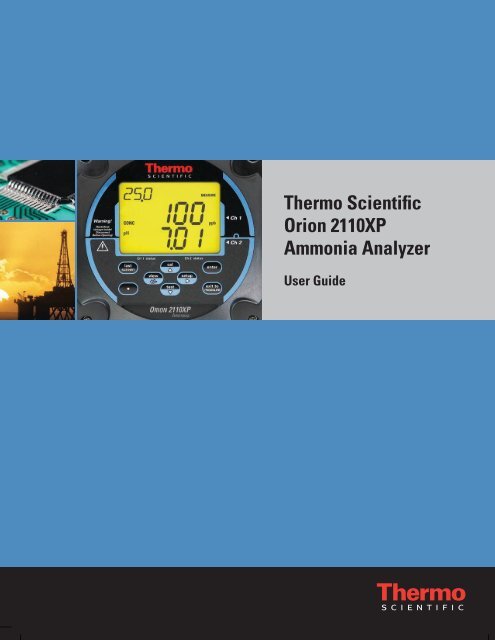

Thermo Scientific Orion 2110XP Ammonia Analyzer

Thermo Scientific Orion 2110XP Ammonia Analyzer

Thermo Scientific Orion 2110XP Ammonia Analyzer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Thermo</strong> <strong>Scientific</strong><strong>Orion</strong> <strong>2110XP</strong><strong>Ammonia</strong> <strong>Analyzer</strong>User Guide

ROSS and the COIL trade dress are trademarks of <strong>Thermo</strong> Fisher <strong>Scientific</strong> Inc. U.S. patent 6,793,787.AQUAfast, Cahn, ionplus, KNIpHE, No Cal, ORION, perpHect, PerpHecT, PerpHecTion, pHISA, pHuture, Pure Water, Sage, Sensing the Future, SensorLink,ROSS, ROSS Ultra, Sure-Flow, Titrator PLUS and TURBO2 are registered trademarks of <strong>Thermo</strong> Fisher.1-888-pHAX-ION, A+, All in One, Aplus, AQUAsnap, AssuredAccuracy, AUTO-BAR, AUTO-CAL, AUTO DISPENSER, Auto-ID, AUTO-LOG, AUTO-READ,AUTO-STIR, Auto-Test, BOD AutoEZ, Cable-Free, CERTI-CAL, CISA, DataCOLLECT, DataPLUS, digital LogR, DirectCal, DuraProbe, Environmental ProductAuthority, Extra Easy/Extra Value, FAST QC, GAP, GLPcal, GLPcheck, GLPdoc, ISEasy, KAP, LabConnect, LogR, Low Maintenance Triode, Minimum StirRequirement, MSR, NISS, One-Touch, One-Touch Calibration, One-Touch Measurement, Optimum Results, <strong>Orion</strong> Star, Pentrode, pHuture MMS, pHuturePentrode, pHuture Quatrode, pHuture Triode, Quatrode, QuiKcheK, rf link, ROSS Resolution, SAOB, SMART AVERAGING, Smart CheK, SMART STABILITY,Stacked, Star Navigator 21, Stat Face, The Enhanced Lab, ThermaSense, Triode, TRIUMpH, Unbreakable pH, Universal Access are trademarks of<strong>Thermo</strong> Fisher.Guaranteed Success and The Technical Edge are service marks of <strong>Thermo</strong> Fisher.PerpHecT meters are protected by U.S. patent 6,168,707.PerpHecT ROSS electrodes are protected by U.S. patent 6,168,707.ORION Series A meters and 900A printer are protected by U.S. patents 5,198,093, D334,208 and D346,753.ionplus electrodes and Optimum Results solutions are protected by U.S. patent 5,830,338.ROSS Ultra electrodes are protected by U.S. patent 6,793,787.ORP standard is protected by U.S. patent 6,350,367.No Cal electrodes are protected by U.S. patent 7,276,142.© 2009 <strong>Thermo</strong> Fisher <strong>Scientific</strong> Inc. All rights reserved. All trademarks are the property of <strong>Thermo</strong> Fisher <strong>Scientific</strong> Inc. and its subsidiaries.The specifications, descriptions, drawings, ordering information and part numbers within this document are subject to change without notice.This publication supersedes all previous publications on this subject.

