are happy.”An Ohio wholesaler said his firm’s lumbersales are down roughly 20 percentyear-to-date. While a significant decline,he said others have suffered even greaterlosses.“We’ve had lower log inventoriesbecause of wet weather, and some companieshave even decreased production dueto the high cost of diesel fuel,” he said. “Idon’t see any significant changes for2008, and I don’t know how long it willgo.”The contact said White Oak and Ash arethe highest performing species, while it’sbeen a struggle to move Cherry andWalnut. “Business has been slow the lastcouple weeks, but it’s started to pick backup again thanks to the building season.”HOME SALES, PRICES GENERALLYDOWN IN LAKE STATESAccording to the recent Federal ReserveBoard’s “Beige Book,” a summary ofEXISTING HOME SALES DOWNSLIGHTLY ON WEST COASTAccording to the <strong>National</strong> Assoc. ofRealtors (NAR), existing-home salesrecently fell 1.1 percent on the West Coastto a seasonally adjusted annual rate of920,000 units, and are 29.2 percent belowa year ago. The median price on the WestCoast was $290,400, down 13.4 percentfrom 2007.“We’re not expecting a notable gain inexisting-home sales until the second halfof this year, but the improvement is anothersign that the market is stabilizing,” hesaid. “In other areas such as Sacramento,a rapid price decline has induced buyersto come into the market and sales are nowrising. The relationship between homeprices, interest rates and income hasimproved to the point where buyers aremore serious about making offers.”Nationwide, existing-home sales rose2.9 percent to a seasonally adjusted annualrate of 5.03 million units, but remain23.8 percent below the 6.60 million-unitlevel reported in 2007.The national median existing-homeprice for all housing types was $195,900,down 8.2 percent from a year earlier whenthe median was $213,500. Lawrence Yun,NAR chief economist, said the mostrecent data shows roughly half of themetro areas in the U.S. with price increases.DEMAND LIKELY TO KEEPGAS PRICES HIGHAccording to the Energy InformationAdministration (EIA), high crude oilPlease turn to page 75 Please turn to page 76Please turn to page 7710 Hardwoods Have Resiliency

Branching Out Worldwidewww.ahwood.com | sales@ahwood.comEmporiumHardwoodsGrahamLumberJUNE/2008 11

QUEBECSupplier news about sales, labor, prices,trends, expansions and inventories.Quebec and Appalachian area mills and wholesalers are strugglingto attract and maintain new customers. Even the longstandingcustomer base is not a guarantee for orders these days. This is seenfor kiln dried FAS Red Oak, according to comments received fromthe industry. The demand is well below the supply to absorb thetotal production.Some report that slower payments from customers are restrictingtheir cash flow. The high fuel prices are also causing concernsthroughout the industry. Trucking companies have been unable topass these costs along at the rate they have been incurred, and havetherefore had to cut their fleets. Some overseas shippers indicatedthey are experiencing delays waiting to receive containers, whileocean freight costs have risen dramatically as well. Delays areattributed to the lack of fewer goods arriving from Asia and othersupplier markets.The slow housing market is restricting the Oak strip flooringindustry. Manufacturers have reduced their production, and are stillpressed to keep developing supplies moved out.Suppliers are seeking available production of Ash, as wet weathertightened its supply earlier in the year.Use of Red Oak is down reported contacts. Curbed sawmill productionhas seen supplies fairly well balanced with buyers’ needs,and prices are stable. Shipments of kiln dried No. 1 Common haveimproved to a degree in terms of volumes, but prices are mixed.White Oak demand has tapered off somewhat, and in Europeespecially, where there is increased competition from Asian suppliers.Poplar is also seeing a decline in demand both on the domesticand international markets. This is due to the slowdown in the U.S.housing market.The slowing U.S. economy is taking a toll on the industry. Severalmore companies have reduced their hours, or shut down a shift.Unfortunately for some, they have had to close their doors.The wooden pallet and container manufacturers have also beenaffected by the U.S. recession. Sawmill production has decreased,Please turn to page 78ONTARIOTremendous effort is being exerted to maintain new business, andestablished customer relationships are not guaranteed to produceorders, comment contacts in the industry. The ones who can immediatelyship determine who gets orders. Sawmillers are reportingtight cash flow, as they are carrying large inventories necessary tofulfill secondary manufacturers’ short term needs. Fuel and deliverycosts are also affecting the trucking industry in the province, asthese costs are almost impossible to pass on to the customer. Fewertrucks have been reported as available to transport logs and otherproducts.Upper grade supplies of Aspen are marginally adequate to satisfythe demand. Hard Maple supplies of green stocks have been morethan sufficient to satisfy buyers’ needs and are readily meetingdemand. Soft Maple demand from the cabinet sector is reported tobe down as well. Soft Maple is competing against imported speciesfor market share. With total consumption down, prices for 4/4 No.1 Common have trended lower.Earlier in the year and up until recently, White Oak has been thebright spot for several sawmills. Some have exported this speciesoverseas, especially the kiln dried No. 1 Common and Bettergrades. Available supply remains steady, and supports the currentmarket demand.The Ontario Finance Minister tabled his budget in late March.Businesses were hoping for much needed tax cuts, which unfortunately,did not materialize. The modest tax measures for business,in fact, did little to satisfy neither the Federal Minister nor the businesses.The budget focussed on spending for transit and other infrastructureprojects ($1 billion), and $334 million for skills trainingfor fiscal year ended March 31st. The budget, it is reported,includes a $600 million “buffer,” in the event that revenues declinefurther than forecast. The capital tax, however, has been eliminatedretroactive to January 1, 2007, a year earlier than initiallyplanned. This will provide $190 million in rebates for manufacturers.The province is also granting a 10-year tax holiday to newPlease turn to page 7812 Hardwoods...The All-Purpose Material

Eye OnTechnologyTECTRONIX INTRODUCES SHARKLOG X-RAYTectronix Systems Inc., headquartered in Surrey, B.C., recentlyintroduced the SHARKLog, an X-Ray device to help sawmillsdetermine the quality of logs before they enter the mill and gradesort for best recovery.Tectronix’s SHARKLog X-Ray machineBenefits of the SHARKLog include: helping customers differentiatebetween the butt, intermediate and top of a log; log density;ring growth to .1mm; heartwood diameter and share; physical volumeof log and bark; distance between whorls; total number of sectionin a log; log length; species differentiation; easy link to optimizationsoftware; and 650fpm scanning speed.Tectronix Systems Inc. began manufacturing and selling metaldetection equipment in 1993, and has evolved into a leading supplier,servicing forestry and other industries with worldwide distribution.The company is known for its metal detection systemsusing Metal Shark technology. For more information, contactTectronix Systems Inc. at 604-607-6028 or e-mail gbalmer@metalshark.com.DMSI TO RELEASE PARTNERVIEW 2.0DMSi Software, based in Omaha, Neb., recently introducedPartnerView 2.0, a new, more powerful and easier-to-use web customerservice application. Available to customers alongside Agilityv3.1.0, PartnerView 2.0 (PV2.0) serves as a real-time online portalto help customers and internal staff complete their own orders andanswer questions regarding accounts, pricing and availability ofA screen shot of DMSi Software’s new PartnerView 2.0 program.14 Hardwoods Have Versatility

