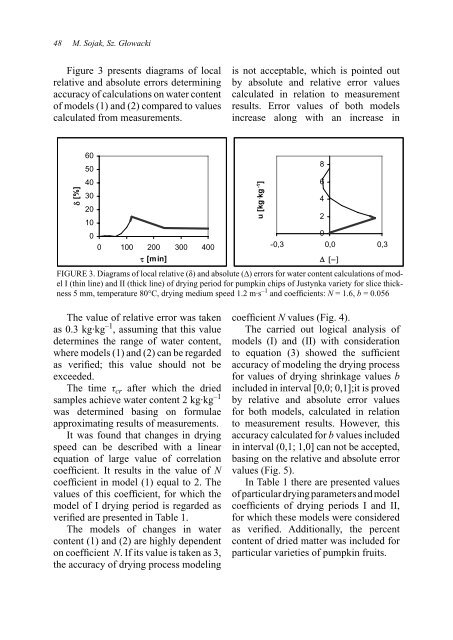

48 M. Sojak, Sz. GłowackiFigure 3 presents diagrams <strong>of</strong> localrelative and absolute errors determiningaccuracy <strong>of</strong> calculations on water content<strong>of</strong> models (1) and (2) compared to valuescalculated from measurements.is not acceptable, which is pointed outby absolute and relative error valuescalculated in relation to measurementresults. Error values <strong>of</strong> both modelsincrease along with an increase inδ [%]60504030201000 100 200 300 4000-0,3 0,0 0,3τ [min]Δ [−]FIGURE 3. Diagrams <strong>of</strong> local relative (δ) and absolute (∆) errors for water content calculations <strong>of</strong> modelI (thin line) and II (thick line) <strong>of</strong> drying period for pumpkin chips <strong>of</strong> Justynka variety for slice thickness5 mm, temperature 80°C, drying medium speed 1.2 m·s –1 and coefficients: N = 1.6, b = 0.056u [kg . kg -1 ]8642The value <strong>of</strong> relative error was takenas 0.3 kg·kg –1 , assuming that this valuedetermines the range <strong>of</strong> water content,where models (1) and (2) can be regardedas verified; this value should not beexceeded.The time τ cr after which the driedsamples achieve water content 2 kg·kg –1was determined basing on formulaeapproximating results <strong>of</strong> measurements.It was found that changes in dryingspeed can be described with a linearequation <strong>of</strong> large value <strong>of</strong> correlationcoefficient. It results in the value <strong>of</strong> Ncoefficient in model (1) equal to 2. Thevalues <strong>of</strong> this coefficient, for which themodel <strong>of</strong> I drying period is regarded asverified are presented in Table 1.The models <strong>of</strong> changes in watercontent (1) and (2) are highly dependenton coefficient N. If its value is taken as 3,the accuracy <strong>of</strong> drying process modelingcoefficient N values (Fig. 4).The carried out logical analysis <strong>of</strong>models (I) and (II) with considerationto equation (3) showed the sufficientaccuracy <strong>of</strong> modeling the drying processfor values <strong>of</strong> drying shrinkage values bincluded in interval [0,0; 0,1];it is provedby relative and absolute error valuesfor both models, calculated in relationto measurement results. However, thisaccuracy calculated for b values includedin interval (0,1; 1,0] can not be accepted,basing on the relative and absolute errorvalues (Fig. 5).In Table 1 there are presented values<strong>of</strong> particular drying parameters and modelcoefficients <strong>of</strong> drying periods I and II,for which these models were consideredas verified. Additionally, the percentcontent <strong>of</strong> dried matter was included forparticular varieties <strong>of</strong> pumpkin fruits.