Table of ContentsChapter IGeneral Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1Introduction.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1Features and Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-2Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3Principles of Calibration.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-5Double Known Addition (DKA).. . . . . . . . . . . . . . . . . . . . . . . . . . . . I-5Offline Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-6Fluidics Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-8Two Channel <strong>Analyzer</strong> Configurations.. . . . . . . . . . . . . . . . . . . . . . . . I-10Chapter II<strong>Analyzer</strong> Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-1Unpacking the <strong>Analyzer</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-1Mounting and Plumbing Instructions . . . . . . . . . . . . . . . . . . . . . . . . . II-2Sample Requirements.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-3Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-4Safety Requirements .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-4Warning Labels and Locations.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-5Wiring the <strong>Analyzer</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-6Terminal Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-8Electrode Wiring Assignments.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-9Installation of Reagent and Diffusion Tubing. . . . . . . . . . . . . . . . . . . II-10Installation of New Electrode Cables. . . . . . . . . . . . . . . . . . . . . . . . . II-11Installation of a New <strong>Ammonia</strong> Electrode . . . . . . . . . . . . . . . . . . . . . II-12Installation of the ATC Probe.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II-12Installation of a New Reference Electrode.. . . . . . . . . . . . . . . . . . . . . II-13Chapter III<strong>Analyzer</strong> Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III-1Description of Basic Controls.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III-1Description of Keypad Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III-2Use of the Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III-3Setup Mode Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . III-5Shutdown and Start-Up Procedure.. . . . . . . . . . . . . . . . . . . . . . . . . III-35<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User Guide

Chapter I General InformationThis user guide covers the operation, maintenance and troubleshootingfor the <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> ammonia analyzer, which offersunmatched reliability in analyzing ammonia in boiler feedwater.IntroductionUnlike pH and conductivity measurements, which are affected by otherchemicals that are present in the sample, direct ammonia measurementwith the <strong>2110XP</strong> ammonia analyzer provides accurate measurements witheven the slightest change in ammonia concentration for the best control ofchemical feeds. The system optimizes the fluidic design with our sensingtechnology to provide precise results, simplifying your process with easeand without excessive operating costs.The <strong>2110XP</strong> ammonia analyzer meets all of the criteria for accurateand dependable ammonia monitoring and more. The <strong>2110XP</strong> analyzerincorporates innovative technologies that include:• Premium electrodes• Accurate and precise flow cell design• Marquee help screen• Pump-less reagent addition and DKA calibration system<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong>Markets• Power• Pulp and paper• Agricultural• SemiconductorApplications• RO feedwater monitoring• Seawater-cooled condenser leak detection• Boiler water monitoring• Agricultural water monitoring<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-1

General InformationFeatures and BenefitsThe <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> ammonia analyzer is ideal formeasuring and monitoring the critical ammonia levels in industrial wateror agricultural water applications. With limited maintenance requirementsand low reagent usage, the <strong>2110XP</strong> analyzer can also be used in remotemonitoring applications.• Measurement of ammonia in water using premium <strong>Thermo</strong> <strong>Scientific</strong><strong>Orion</strong> ion selective electrode (ISE) technology.• Accurate and precise measurements in the range of 0 to 10 ppm:• Reliable measurements and a wide measurement range withselectable resolution.• Measures ammonia ion activity in aqueous solutions quickly,accurately and economically.• Premium reference and sensing electrodes:• Superior accuracy and stability over a wide temperature range.• Advanced flow cell design with air stirring:• Automatic sample handling and contamination control with nomoving parts.• Patented scrolling marquee:• Intuitive menu-driven digital user interface.• Data log of previous measurements and calibration:• View measurement, calibration and error history.• Self diagnostics:• Ease of maintainability.• Password protection:• Security and peace of mind for your operation.• Auto-ranging electronics with an easy to read backlit LCD display:• <strong>Analyzer</strong> determines the best range.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-2