Installation,Products andServicesproducts with real-time data.PV2.0 users have unlimited access to real-time data from any webenabled PC or mobile device. PartnerView is completely integratedinto DMSi’s business management system, and offers the abilityto examine orders and shipments, eliminates redundant searchesand reduce errors. The PartnerView portal also works withStockNET to display full-color graphic catalogs for online orderentry.“Many DMS+ and BLOCS customers currently using EntryNet,StockNet, and PV1.0 can attest that ‘doing business online’ isbecoming a required service for those buying from wholesale distributorsand an invaluable tool to lower costs,” said Rick Olejnik,DMSi’s vice president of productivity solutions. “The ability toprovide customers instant access to information such as pricing,inventory availability and order status, allows a distributor toincrease their customer service while decreasing their costs.”For over 30 years, DMSi has been the leading business managementsolution for distributors of building material and forest products.Nearly 400 of North America’s top building product suppliersuse DMSi software to efficiently manage daily activities.WOOD-MIZER INTRODUCES WIRELESSREMOTE HEAD CONTROLWood-Mizer Products Inc., located in Indianapolis, Ind., recentlyintroduced a wireless remote option that conveniently operatesthree of the company’s thin-kerf, portable sawmills (the LT40Super Hydraulic, LT50 and the LT70).Wood-Mizer’s Wireless Remote Head Control operates three of the company’sthin-kerf, portable sawmills.With the unit, sawyers can operate the up/down, forward/reverse,blade guide arm and other head controls from any practical viewingdistance. The remote is designed to be worn around the waistor with the standard break-a-way shoulder strap, placing the joystickand toggle controls at the user’s fingertips.“In our mobile society, wireless is becoming a way of life, and wewanted our Wood-Mizer sawyers to have that same freedom,” saidDave Mann, Wood-Mizer’s vice president of the portable sawmilldivision. “That is why we engineered a way for them to operatetheir mill from any position around the entire 360-degree operatingarea and maximize their efficiency.”Wood-Mizer is a leading manufacturer of portable band sawmills,and offers an extensive line of mills covering a wide range of cuttingcapabilities. The company has sold more than 40,000 sawmillsworldwide, spanning more than 110 countries.•JUNE/2008 15

GILBERT HARDWOODS, INC.P.O. Box 129 • Trinity, NC 27370Phone (336) 431-2127Web site: www.gilberthardwood.comAttention to detail is what helps us stand out as a supplier of quality AppalachianHardwood lumber. We work hard to make sure you receive the best lumber yieldfor your investment.North CarolinaGilbert Hardwood Centers, Inc.P.O. Box 129, Trinity, NC 27370Tel. (336) 431-2127Fax (336) 861-1939Outside NC 1-800-334-2808Inside NC 1-800-422-8295E-mail: gilberthc@northstate.netPresident/Co-owner:John HendersonSales Contacts:Gary HillEd WhiteScott JarrettRegina HendersonSubsidiaries at:TennesseeGilbert Hardwood Centers, Inc. of TNP.O. Box 130, Huntland, TN 37345Tel. (931) 469-7508Fax (931) 469-75831-800-624-3551E-mail: ghctn@tnns.netPresident/Co-owner:John HendersonVice President/General Manager:Steve TurnerSales Contacts:Roger KeithStanley TrenthamJeff BrothersHolly StewartAt each location, we have 300,000 BF of Dry Kiln capacity and2,000,000 BF of KD inventory. We offer our customers surfacing on2 sides with our Yates American B-24 Planers and/or straight line ripping.We make your delivery of quality lumber in our Roll-Tite coveredtrucks which keeps your lumber clean and consistently dry whilein transit.Call us when we can be of service.When Quality Counts...KITCHENSBROTHERS MANUFACTURING990,000’ Dry Kiln Capacity1,900,000’ Predryer CapacityPRODUCING LUMBER, DIMENSION, RED & WHITE OAK STRIP FLOORING,MOULDINGSAND CUT-TO-SIZE FURNITURE PARTSSAWMILLS AT: Utica - Hazlehurst, Mississippiand Monroe, LouisianaSales Office:John Clark - Sales Manager - E-mail: jlc1102@aol.comKirby Field - Sales Representative - E-mail: kbmckf@aol.comP.O. Box 111 Hazlehurst, Miss. 39083Tel: 601-894-2021 Fax: 601-894-1069Web sites: www.kitchensbrothers.com or www.cherrybark.netNHLA News2008 NHLA Annual Convention & Exhibit Showcase:“Global Gathering of the Hardwood Community”by MARK BARFORD, CAENHLA Executive Manager<strong>National</strong> Hardwood Lumber Assoc.Memphis, Tenn.The 2008 NHLA Annual Convention &Exhibit Showcase will be held in SanFrancisco, Calif., on Oct. 9-11, 2008.Probably the most anticipated Hardwoodevent of the year, this one promises to build upon the excitement ofthe 2007 Convention. As always, the Convention will featurekeynote speakers, educational seminars, and the Exhibit Showcase,along with the usual networking and entertainment opportunities.Once again, NHLA will have two keynote speakers addressingcurrent affairs and the industry. The Opening Session keynotespeaker is Tony Snow and the second General Session keynotespeaker is Chuck Leavell.An accomplished journalist, Mr. Snow has served as White HousePress Secretary to President George W. Bush and as a speechwriterfor President George H. W. Bush. He has also worked in televisionjournalism as the anchor of FOX News Sunday.Mr. Leavell may be the world’s only tree farmer, author, and rockand roll musician. He is currently a keyboardist who tours andrecords with the Rolling Stones and is a former member of theAllman Brothers Band. A modern conservationist, he and his wifeown a tree farm in Georgia, and he is the author of Forever Greenand The Tree Farmer. Attendees will also get to enjoy his musicaltalents when he performs at the Grand Finale Dinner.The Convention’s educational seminars are the place to learn notonly where the Hardwood industry is, but where it is going. Oneseminar will focus on the certification issues facing the industrydomestically and globally. Another seminar will address economicissues stressing the Hardwood industry. Experts from all over theworld will be participating on various panels designed to giveattendees the information they need to succeed in a challengingenvironment. Additionally, the Hardwood Forest Foundation willgive its popular Truth About Trees presentation.The Exhibit Showcase continues to grow with the latest productsand services. Last year’s successful Traders Alley returns this yearas the place for producers and buyers of North AmericanHardwood to showcase their products and make a few deals. Thisyear, the lounge in the exhibit hall will be located in Traders Alley.So many of NHLA’s members are also involved in other partnerassociations that they hold meetings in conjunction with ourConvention. Not only will NHLA be meeting, so will other groupssuch as the American Hardwood Export Council, Hardwood ForestFoundation, Hardwood Distributors Association, and CanadianLumbermen’s Association, and others. Attending the Conventionis your chance to leverage your time to get even more businessdone with other associations or learn more about how to get morePlease turn to page 7316 Hardwoods...A Renewable Resource

Husky Hardwood Lumber“Division of Commonwealth Plywood”Manufacturers ofNorthern Hardwood &Eastern White Pinewww.commonwealthplywood.com15 Boul. Labelle Ste-Therese, QuebecCanada J7E 4H9Ste-Therese Office Richard Lavallee 450-435-6541 rlavallee@huskylumber.comPembroke Office Chris Sanzo 613-732-7337 csanzo@huskylumber.comImporters of fine flooring, lumber and deckingICH is a major importer of Tropical Hardwoods basedin Currie, NC. Our extensive inventory includesover 45 different species from all around the world.• 38 Acre Yard• 320,000 Bft. Drying Capacity• S2S and Ripping Available• Group Sawmills in Congo and Gabon (CIB and GIB)Genuine and African Mahogany, Sapele, Sipo, Jatoba, Ipe, Purpleheartand Padouk are just some of the species we carry. Call us for moreinformation or check out our website for a complete list.Four Diamond Floors TMPO Drawer 119 Currie, NC 28435Ph 910-283-9960 • Fax 910-283-9964www.ichardwoods.com • info@ichardwoods.comHMA & Solid HardwoodPromotionHMA <strong>National</strong> Conference & Expo –Something for Everyoneby GIL THURExecutive Vice PresidentHardwood Manufacturers AssociationPittsburgh, Pa.More than 240 individuals traveled toSavannah, Ga., recently to attend the HardwoodManufacturers Association’s 2008 <strong>National</strong>Conference & Expo. Two intense days of speakers,meetings and exhibits provided somethingfor everyone.And the meeting survey results and commentsfrom attendees were overwhelmingly positive:• 100% of the respondents said the HMA 2008 <strong>National</strong> Conferencemet their overall expectations.• 70% rated the overall take home value of the meeting as High. Thebalance rated it as above average or average.• 66% of respondents rated the meeting Outstanding or AboveAverage as compared to other Hardwood industry meetings attended inthe past year. The balance rated it equal in value or better than thoseother meetings.A sampling of comments include:• “The fellowship and networking with other members is always thebest. Our members are very open.”• “The meeting was great and very beneficial … we enjoy the networkingwith other sawmills and the open exchange of informationand ideas.”• “The HMA program is our number one event each year in terms ofvalue to our bottom line. I always invest in taking 3 or 4 leaders of ourcompany and spouses.”• “I always enjoy the speakers and discuss the topics when I get backto my company.”• “I always gain something from the speakers.”• “The talks on economic conditions in our industry always help inmy business planning.”• “Great ideas on dealing with the work force … lots of take-homevalue … a few ideas I will utilize immediately.”• “Virtually all market segments were addressed … the stats to backit up help us make decisions on a course of action.”• “We have a great time and learn a lot at the conventions about dayto-daybusiness operations and mill equipment.”• “HMA enables us to learn and grow from the experiences of othersin the Hardwood industry.”During the annual business meeting, new HMA officers were elected.They are: president, Troy Brown, Kretz Lumber Co., Antigo, Wis.;first vice president, Terry Brennan, Baillie Lumber Co., Hamburg,N.Y.; and second vice president, Pem Jenkins, Turn Bull Lumber Co.,Elizabethtown, N.C.Attendees heard more than a dozen speakers covering a broad rangeof topics, from global marketing to maximizing the workforce.Reports by three HMA-supported groups –Hardwood Federation, NewPlease turn to page 7418 Hardwoods Have Workability