Investigations on drying <strong>of</strong> new pumpkin varieties 49TABLE 1. Values <strong>of</strong> parameters <strong>of</strong> pumpkin chips drying for which models (1) and (2) were verifiedVarietyParametersJustynka Amazonka AmbarThickness [mm]5 10 5 10 5 10u 0 [kg⋅kg –1 ] 7.63 7.63 7.32 7.32 5.01 5.01τ cr [min] 113 177 125 207 75 147u cr [kg⋅kg –1 ] 1.8 2.1 2.0 1.8 2.0 2.0N 1.60 2.40 1.40 2.80 2.60 1.10k [min –1 ] 0.063 0.043 0.049 0.038 0.052 0.021b 0.056 0.056 0.056 0.056 0.056 0.056u e [kg⋅kg –1 ] 0.020 0.040 0.110 0.040 0.060 0.160K [min –1 ] 0.0222 0.0107 0.0192 0.0098 0.0161 0.0110M s [%] 11.59 11.59 12.02 12.02 16.65 16.65δ [%]N=1,6N=3,0N=5,060504030201000 100 200 300 400τ [min]u [ kg . kg -1 ]N=1,6N=3,0N=5,086420-0,6 -0,3 0,0 0,3 0,6Δ [-]FIGURE 4. Diagrams <strong>of</strong> local relative (δ) and absolute (∆) errors for water content calculations <strong>of</strong>model I (thin line) and II (thick line) <strong>of</strong> drying period for pumpkin chips <strong>of</strong> Justynka variety for slicethickness 5 mm, temperature 80°C, drying medium speed 1.2 m·s –1 and coefficients: N = 1.6, 3.0, 5.0;b = 0.056b=0,056b=0,1b=0,3b=0,056b=0,1b=0,3δ [%]60504030201000 100 200 300 400τ [min]u [kg . kg -1 ]86420-0,6 -0,3 0,0 0,3 0,6Δ [-]FIGURE 5. Diagrams <strong>of</strong> local relative (δ) and absolute (∆) errors for water content calculations <strong>of</strong> modelI (thin line) and II (thick line) <strong>of</strong> drying period for pumpkin chips <strong>of</strong> Justynka variety for slice thickness5 mm, temperature 80°C, drying medium speed 1.2 m·s –1 and coefficients: N = 1.6, b = 0.056, 0.1, 0.3

- Page 1: Annalsof WarsawUniversityof LifeSci

- Page 7 and 8: Inveatigations on soil conservation

- Page 9 and 10: Inveatigations on soil conservation

- Page 11 and 12: Inveatigations on soil conservation

- Page 13 and 14: Annals of Warsaw University of Life

- Page 15 and 16: Precision and energy parameters of

- Page 17 and 18: Precision and energy parameters of

- Page 19 and 20: Precision and energy parameters of

- Page 21: Precision and energy parameters of

- Page 24 and 25: 24 A. Lisowski et al.62.8, 59.4 and

- Page 26 and 27: 26 A. Lisowski et al.TABLE 2. Param

- Page 28 and 29: 28 A. Lisowski et al.in three and t

- Page 30 and 31: 30 A. Lisowski et al.według normy

- Page 33: Economic effi ciency of growing and

- Page 36 and 37: 36 J. Jánský, I. ŽivělováTABLE

- Page 39 and 40: Annals of Warsaw University of Life

- Page 41 and 42: Effect of storage conditions on bio

- Page 43 and 44: Effect of storage conditions on bio

- Page 45 and 46: Annals of Warsaw University of Life

- Page 47: Investigations on drying of new pum

- Page 51 and 52: Annals of Warsaw University of Life

- Page 53 and 54: Analysis of optimal values of air s

- Page 55 and 56: Analysis of optimal values of air s

- Page 57: Analysis of optimal values of air s

- Page 60 and 61: 60 M. Klimkiewicz- units and parts

- Page 62 and 63: 62 M. Klimkiewiczwhere: S(x l,…,

- Page 64 and 65: 64 M. KlimkiewiczTABLE 5. Matrix of

- Page 67 and 68: Annals of Warsaw University of Life

- Page 69 and 70: Properties and structure of spheroi

- Page 71: Properties and structure of spheroi

- Page 74 and 75: 74 G. Elmasry, N. Wang, C. Vigneaul

- Page 76 and 77: 76 G. Elmasry, N. Wang, C. Vigneaul

- Page 78 and 79: 78 G. Elmasry, N. Wang, C. Vigneaul

- Page 81 and 82: Annals of Warsaw University of Life

- Page 83 and 84: Hyperspectral imaging for chilling

- Page 85 and 86: Hyperspectral imaging for chilling

- Page 87 and 88: Hyperspectral imaging for chilling

- Page 89 and 90: Annals of Warsaw University of Life

- Page 91 and 92: Experimental verifying of mathemati

- Page 93: Experimental verifying of mathemati

- Page 96 and 97: 96 J. Kára, Z. Pastorek, R. Adamov

- Page 98 and 99:

98 J. Kára, Z. Pastorek, R. Adamov

- Page 100 and 101:

100 J. Kára, Z. Pastorek, R. Adamo

- Page 103 and 104:

Annals of Warsaw University of Life

- Page 105 and 106:

New fermentation source in the tech

- Page 107 and 108:

Annals of Warsaw University of Life

- Page 109 and 110:

Agricultural business extension aid

- Page 111 and 112:

Agricultural business extension aid

- Page 113 and 114:

Agricultural business extension aid