General InformationPrinciples of OperationThe sample enters the <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> ammonia analyzerand passes through the inlet valve, bypass/needle valve, inlet filter, pressureregulator, flow meter and into the restrictor tubing. The sample then passesthrough the flow cell manifold into a reagent bottle through a diffusiontubing assembly where pH adjustment takes place. The pH-adjusted samplethen flows back through the manifold into the flow cell as air is introducedfrom the air pump to ensure proper mixing and fast response. The samplethen flows into an atmospheric drain via the diverter valve.K E YFigure I-1<strong>2110XP</strong> Schematic<strong>Analyzer</strong>Reference SolutionAir PumpElectricFluid PathFluid Restrictor TubingAir PathReference Solution PathReagent Overflow PathDiffusion Tubing1 2 3 4 5Power4-20mA OutputRestrictor TubingAir FilterCheckValveAir InletFlow MeterPressurizes Flow Cellto Initiate SiphoningSenseTEMPREFCalibrationPortSafety Drain forReagent OverflowCalibration LevelRegulatorValveMeasure LevelBypass / NeedleValve and FilterCalInlet ValveSampleValveFlow Cell BlockReagent ManifoldValve PositionsCalibration Mode - PUSHSample/Measure Mode - PULLDiffusion TubeReagentReagent BottleMain FeedDrain<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-3

General InformationThe sensing electrode responds logarithmically to changes in the ammoniaion concentration. This response is described by the Nernst equation:Where:E = E o + 2.3 (RT/nF) log (C/C iso )E = measured electrode potential, mVE o = potential, when C equals C iso , mVR = ideal gas constantT = temperature of sample, degrees KnF= valence of ionic species (+1 for ammonia ion)= Faraday’s constantC = effective ammonia ion concentration (activity)C iso = concentration (activity) of ammonia ion where potential E istemperature independent (isopotential point)The above equation indicates that the measured potential varies with bothtemperature and the concentration of the ion of the interest. In order toeliminate error caused by fluctuations in sample temperature, the <strong>2110XP</strong>microprocessor constantly updates temperature corrections from datasupplied by the ATC probe.From the Nernst equation, the theoretical response of a ammonia ionselective electrode to a ten-fold change in concentration at 25 °C is59.16 mV. This is referred to as the electrode slope (S). Most electrodes,however, do not exhibit a theoretical slope. Therefore, the analyzer iscalibrated to determine its actual value. Two standards are used to provideinformation necessary for the microprocessor to compute the actual slopeand E 0 for use during sample analysis.In order to eliminate interference from hydrogen ions, which can becomesignificant when measuring low levels of ammonia, the <strong>2110XP</strong> analyzeradjusts the sample pH. This pH adjustment is accomplished by thepatented passive-diffusion process wherein the sample passes througha length of tubing contained in the reagent bottle. The reagent diffusesthrough the tube wall and mixes with the sample, which adjusts the samplepH to below 4.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-4