P.O. Box 247 • Akron, IN 46910 • 800-356-4554 • 574-893-4511 • fax:574-893-7400 • www.pikelumber.com • e-mail: sales@pikelumber.com

James Grezenski ForestProducts, Inc.3158 County Road X-NorthStevens Point, WI 54481Tel. (715) 344-0878 FAX (715) 344-1470866-344-0878Email: jmgfp@choiceonemail.comSales - Jim GrezenskiSpecies:Red & White Oak, Hard & Soft Maple,Basswood, Ash, Birch, Butternut,Cherry, HickoryWe produce 7.5 million ft. annuallyof 4/4 grade lumber, as well as pallet lumber& cants in various thicknesses that isavailable either Green or Kiln Dried.AHECUpdateAHEC Submits Preliminary Results of“An Assessment of Lawful Harvesting &Sustainability of U.S. Hardwood Exports”by MICHAEL SNOWExecutive DirectorAmerican Hardwood Export CouncilWashington, D.C.This study forms part of AHEC’s efforts toprovide reliable objective evidence todemonstrate that U.S. Hardwoods conformto emerging international procurementrequirements both in the public and privatesectors of key overseas markets. Those policies–most notably inEurope and Japan, but with repercussions throughout the globalHardwood value chain—require that all imported wood is derivedfrom verified legal sources and that wood from various categoriesof controversial source is avoided.The AHEC-funded study evaluates the risk of illegal Hardwoodtimber being in the mix of U.S. Hardwood product exports. Itspecifically evaluates these exports in relation to UK governmentprocurement guidelines for legal and sustainable wood productsdeveloped by the Central Point of Expertise on Timber (CPET). Inaddition, it evaluates the risk of U.S. Hardwoods including productsfrom unacceptable sources as defined in the FSC ControlledWood standards and from controversial sources defined in theProgram for the Endorsement of Forest Certification (PEFC) Chainof Custody standard.To assure the quality and objectivity of this research, AHEC commissionedan independent and internationally-renowned team ofacademics and consultants with detailed knowledge of U.S.forestry policy and practices to undertake the work. To furtherenhance confidence in this work, AHEC believes the report shouldbe subject to wide-ranging peer review in advance of widespreaddistribution, and has sent advanced copies to a number of governmental,commercial and non-governmental organizations in theU.S. and abroad for comment. Once these comments are taken intoaccount, the full report will be released to the public early June.The report concludes that the weight of evidence strongly indicatesthat there is very low risk that U.S. Hardwood exports containwood from illegal sources. It notes that while timber theft occursand is of concern to private landowners, it is not a pervasive or systemicproblem. It estimates that stolen timber represents less than1% of total U.S. Hardwood production. The report concludes thatthere can be high confidence regarding adherence to national andstate laws in the Hardwood sector.The authors also have a high confidence that Hardwood procuredfrom the United States could be considered Low Risk in all fivePlease turn to page 7320 Hardwoods Have Resiliency

Boards InThe World Are Made HereThe MostBeautifulAll of us at Gilco Lumber Inc. are very proud of our logowhich is shown above on a bundle of our Poplar lumber.Our dedication to quality at our GILCO facility is obvious to any visitor. Our 20 acre site in Roderfield, West Virginiaincludes a 1,000,000 board feet capacity pre-dryer, 16 Irvington Moore dry kilns, air drying sheds and yard with 5million board feet of open air drying capacity. We have two grading chains; one to grade inbound green lumber,and the other to grade, sort and surface dried lumber to customer specifications. At the end of this grading chain,we have two 1,000,000 board feet kiln dried storage warehouses, which enable us to provide our customers with“just-in-time” shipments to any location in the world by route of truck, railcar or container. This facility was constructedwith three things in mind: Quality, Service and Consistency.QUALITY • The latest technology in quality lumber production. • All lumber trimmed after drying.• Highest quality Appalachian hardwoods. • GILCO quality Assurance.SERVICE • Controlled “just-in-time” shipments by rail, truck or container. • Ability to surface and trim to yourspecifications. • Dedicated employees committed to providing you with the highest quality of goods and services.• Flexibility to meet your needs.CONSISTENCY • Select harvest area from over 1,200,000 acres we own or manage insures you betterconsistency in grain and color. • Length and width tallies on each bundle. • Lumber produced by four GILCOsawmills with over 70,000,000 board feet annual production.*We recently acquired a new Hardwood lumber concentration yard in Marion, N.C., which will produce an additional15,000,000 board feet of kiln dried lumber annually.*a division of International Lumber Inc.Contact us when we can be of service.Phone: 304-746-3160 1-800-718-1488 FAX: 304-746-2999 www.gilcolumber.com96 MacCorkle Ave., SW P.O. Box 18370South Charleston, WV 25303-8370Sales - Scott England, Hank Bishop and Tony Love

NOFMANOTES:“Quality Hardwood Lumber and Flooring”P.O. Box 458, Hwy. 41 South Buena Vista, GA 31803Tel: (229) 649-9328 FAX: (229) 649-9585Quality Bandsawn HardwoodsProduce 17 million ft. annually • 500,000’ kiln capacityNewman 282 planer • Straight line rip capabilityExport prep and shipping • Width sorting availableSpecies: Red Oak, White Oak, Ash, PoplarLumber Sales: Roland Weaver 229-649-9328Kevin Cloer 229-649-9328Brad Bradley 706-754-8221“Quality Hardwood Flooring”75,000 SF Manufacturing facility Producing 2 1 /4, 3 1 /4, 4, & 5” FlooringContactKevin Cloer - E-mail: kcloeroakcrest@windstream.netKeith Waldrop - E-mail: tkwaldrop@windstream.netSalem Frame...The Company To Contact For Custom Dry KilnServices or Quality Wood ComponentsFor the best in Custom Dry Kiln Services or QualityWood Components, no one does it better than SalemFrame located in Salem, Virginia. Call us at 540-389-8661 when we can help you.CUSTOM KILN DRYING SERVICESFast turnaround & very competitive pricing • SurfacingSpecializing in pine, oak, & other hardwoodsPre Dryer capacity: 1,000,000 BFDry Kiln capacity: 600,000 BFFor Custom Dry Kiln Services call Darrell Cannaday,Tim Worrell or Gary Wilson at our Virginia facility at540-389-8661, or e-mail us at tim.worrell@rowefurniture.comQUALITY WOOD COMPONENTSCONTACT Eric Collins or Kenneth Cox at our dimensionmill in Salem, Virginia by calling 540-389-8661. Wehave a rough mill, a finish mill, sanding capabilities,CNC routers, etc. that help us to make all types ofwood parts such as furniture legs, blanks, doweling, etc.Salem FrameA location ofRowe Fine Furniture Inc.Loss Leader Sales In A RapidlyChanging IndustryWHAT CAN BE DONE ABOUT ITWhile the tendency for many faced with this sort of adversity isto batten down the hatches and wait for the storm to pass, NOFMAis instead looking to find long-term solutions that can make theindustry and its respective participants stronger when the turnaroundoccurs. There is reason for optimism. Despite the difficulttimes, wood flooring continues to be a popular choice in the marketplaceand recent volume levels are the highest ever recorded forthis industry.In today’s market, unfinished solid wood flooring seems to beparticularly hard hit. Some of that can be blamed on increased competitionfrom imported products, as well as prefinished solid andengineered. We believe some other factors are at play. In an effortto look into that, NOFMA recently hosted a solid unfinished flooringsummit in Nashville, Tenn. Among the topics on the agenda atthat meeting were the potential that rests in revising the standardsto allow for slightly thinner flooring. Can efficiencies be gained bycutting thinner flooring? Can those efficiencies be realizedthroughout the value chain? These and other questions surroundingthis issue were explored.Regardless of the outcome of those discussions, we know for afact that there is no better time than now to be looking at changesin approach, from process improvements to a broadened perspectiveon where our key markets lie. To that end, NOFMA has adopted“Profiting in a Down Market” as the theme for its annual meetbyTIMM LOCKEExecutive Vice PresidentNOFMA: The Wood FlooringManufacturers Assoc.Memphis, Tenn.There’s not much fun to be had in the flooringindustry these days. As of this writing,most manufacturers I’ve spoken with aredeep into survival mode and many are makingsales at significantly below cost, just to keep the dollars flowing.The problems facing the industry are well documented. Housingstarts have slowed to a trickle, down more than 25 percent from ayear ago, while residential building permits are off more than athird. New home completions are down more than 25 percent, andnew home sales are down almost 30 percent. Meanwhile, creditissues combined with weak consumer confidence are causinghomeowners to be more careful about remodeling spending, traditionallya good outlet for wood flooring producers. And, in whatfeels like piling on to those of us in the building products industry,the one shining star, commercial construction, also appears to besuccumbing to the economic slowdown we’re facing domestically.It’s a one, two, three punch that, unfortunately, will not be survivedby all.Please turn to page 7322 Hardwoods...The All-Purpose Material

MERIDIEN HARDWOODS OF PA., INC.(814) 563-4614 FAX: (814) 563-4624Email: meridien@penn.comYard Address: Old Pittsfield Rd., Pittsfield, PA 16340“Everything You’ll Ever Need From The Forest”Shawn, Brandon, Dan and Mike Ferman with 4/4Hard Maple.Lumber stored under T-sheds.Rick Frye, dry kiln superintendent, standing infront of a new dry kiln.• 18 Acre Concentration Yard •• Double End Trimmer...Trim Line (40 Sorts) •• Straight Line Ripping and S2S Facilities •• We Offer Export Preparations, Container Loading, Mixed Species & Thicknesses •• Wholesalers of Northern, Appalachian and Southern Hardwoods •• 800,000’ Dry Storage •• Dry Kiln Capacity 250,000’ •BUILD YOUR OWN LOADAll KD lumber pick-a-pack tallied.Dan Ferman(814) 563-4614Michael Songer(814) 486-1711Brandon Ferman(814) 563-4614Mike Ferman(814) 563-4614

Announcing….the 1st CHINESE EDITIONof theFOREST PRODUCTS EXPORT DIRECTORYThe "Purchasing Guide" for North American Forest Products• 8,000 copies distributed to buyers in CHINA and VIETNAMgoing to these types of firms: Importers/distribution yards,agents, manufacturers of wooden furniture, cabinets, millwork,mouldings, flooring, doors, windows, stairways, toys,novelties, components, mantels, etc., log yards, veneer mills,and plywood plants.• Advertisers listings in CHINESE and ENGLISH(non-advertisers listed in English only)• Non-advertisers may be listed in Chinese and English withboldface print for only $1,000 (must be prepaid: 12 lines max.per listing)Lumber• Published and mailed in late 2008• Special Position rates quoted upon request• Discount rates for current advertisers in other <strong>Miller</strong>publications• Full page Advertisers also receive complimentary “Who’s Who”article in Import/Export Wood Purchasing News (250 wordsmax.)DON’T WAIT!Space reservationdeadline is August 1st!VeneerFull Page Rate: $2,675.001/2 Page Rate: $2,235.00(Color charges additional)Please Call:1-800-844-1280Fax: 901-373-6180PO Box 34908 • Memphis, TN 38134Email: michellep@millerpublishing.comVeneer Logs

CYPRESS1” DIMENSION2” DIMENSIONFINISHSIDINGFENCINGPANEL PECKYTIMBERSRippingPlaning MillMoulderSemi-DimensionResawMEMPHIS, Tennessee 38182-0526 PHONE: (901) 274-6887 FAX: (901) 274-68501279 N. McLEAN, P.O. BOX 820526 WEBSITE: WWW.CYPRESSUSA.COM Email: wlumber@cypressusa.comDISTRIBUTION YARDHARDWOODSFURNITUREMILLWORKINDUSTRIALMOULDINGWHEN YOU MOVE...1. For faster service attach OLD mailing label in space belowIf mailing label is not available, print your old companyname and address in this box.2. Print your NEW mailing address here:Name ______________________________________Title _______________________________________Company ___________________________________Address ____________________________________City________________State________Zip _________3. Mail to: Circulation Dept.<strong>National</strong> Hardwood MagazineP.O. Box 34908, Memphis, TN 38184-0908PHONE 901-372-8280 FAX: 901-373-6180E-MAIL: circ@millerpublishing.com4. Please allow six weeks for change to take effect.P.O. Box 1688Augusta, GA 30903(706) 724-22531-800-241-3370FAX: 1-800-673-3720Charles “Lindy” Markland, Vice-chairman; Bob Moore, Chairman ofthe Board/CEO; and Dave Redmond, President/COOWith Highland?No surprises...just getting it right order after order!We offer fine Appalachian Northern andSouthern Hardwood lumber in most species,green or kiln dried, to customers throughoutNorth America and other countries. Our mainfunction is providing quality lumber with a focuson service and commitment to our customersand suppliers.The relationship we have built with our presentcustomers and suppliers has helped our first 20years of being in business truly enjoyable andrewarding. We are confidently looking forwardto our next 20 years.Hugh PickettSalesRobbie ParrottSalesBrad MerrySalesMike FlemingSalesTyler CarterHighland InternationalMarketing & DevelopmentSingaporeJUNE/2008 25