General InformationPrinciples ofCalibrationDouble KnownAddition (DKA)Calibration procedures for analytical instruments are important and mustbe performed carefully. The calibration procedure used in the <strong>Thermo</strong><strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> is a variation of Double Known Addition (DKA)using advanced electrode and flow cell technology in combination with thepassive diffusion system. This method has the distinct advantages of beingfast, easy, and accurate.Before calibration begins, the diverter valve is pushed in to divert flow fromthe measure drain, allowing the flow cell to fill.At the beginning of the DKA calibration the actual concentration in thesample is unknown. The analyzer measures the potential (E s ) and storesthis value in the microprocessor. A known amount of standard 1 solutionis added to the flow cell, which increases the concentration (C s ) with acorresponding known amount (dC 1 ). During this process, air is pumpedinto the flow cell, thoroughly mixing sample and standard in a closedloopsystem. The new potential (E 1 ) is measured and stored automaticallywhen stability is reached. Adding standard 2, preferably 10 times moreconcentrated than standard 1, increases the concentration (dC 2 ) in thesample reservoir. Again, the new potential (E 2 ) is measured and storedwhen the reading is stable. Now, we have the following three unknowns:E s =E o + S(T s /298.15) log (C s /C iso )E 1 =E o + S(T 1 /298.15) log [(C s + dC 1 )/C iso ]E 2 =E o + S(T 2 /298.15) log [(C s + dC 1 + dC 2 )/C iso ]S is the Slope at 25 °C (298.15 K)T is the temperature in Kelvin, measured when the potential E is measured.Figure I-2Flow Cell Volume for DKAE s , E 1 , E 2 have been determined during the calibration procedure. Themicroprocessor solves these three equations, to obtain the values of Sand E o . The calibration result is stored for use during online monitoringto convert the measured potential and temperature in the sample intoconcentration values in either ppm or ppb.When the calibration is complete the flow cell drains as the sample flowreturns. The flow cell volume returns to the measurement level. Afterallowing approximately 30 minutes for concentrated calibration solutionto be flushed from the system, the <strong>2110XP</strong> analyzer can begin samplemeasurement again.In addition to Double Known Addition (DKA), the <strong>2110XP</strong> analyzer alsoallows the operator the ability to perform an offline calibration.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-5

General InformationOffline CalibrationThe offline calibration feature of the <strong>2110XP</strong> analyzer allows the operatorto adjust the analyzer to values determined by alternate methods used intheir laboratory such as elemental spectroscopy and ion chromatography.The offline calibration is essentially a one point calibration. To perform anoffline calibration, a sample is taken from the bypass of the analyzer; thesample concentration value is stored in memory; the sample is analyzedby an alternate method of choice; the previously stored reading is adjustedto the lab method result; and the analyzer is then returned to the analysismode. The term “offline calibration” refers only to the fact that a samplefrom <strong>2110XP</strong> analyzer bypass is taken “offline” for laboratory analysis; infact, no downtime is experienced during the procedure and the analyzerremains online throughout.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-6

General InformationFluidics DiagramMode IndicatorScrolling MarqueeLCD DisplayWarning IconStatus IndicatorsKeypadMountingHoleReferenceFillingSolutionAir PumpORION <strong>2110XP</strong><strong>Ammonia</strong>Flow MeterRestructorTubeAssemblyCalibration PortFlow CellReservoirSiphon TubeFlow Cell BlockDiverter ValveCheck ValvePressureRegulatorReagentManifoldBypass/NeedleValveInlet FilterDiffusion TubingAssemblyReagentBottleAdapterAssemblyReagent BottleInlet ValveFigure I-3Fluidics Diagram<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-7

General InformationGlossaryRefer to Figure I-3.Inlet Valve – Accepts the sample stream via 1/4 inch NPTF connector. Theoperator must supply the sample with a pressure between 14 and 100 psig.Inlet Filter – 60 micron stainless steel filter traps particulate matter insample stream.Bypass/Needle Valve – Used to redirect flow in the bypass system.Pressure Regulator – Adjusts flow on the incoming sample stream.Flow Meter – Measures the sample flow rate.Check Valve – Prevents the backflow of sample.Restrictor Tube Assembly – Used in conjunction with the pressureregulator to lower downstream pressure.Reagent Manifold – Directs sample flow in and out of the reagentbottle assembly.Reagent Bottle Adapter Assembly – Connects the reagent bottle assemblyto the manifold.Diffusion Tubing Assembly – Semi-permeable tubing through which thereagent diffuses into the sample.Reagent Bottle – Contains the reagent that lowers the sample pH tobelow 4.Flow Cell – Contains the ammonia sensing electrode, reference electrodeand ATC probe.Diverter Valve – Allows the flow cell reservoir to fill during calibration byforming a closed-loop system.<strong>Ammonia</strong> Electrode – Senses ammonia ions in the sample stream andproduces an electrical potential dependent on the sample concentration.Reference Electrode – Provides a constant reference potential andcompletes the measurement circuit.Reference Electrode Filling Solution Bottle – Provides constant flow ofelectrolyte solution through reference electrode for maximum stability.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-8