Holt & Bugbee Expands Sales Force,Targets High-End ProductsBY M.A. WALLACETewksbury, Mass.– Lumber industry entrepreneur John Cutter knew a thing or two aboutinternational networking in 1825 when he supplied a New England ship captain with blocks of ice inexchange for transporting South American Mahogany logs back for rough cutting at Cutter’sCharlestown, Mass., sawmill. Soon after, the company Cutter founded was renamed for his son-in-law,Stephen Holt, and business associate John Bugbee.Company headquarters shifted toTewksbury in 1967 to better serve a growingcustomer base. Holt & Bugbee Co.added a second location in Mt. Braddock,Pa., in 1994 and a third operation inBoyertown, Pa., in 1999.Holt & Bugbee Co. hasconvenient access toNorthern Appalachian Hardwoodsand an ideal location(less than an hour fromPhiladelphia) for serving customersin the mid-Atlanticregion.Fast forward five generationsand many industrychanges and today Holt &Bugbee Co. does businesscoast-to-coast and around theworld. The company keeps 195 employeesbusy through 40-hour weeks at allthree locations, with 135 of the staff locatedin the home office.“Operating as distribution yards withhigh-end millwork services is the bestway for us to fulfill orders from our primarycustomer base,” said Phillip Pierce,Holt & Bugbee’s president. “Timely supplyand delivery of smaller specialtyorders defines the future for us as a distributioncompany in the lumber industry.”Doing business by phone and the❝ Timely supply and deliveryof smaller specialty ordersdefines the future for us as adistribution companyin the lumber industry. ❞Internet is a growing necessity for viablebusinesses. Nevertheless, company presidentPhillip Pierce also maintains face-tofacetransactions continue to be an importantfeature of Holt & Bugbee’s workingoperation. More than half of the company’s22 sales persons conduct businesson-the-road. The company’s domestictrading area includes the New York/NewEngland and Mid-Atlantic areas intoOhio, Pennsylvania, Virginia and WestVirginia. Two of the company’s six lumberbuyers are on the road purchasingrough green timber from sawmillsthroughout the mid-Atlantic. Holt &Bugbee’s web site boasts that the companyoffers some of the finest Cherry lumberin the world.In addition to Cherry, Holt & BugbeePhillip Pierce, President of Holt & Bugbeeoffers a broad array of domesticHardwood species, which include Alder,Ash, Aspen, Basswood, Birch, Butternut,Hickory, Hard and Soft Maple, Red andWhite Oak, Poplar and Walnut.Additionally, the firm offers softwoodspecies that includecypress, eastern whitepine, fir and aromaticcedars.“We purchase fromNew England andAppalachian producers -some of them we havebeen dealing with formany years,” said Pierce.Holt & Bugbee offersthe imported Hardwoodspecies of Spanish Cedar,European Beech, Baltic Birch, Jatoba,African Mahogany, Genuine Mahogany,Sapele, Teak and Utile. “We offer gradesof No. 1 Common and Better in widths of4/4 through 12/4,” said Pierce, who notedconsiderable demand for domesticHardwoods, including White Oak inEurope, Near East and Far East.Approximately 25 million board feet oflumber passes through Holt & Bugbee’sfacilities and distribution yards in a year’stime. Truckload lots are brought to theTewksbury or Mt. Braddock facilities26 Hardwoods...A Renewable Resource

The Delle Vedove catalytic UV primer and profile sander can process up to 20,000 linealfeet per day.Holt & Bugbee Co., headquartered in Tewksbury, Mass., has provided NorthernAppalachian Hardwoods to its customers across the globe for over five generations.The Weinig Raimann rip saw can be programmed to handle up to 10 width sorts.Moulder heads are prepared to run thousands of custom profiles on 8 Weinigmoulders.where the lots are stacked with kiln sticks between eachcourse of lumber and either air dried or kiln-dried in any of15 kilns – nine at the Tewksbury site, six at the Mt. Braddocklocation. Lumber is kiln-dried to six to eight percent moisturecontent. Following inspection, lumber is sorted on an automatedgrading station according to customers’ specifications.Equipment used at the company’s locations includes:Sanborn and Pendu stackers; Sanborn and Reckart gradingstations; Irvington Moore, Kilntec and American Wood Dryerskilns; a SII pre-dryer, Weinig moulders, Pinheiro, Newman andYates planers, Mereen-Johnson, Pinheiro and Weinig Raimann ripsaws, McDonough resaw, Delle Vedove UV primer and profilesander; and Challoner double-end tenoner.Approximately 35 percent of Holt & Bugbee’s lumber is sold askiln-dried rough, with another 65 percent receiving surfacing andAnnually, H&B dries about 20 million board feet through 15 kilns located in the Tewksbury, Mass.and Mt. Braddock, Pa. facilities.ripping at the company’s finishing mills. A great deal of this materialis processed through the moulders into a wide range of products,from bases and casings, chair rails, crown moulding, panelmouldings, picture frames and more. “We have one customer whoturns mouldings into wooden crosses,” Pierce noted. MouldingPlease turn to page 63JUNE/2008 27

Cardwell Lumber Inc.Quality Stays True Through Three GenerationsMembers of the Cardwell family include: Lesa Noe; Jeff Morrow; Marilyn Cardwell; Leroy Cardwell; TonyCardwell; and Mark Cardwell.BY GARY MILLERNovelty, Mo.— From very humble beginnings, Cardwell Lumber Inc. hasgrown to where today they have a sawmill and a stave mill both here and in New London,Mo. The firm also has a Hardwood lumber concentration yard with dry kilns in JeffersonCity, Mo., called Cardwell Hardwoods.The company traces its roots back toWilliam Junior Cardwell, a farmer whopurchased one of the first chainsaws in1952. Leroy Cardwell, Junior’s son andpresent day owner of Cardwell LumberInc., said his father cut his first stave boltsin 1954, and not long after that he starteda sawmill.“During my father’s era in the stave andlumber business, nobody knew what achainsaw was around this part of thecountry,” Leroy said. “Everybody used acrosscut saw. Back then, there wasn’t anygrade lumber purposely made at my dad’ssawmill operation. Everything was justcut to various farmers’ orders for fences,barns or whatever they needed.”Staves, which are individual wood stripsthat form the sides of barrels, were mainlycut from the bottoms of trees, leaving agood portion of the log unused. By 1958,Junior Cardwell decided to establish asawmill that would process into lumbermost of each log his company obtained.“I think dad paid $250 for his firstsawmill,” Leroy said. “My father, hisneighbor, Chuck Hicks, and I ran thesawmill. Several years later, Hicks and Ibought the sawmill from dad and I gavehim $250 for it. My father is one of thefew people in the lumber industry that Iknow that never lost any money in thesawmill business.”Cardwell and Hicks relocated the millfrom his father’s property, and leased theland in Novelty, Mo., where CardwellLumber Inc. is situated today. Both menrenamed the company C & H ForestProducts, and they operated a manualCorley mill. The firm continued to grow,adding 12 employees and one deliverytruck.However, in 1969, Hicks decided to sellhis part of the company to LeroyCardwell. “I incorporated my sawmillbusiness in 1973, and it’s been calledCardwell Lumber Inc. ever since,” hesaid.Today, Cardwell Lumber Inc. has morethan 100 employees counting all three ofits locations, and it is indeed a familyenterprise.Leroy said he no longer tackles physicalwork at his company, but he still overseesday-to-day operations at his stave mill andsawmill facilities. He continues to sellstaves to repeat customers. “I am the onewho signs my name to the note wheneverwe need to buy more things around here,whether it be new equipment, land ormaterials to construct another buildinghere,” Leroy explained.Mark Cardwell, one of Leroy’s sons,handles green lumber sales and managesthe Novelty location. In addition, hePlease turn to page 6128 Hardwoods Have Workability

Johnny Craggs handles shipping and helps load trucks.Joe Shahan is the mill manager at Cardwell Lumber Inc.’s New London, Mo.,operation.This large Appalachian log is being manufactured into lumber bya 62-inch McDonough band mill with a Corley carriage.Leland Klocke operates the log loaders and manages the log yard for Cardwell Lumber Inc.’s Novelty, Mo.,facility.This is a view of the green chain at Cardwell Lumber Inc.’s Novelty, Mo., sawmill operation.At Cardwell Hardwoods’ lumberyard with dry kilns in Jefferson City, Mo.,their Hardwood lumber is sold on the wholesale and retail level. These lumberracks hold different species of Appalachian Hardwood lumber for the retailside of their business.This is a view of the office building at Cardwell Hardwoods’ Jefferson City, Mo., Hardwood lumberconcentration yard.JUNE/2008 29

New Facility Brings Growth ForBingamanBY PAUL MILLER JR.Clarendon, Pa.— The rapid growth of the lumberyard here sinceBingaman & Son Lumber Inc. purchased it in 1994 has surprised many at thecompany.Some 15 years ago, the facility, then owned by BruceDunn of W.B. Dunn Lumber Co., had just four employees,a kiln drying capacity of 75,000 board feet and a lumberinventory of 300,000 board feet. Maurice Bennett, generalmanager of the Clarendon Division, said workers did mostlumber handling by hand.Bennett said Max Bingaman, owner of Bingaman & Son,had no room to expand operations at the firm’s other lumberyardin Kreamer, Pa., when Dunn decided to sell hisplant. “Max had been buying quality kiln-dried Cherry,Hard Maple and Red Oak from Bruce for over 25 years, andwanted to retain this supply of lumber for his customers,”he said. “Plus, it was in a good geographic location. It wasjust a natural fit.”Bennett added, “One of the reasons that Max was interestedin buying this yard is because it is located in theAllegheny <strong>National</strong> Forest, which has the finest BlackCherry available anywhere in the world. Because of the climatein northwestern Pennsylvania and southwestern NewYork, the color of the Hard Maple in this region is desiredby our customer base.”Today, the 12-acre facility has 42 employees on twoshifts, and boasts a kiln drying capacity of 420,000 boardfeet per charge, thanks to the addition of six AmericanWood Dryers dry kilns. Other additions to the Clarendonyard include automated grading and stacking operations,and a dry line.Bingaman & Son also utilizes a 240,000-board-foot fandrying shed during the summer months in Clarendon tomaintain excellent color in white woods such as Hard andSoft Maple. Scott Shaffer, vice president of yard operations,said, “The lumber is in the shed for about eight days, andthen goes directly into the dry kilns. It helps us dry Hardand Soft Maple much whiter than we could without it.”Please turn to page 58Key executives at Bingaman & Son Lumber Inc. include Chris Bingaman, vice president of sales and marketing; Dean Heintzelman, executive vice president; and MaxBingaman, president.30 Hardwoods Have Resiliency

Maurice Bennett is general manager of the Clarendon Division.Bingaman & Son has a 240,000-board-foot fan drying shed to maintain excellentcolor in white woods during the summer months.Lumber inspector Michael Brant helps maintain the quality of Bingaman & Son’sAppalachian Hardwoods.Three of the Bingaman & Son’s dry kilns are pictured. The Clarendon locationboasts over 3 million board feet of kiln- and air-dried lumber inventory.The company recently added a 30,500-square-foot steel building to install a green lineand sticking line.JUNE/2008 31

KFIA Celebrates Service To IndustryBY GARY MILLERCovington, Ky.– Thethree-day annual meeting of the Kentucky ForestIndustries Association (KFIA) was recently held hereat the Radisson Cincinnati Riverfront.Among the presentations was a keynote address byTom Inman, president of Appalachian HardwoodManufacturers, Inc. (AHMI), who discussed theAppalachian Hardwood Verified Sustainable program.AHMI introduced the campaign in 2007 thatutilizes U.S. Forest Service Forest InventoryAssessment data to verify that the AHMI territory issustainable.He said the AHMI boundary includes 344 countiesin 12 states in the eastern U.S. and USFS data showsgrowth to removal at 2.29 to 1. The research proves2.29 cubic feet of Hardwood lumber growth is occur-Grant Willnow, U•C Coatings Corp., Buffalo, N.Y.; Pete Green, Beard Hardwoods, Moss, Tenn.;Brandon Koetter, Koetter Woodworking Inc., Borden, Ind.; and Mike Ray, U•C Coatings Corp.Please turn to page 58Toto Robinson and Jack Grace, Robinson Lumber Co., New Orleans, La.Larry Randall, Better Built Dry Kilns Inc., Villa Hills, Ky.; Toto Robinson, RobinsonLumber Co., New Orleans, La.; and Alex Lewin and Chris Randall, Better Built DryKilns Inc.Danny and Rebekah Arnold, Little River Lumber Co. LLC, Hickory, N.C.; SteveParker, Woodcraft Industries, Bowling Green, Ky.; and Robert Elwell Jr., WoodcraftIndustries, Greenville, Pa.Dennis Rayber, Tiger Wood Co., Dundee, Ohio; Marty Cope, Associated HardwoodsInc., Granite Falls, N.C.; Frank Colyer, Tiger Wood Co.; and Larry Johnson and ClarkBoyer, Pine Mountain Hardwood Lumber Co., Whitesburg, Ky.(Editor’s Note: In conjunction with the KFIA meeting, a hospitality suite was hosted by Robinson Lumber Co., New Orleans, La., andVan Meter Insurance, Bowling Green, Ky. The first seven photos accompanying this article were captured at the hospitality suite.)32 Hardwoods...The All-Purpose Material

Casey and Tony Goodman, C.B. Goodman & Sons Lumber Inc., Hickory, Ky.; MikeThomas, TS Manufacturing, Milton, Fla.; and Troy Jamieson, Somerset Wood ProductsInc., Somerset, Ky.Gary <strong>Miller</strong>, <strong>National</strong> Hardwood Magazine, Memphis, Tenn.; Mike White, HaroldWhite Lumber Inc., Morehead, Ky.; and Tom Imm, Pine Mountain Hardwood LumberCo., Whitesburg, Ky.Jim Burris, Fred Boeninger and Ken Morris, Corley Manufacturing Co., Chattanooga,Tenn.Kevin Corder, AWMV Industrial Wood Products, Indianapolis, Ind.; and Gary Moore,Wood-Mizer Blades, Indianapolis, Ind.Rob McCarthy, Industrial Timber & Lumber Corp., Beachwood, Ohio; CrystalOldham, Hardwood Forest Foundation, Memphis, Tenn.; and Skip Holmes, Thomas &Proetz Lumber Co., St. Louis, Mo.Thom Brown, SII Dry Kilns, Lexington, N.C.Dennis Davis, Diamond Forest Resources, Morehead, Ky.; Dennis Adkins, ClearcreekHardwoods, Grayson, Ky.; and Wendell McClurg, Diamond Forest Resources,Clearfield, Ky.Sharon Gilpatrick, Pennsylvania Lumbermens Mutual Insurance Co., Philadelphia,Pa.; and Richard Pumphrey, Pennsylvania Lumbermens Mutual Insurance Co., OliverSprings, Tenn.Ray Shepard, Oaks Unlimited, Waynesville, N.C.; Ken Jacobson, Uniwood Inc.,Greensboro, N.C.; Whit Whitmire, USNR, Waynesville, N.C.; and Dale Bradicich,USNR, Salvisa, Ky.Bob Zandi, Baillie Lumber Co., Leitchfield, Ky.; Monte Pope, ISK Biocides Inc.,Memphis, Tenn.; Welby and Lee Neal, Neal Lumber Co., Albany, Ky.; and JoeClendenin, Baillie Lumber Co.Additional photos on page 50JUNE/2008 33

Thousands Flock To NWFA ExpoFort Lauderdale, Fla. –The NWFA’s 2008 Education Conference and WoodFlooring Expo was held here recently. The showattracted just over 3,400 attendees from throughoutthe world, with 307 companies filling 577 exhibitbooths.NWFA executive director and chief executive officer,Ed Korczak, said that attendance at the show wasdown slightly from last year, which was expecteddue to the downturn in the wood flooring industry.“Although the industry is down between 15 to 20percent, we were pleasantly surprised that our attendancethis year was down less than 100 people from2007,” said Korczak. “In fact, the entire focus of theeducation conference focused on surviving in a downmarket. Those companies who can make the adjustmentsnow to survive the downturn will be wellpoised when the industry turns around.”On the trade show floor, demonstrations includedMoisture Barriers, Unique Finishes, Stairs &Please turn to page 56BY GARY MILLERDavid and Erin Graf, Graf Bros. Flooring Inc., South Shore, Ky.; Beth Burton, Canterbury Flooring,Mocksville, N.C.; and Tom Worrell, E.C.F. Supply, Miami, Fla.Scott Rossi, American Hardwood Industries, Cromwell, Conn.; Diane Beauchamp,Northern Hardwoods, South Range, Mich.; Roger Barber, Graham Lumber Co.,Linden, Tenn.; and Randy Flament, Emporium Hardwoods Inc., Emporium, Pa.Mike Gurley, Taylor Lumber Inc., McDermott, Ohio; Scott Taylor, MacGregor GroupLLC, Milwaukee, Wis.; and Terri Lemon and Tom Graf, Taylor Lumber Inc.Randy Akers, Steven Gutsch, Gary Zander, Woody Phelps, Gary Ort, Todd Braun, RobQuilliam, and Nick Larson, Aacer Flooring LLC, Peshtigo, Wis.Diane Pevy, Amy Rineck and Damon Graf, Shamrock Plank Flooring, Memphis, Tenn.34 Hardwoods Have Versatility