General InformationATC Probe – Measures the sample temperature and inputs the data to themicroprocessor for automatic temperature compensation (ATC).Calibration Port – Allows introduction of standards to the sample reservoirduring calibration.Air Pump – Used to mix the sample during both measurementand calibration.LCD Display – Provides digital readouts of concentration, temperature,millivolts and error codes.Keypad – Consists of five mode keys, four prompt indicator lights, twoscroll keys and one key for entering data. Mode and error indicators are alsoincorporated on the keypad.Status Indicator – Two LED lights that illuminate according to currentstatus of the analyzer.Green Light:Yellow Light:Red Light:Indicates that system is in correct working condition.Indicates a warning, system in hold or thatmaintenance is required.Indicates that something is seriously wrong.Note: When either the yellow or red LED is lit, there may be an entry inthe diagnostics mode that indicates the error. The logging feature must beinitiated in the setup mode. Refer to Chapter III, Use of the Setup Modefor instructions.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-9

General InformationTwo Channel <strong>Analyzer</strong>ConfigurationsA pH/ORP module or conductivity module can be added by the operatorto the second channel of the <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> ammoniaanalyzer for the ultimate flexibility in measurement capabilities. The2100 series pH/ORP and conductivity analyzers provide accurate andreliable measurements in ultra pure water as well as the harshest industrialenvironments. Combined with decades of superior <strong>Thermo</strong> <strong>Scientific</strong><strong>Orion</strong> sensor technology, our systems provide rapid results withcomplete stability.Cat. No.2100PH22100CD2DescriptionSecond channel module for pH/ORPSecond channel module for conductivityWhen a pH/ORP module or conductivity module is installed on thesecond channel of the <strong>2110XP</strong> ammonia analyzer, refer to the <strong>Thermo</strong><strong>Scientific</strong> <strong>Orion</strong> 2100 Series pH/ORP <strong>Analyzer</strong> and Conductivity <strong>Analyzer</strong>User Guide for detailed instructions on operating the pH/ORP orconductivity analyzer. Visit www.thermo.com/processwater to downloadany of the 2100 series analyzer user guides.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideI-10

Chapter II <strong>Analyzer</strong> PreparationUnpacking the<strong>Analyzer</strong><strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> analyzers are assembled, tested and packaged withgreat care. Refer to Figure II-1.Report any obvious damage of shipping container to carrier and hold forinspection. The carrier (not <strong>Thermo</strong> Fisher <strong>Scientific</strong>) is responsible for anydamage incurred during shipment.1. Open the outer box. Remove the top two foam corner support pieces.2. Open the inner box. This box should contain the analyzer and ATCtemperature probe, ammonia electrode box, reference electrode box,ammonia standard solutions kit (two 2 oz bottles of 191 ppm ammoniastandard and two x 2 oz bottles of 1920 ppm ammonia standard), theoptions kit and user guide CD.3. Remove the cardboard retaining shell by sliding it over the entiremounting board and the analyzer.4. Carefully remove the entire mounting board with analyzer from theinner box.Note: Do not lift or pull the analyzer by the fluidics or theelectronic components.5. Unbolt the analyzer from the mounting board by removing the fourmounting bolts with a 9/16 wrench. These bolts may be discarded.6. Carefully place the analyzer at a convenient location until properinstallation can be completed.Figure II-1Unpacking the <strong>Analyzer</strong><strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-1