Don Meyer, Baillie Lumber Co., Hamburg, N.Y.; and Don Conner, Mullican Flooring,Johnson City, Tenn.Jim Fikes, Linda Wright and Bill Buchanan, Buchanan Hardwood Flooring Co. LLC,Aliceville, Ala.Tim Elbers, Progressive Solutions Inc., Reese, Mich.Warren Spradlin and Jason Delves, BLC Hardwood Flooring, Macon, Ga.; and Craig<strong>Miller</strong>, Battle Lumber Co. Inc., Wadley, Ga.John Clark, Kitchens Bros. Manufacturing Co., Hazlehurst, Miss.; Michael Snow,AHEC, Washington, D.C.; and Gary <strong>Miller</strong>, <strong>National</strong> Hardwood Magazine, Memphis,Tenn.Terry Pate, Dean Hardwoods Inc., Leland, N.C.; Eli Uminer, One of A Kind Flooring,Brookhaven, N.Y.; and Chad Smith and Chuck Dean, Dean Hardwoods Inc.Keith Hovey and Ronald Hendricks, Springcreek Flooring by North Pacific, WestPlains, Mo.Steve Bunch and Darwin Murray, Springcreek Flooring by North Pacific, West Plains,Mo.Jaime Flynn and Rick Barrett, Midwest Hardwood Corp., Maple Grove, Minn.Bobby Cloer, Brad Bradley, Kevin Cloer, and Roland Weaver, Oakcrest Lumber &Flooring, Buena Vista, Ga.Additional photos on next pageJUNE/2008 35

NWFA PHOTOS - ContinuedHugh Overmyer and Pat Philen, AHI Linden Lumber LLC, Linden, Ala.Mick Paul, Austwood Australia PTY Ltd., Tamworth, Australia; Mark Hayes,Weyerhaeuser, Federal Way, Wash.; and Gary Janelle, Weyerhaeuser, St. Matthews,S.C.Ken Hillemeier and Bruce Rafferty, Rex Lumber Co. Inc., South Windsor, Conn.; andRalph Bartles, Graf Bros. Flooring, South Shore, Ky.Richard Hook and Dino Bettamin, B.C. Hardwood Floor Co. Ltd., Vancouver, B.C.; andRick Goodin, Lebanon Oak Flooring Co., Lebanon, Ky.John Troendle, Crescent Hardwood Supply, Harahan, La.; and Tom McMillan, SteveStoufflet and Toto Robinson, Robinson Lumber & Flooring, New Orleans, La.Wayne Daniel and Rose Mary Laster, Maxwell Hardwood Flooring Inc., Monticello,Ark.Keith Cudmore, Metropolitan Hardwood Floors Inc., Kent, Wash.; Dick Hedrick and,Keith Waldrop, Somerset Hardwood Flooring, Somerset, Ky.; Tom Gormley, Advent-Guard Inc., Laval, Que.; and Harry Baker, Somerset Hardwood FlooringShayne Lachlan and Bob Engwirda, Moxon Timbers Inc., Winchester, Va.; Phil Nolin,Moxon Timbers Inc., Portland, Ore.; and Tony Moxon, Moxon Timbers Inc.,Winchester, Va.Gary Ort, Ted Lander and Rick Smrcka, Wolf River Lumber Inc., New London, Wis.Tim Finger, Great Lakes Custom Tool Manufacturing Inc., Peshtigo, Wis.; and JackShannon, J.T. Shannon Lumber Co./Shamrock Plank Flooring, Memphis, Tenn.36 Hardwoods...A Renewable Resource

NWFA PHOTOS - ContinuedGene Barnes and Phil Barnes, Barnes Bros. Hardwood Flooring, Hamburg, Ark.Richard Davis Jr. and Richard Davis, Caribbean Wood Products International,Savannah, Ga.Jim Duke, Chickasaw Brand Hardwood Flooring, Memphis, Tenn.Timm Locke, NWFA, Memphis, Tenn.; Keith Price, Northland Corp., Lexington, Tenn.;and Steve Stoufflet, Robinson Lumber & Flooring., New Orleans, La.William Parsons, Appalachian Lumber Co., Wilkesboro, N.C.; Josh Ellis and JudyHaines, Wood Plus Hardwood Flooring LLC, Galax, Va.; and Scotty Roten and WilliamChurch, Appalachian Lumber Co.Mike and Diana Gurley, Taylor Lumber Inc., McDermott, Ohio; Denny Morrow, BlackDiamond Stoneworks, San Clemente, Calif.; and Jean and Ron Vastine, Taylor LumberInc.Ray Shouman, Home Renovation Guide, Toronto, Ont.; and Dave Kazmierczak, GreatLake Veneers Inc., Marion, Wis.Brian Greenwell and Tressa Samdal, Mullican Flooring, Johnson City, Tenn.; MikeKnight, Mullican Flooring, Pawleys Island, S.C.; Rick Burchfield, Mullican Flooring,Norton, Va.; and Neil Winger, Mullican Flooring, Philadelphia, Pa.P.J. Hart and Grace Terpstra, Hardwood Federation, Washington, D.C.; and NickGeorgelis, Weaber Inc., Lebanon, Pa.Additional photos on page 51Griffin Augustin and Kevin Westerhaug, Kootenay Innovative Wood Ltd., Castlegar,B.C.JUNE/2008 37

Penn-Sylvan Hosts Penn-YorkBY PAUL MILLER JR.Titusville, Pa.—Over 170 members of the Penn-YorkLumbermen’s Club recently attendeda meeting at the Cross Creek Resorthere. Penn-Sylvan International Inc.,headquartered in Spartansburg, Pa.,hosted the event, which includedcocktails and dinner.Wayne Koble, senior vice presidentand director of investments for PNCWealth Management, served as thekeynote speaker. Koble discussed theeconomy and investments.Officers serving the second of twoyearterms include Randy Flament,Emporium Hardwoods, president;Jay Reese, Penn-Sylvan InternationalInc., vice president; and Tom Johel,U•C Coatings Corp., secretary-treasurer.Guests were also allowed theopportunity to clay hunt. A golf tournamentat the resort wrapped up theevent. Jay Reese, who shot a 77, finishedwith the lowest gross, andMaury Bennett, who shot an 80 forthe day, finished with the secondPlease turn to page 55Marc Reese, Salem Hardwood Inc., Adamsville, Pa.; and Bill, Marie, Mike, Mitra and Jay Reese, Penn-Sylvan InternationalInc., Spartansburg, Pa.Jay Reese, Penn-Sylvan International Inc., Spartansburg, Pa.; Randy Flament,Emporium Hardwoods Inc., Emporium, Pa.; and Tom Johel, U•C Coatings Corp.,Buffalo, N.Y.Bill Reese, Penn-Sylvan International Inc., Spartansburg, Pa.; Michael Drusinsky,Industrial Timber & Lumber Corp., Beachwood, Ohio; and Jerry Puckley, SylvanHardwoods, Waterford, Pa.38 Hardwoods Have Workability

Eric Porter, Abenaki Timber Corp., Kingston, N.H.; Mike Reese, Penn-SylvanInternational Inc., Spartansburg, Pa.; Gary Hart, Colonial Millwork Ltd., Beverly,W.Va.; and Chuck Ward, Coastal Lumber Co., Buckhannon, W.Va.Greg and Julie Beers, Penn-Sylvan International Inc., Spartansburg, Pa.Marie Reese, Penn-Sylvan International Inc., Spartansburg, Pa.; Brandon Ferman,Meridien Hardwoods of PA Inc., Pittsfield, Pa.; Karen Burrow, Penn-SylvanInternational Inc.; Jean Desilets, C.A. Spencer Inc., Laval, Que.; and Mitra Reese,Penn-Sylvan International Inc.Brian Walsh, Cherry Forest Products, Guelph, Ont.; Mike Bartlett, Wesont LumberCo. Ltd., Burlington, Ont.; Gordon McIlvain, Alan McIlvain Co., Marcus Hook, Pa.;Larry and Ian Fulton, Fulton Forest Products, Shippenville, Pa.; and Dan Brownlee,Brownlee Lumber Inc., Brookville, Pa.Ron Jones, Ron Jones Hardwood Sales Inc., Union City, Pa.; and Chris Snow and ChadMartin, PNC Bank, Erie, Pa.Chris Austin and Vicki Ferri, Satin Finish/Erie Flooring, West Lorne, Ont.; and TedRowe, Aurora Timberland, Bradford, Ont.Rod Bedow and Keysha Shafer, Blue Ox Lumber Co., Titusville, Pa.; and Milo Glancy,Ron Jones Hardwood Sales Inc., Union City, Pa.Additional photos on page 53Terry Hunter, Taylor-Ramsey Corp., Lynchburg, Va.; Scott Holley, Industrial Timber& Lumber Corp., Beachwood, Ohio; Marc Reese, Salem Hardwood Inc., Adamsville,Pa.; and Roger Feltner, Taylor-Ramsey Corp.JUNE/2008 39

Southwestern MembersMeet In VidaliaVidalia, La.— More than 100members and guests of the Southwestern HardwoodManufacturers Club recently met here for a meetingand dinner at the upscale Comfort Suites hotel.The annual crawfish boil was hosted by Terry andBruce Reynolds of Rives & Reynolds Lumber Co.,Louisville and Natchez, Miss.; John Jones of WardTimber Ltd., Linden, Texas; and Bobby Noland ofNoland Lumber Co., Gordo, Ala. Those attendingenjoyed eating the delicious boiled crawfish, potatoes,hush puppies and corn on the cob or steaks withall the trimmings.The round table discussion prior to the dinnerallowed club members to give their thoughts aboutcurrent business conditions and insight for the future.Attendees received plenty of information about thelumber markets in Arkansas, Tennessee, Louisiana,Texas, Alabama and Mississippi.One sawmill owner said flooring manufacturers andsawmills are losing money on flooring and lumberrespectively.“The information we received was not encouraging,but it was a great party,” he said. “We’re all lookingfor the Hardwood market to improve when the housingmarket gets better.”•PHOTOS BY MARK COFFEYToto Robinson, Robinson Lumber Co. Inc., New Orleans, La.; J.R. Johns, Armstrong Flooring,Jackson, Tenn.; Leigh Ann and Kirby Field, Kitchens Bros. Mfg. Co. Inc., Hazlehurst, Miss.; and RonnyCornelius, Steel City Lumber Co., Middleton, Tenn.Kim and Milton Garrett and William Browning, J.M. Jones Lumber Co. Inc., Natchez,Miss.Coby Crager, Al-Tom Forest Products Inc., Waynesboro, Miss.; Don Woodruff andRobert Taylor, Taylor Machine Works Inc., Louisville, Miss.; and Jerry Kelley, Al-TomForest Products Inc.Mike Parker, Anderson-Tully Co., Vicksburg, Miss.; Pete Johnson, Taylor MachineWorks Inc., Louisville, Miss.; and Roy James, Anderson-Tully Co.Jerry Hendrix, Ward Timber Co., Linden, Texas; Charlie Netterville, Fred NettervilleLumber Co. Inc., Woodville, Miss.; Leslie Rutland, Rutland Lumber Co. Inc., Collins,Miss.; and Jan Netterville, Fred Netterville Lumber Co. Inc.40 Hardwoods Have Resiliency

James Chadwick, Chadwick Timber Co., Silas, Ala.; Ricky Smith, Kelwood ProductsInc., Enterprise, Miss.; Alfred Loeg, Loeg Lumber Co., Slocum, Ala.; and Wood Holley,Wood Holley Lumber Co., Nanafalia, Ala.(Seated) Russell and John Kelly, PJ Lumber Co., Mobile, Ala.; (Standing) Jeff Kelly, PJLumber Co.; Jeff Cowley, USNR, Jacksonville, Fla.; Scott Wesberry, Fred NettervilleLumber Co. Inc., Woodville, Miss.; Jeff Lewis, Lewis Brothers Lumber Co. Inc.,Aliceville, Ala.; and Lynn Lamb, Hatchie River Lumber Co. Inc., Pocahontas, Tenn.Jimmy Hunt, Industrial Timber Inc., Spartanburg, S.C.; Ronnie Cornelius, Steel CityLumber Co., Middleton, Tenn.; and Mike Thomas, T.S. Manufacturing Co., Milton, Fla.Larry and Katy Wright, Hassell & Hughes Lumber Co. Inc., Collinwood, Tenn.; JerryBeauchamp and Angie Wisner, Fred Netterville Lumber Co. Inc., Woodville, Miss.Huntley Gooch, Anderson-Tully Co., Vicksburg, Miss.; Rob Young, Cole HardwoodInc., Logansport, Ind.; and Arnie Hogue, John and Amy Scott, Anderson-Tully Co.John Hamaker, Armstrong Wood Products, Warren, Ark.; and Mike Prisock and DonDavis, Rives & Reynolds Lumber Co. Inc., Natchez, Miss.Duncan Ferguson, Sawmill MD, Crestview, Fla.; William Browning, J.M. JonesLumber Co. Inc., Natchez, Miss.; Tommy Kelley, Al-Tom Forest Products Inc.,Waynesboro, Miss.; and George Prince, Rives & Reynolds Lumber Co. Inc., Natchez,Miss.Stan Morgan, Anderson-Tully Co., Vicksburg, Miss.; Colby Stewart, Main Street ForestProducts, Daphne, Ala.; and John Jones and Jerry Hendrix, Ward Timber Co. Inc.,Linden, TexasJUNE/2008 41

RALPH TAYLOR L5100 Sanderlin Ave., Suite 15100 Sanderlin Ave., Suite 16A Corley 17-degree slanted headrig with a Tyrone-Berry shotgun drive carriageis one of the newest additions at the sawmill.5/4 White Oak being graded on the green chain.Adam Taylor is standing in front of the company’s recentlyinstalled 80,000-board-foot capacity dry kiln in Clarendon,Ark.Tracy Herald Jeff Taylor Ralph TaylorFACILITIES:• 7’ band mill and resaw producing 20,000,000’ of lumber• Tie mill producing an additional 5,000,000’ of lumber• 4,000,000’ covered air drying capacity for Common & Better Red and WhiteOak lumber• 400,000’ fan shed capacity used only for soft Hardwoods• 400,000’ dry kiln capacity• 2,000,000’ dry storage capacity• manufacturing lumber, crossties & boardroad901-684-1400 FAEmail: RtlumbeEmail: Rtlumbe

LUMBER CO. INC.ite 1600, Memphis, TN 38117ite 1600, Memphis, TN 38117FAS Red Oak (right) and 1 Common Red Oak (left) stored in1.5 million BF dry storage facility and ready for promptshipment.All containers and trucks are loaded under cover.or Phil Taylor Adam Taylor Howell Cox(208-983-0977)John Taylor, Vice President and Mark Bueker, GeneralManager standing in front of a partial view of 1 Common &Better Red and White Oak under covered air drying sheds.LUMBER:• Red and White Oak• Ash• Cottonwood• Gum• Hackberry• Elm• Pecan• Sycamore• HickoryCelebrating our 41st year!AX: 901-684-1404umber@aol.comumber@aol.com