<strong>Analyzer</strong> PreparationMounting andPlumbing InstructionsRefer to the Appendix, Mounting Dimensions section.Warning: Do not connect power prior to the mounting and plumbing ofthe analyzer.Recommendations• Select a site for the analyzer that allows it to be permanently boltedwith ample height for atmospheric drain operation. Be sure that there isready access to the electronic controls, calibration port and electrodes.• A clearance of 15 inches (about 40 cm) must be allowed above theflow cell calibration port. Insert the pipet vertically (not angled) duringthe calibration.• The analyzer location must permit connections to a sample line, drainand AC power supply and any connections for output devices.• The analyzer should be mounted as close to the sampling point aspossible. This ensures the fastest possible response to a changing samplecondition. Refer to the Appendix, Sample Conditions section.• For proper flow cell operation, the analyzer must be installed straightand level upon its mounting location. Failure to level the analyzer maycause poor siphoning in the flow cell.Instructions1. Prepare the mounting holes. Carefully lift the analyzer and bolt it intoplace. Do not lift the analyzer by holding on to any of the plumbing orfluid handling components.2. Connect a waste line to the outlet of the analyzer, which is 3⁄4 NPTmale. The waste line should be connected to a drain of sufficientcapacity, 0.5 inch (1.27 cm) OD is recommended.3. Connect a sample line to the inlet of the analyzer, which is 1⁄4 NPTfemale. It is recommended that a shutoff valve be installed at thesampling point.4. The analyzer must be mounted and leveled vertically for properoperation.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-2

<strong>Analyzer</strong> PreparationSample RequirementsAdditional information is listed in the Appendix, Specifications section.Sample inlet connection – 1/4” NPTF. If particulate matter is present inthe sample, pre-filtration is necessary. The 60 micron stainless steel filterlocated after inlet valve will remove moderate amounts of particulates.Flow rate – 40 mL/minute (nominal).Pressure – 8 to 100 psig. Consult Technical Support for details on samplehandling if the pressure is outside of this range.Temperature – Temperature must be between 5 and 35 °C.<strong>Ammonia</strong> level – <strong>Ammonia</strong> levels are read directly in ppb or ppm, whencalibrated with <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> ammonia standards 1 and 2.Sample alkalinity – Sample alkalinity should be less than 250 ppm CaCO 3equivalent. For higher sample alkalinity, contact Technical Support.Sulfite – Sulfite cannot be present in the sample.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-3

<strong>Analyzer</strong> PreparationElectrical WiringThe warning icon highlights important information that should be strictlyfollowed when using the analyzer for your own safety. Failure to followthese instructions may result in injuries.Warning: Read and observe the following safety recommendations.Safety Requirements• Prior to wiring, a switch or circuit breaker for disconnecting theanalyzer from power supply should be installed.• The switch should be in close proximity to the analyzer and witheasy reach of the user.• The switch should be marked as the disconnecting device forthe analyzer.• To reduce the risk of shock hazard, disconnect the power prior toopening the analyzer.• Before connecting the analyzer to the main, make sure that the voltagelies within either range: 85 to 132 V, 200 mA or 170 to 264 V,100 mA; 50 to 60 Hz AC.• Cutting off the power by disconnecting power source will not reset theanalyzer. This analyzer incorporates a non-volatile memory and willmaintain calibration and settings after power failure. Battery power issupplied to the display for the date and time functions.• If a repair is required, or to arrange Return Material Authorization, callTechnical Support or contact your local authorized dealer.• Installation and wiring of the analyzer may only be carried out inaccordance with applicable local and national codes per this user guide.• Be sure to observe the technical specifications and input ratings.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-4

<strong>Analyzer</strong> PreparationWarning Labelsand LocationsWarning: The following section provides important information thatshould be strictly followed when using the analyzer for your own safety.Failure to follow these instructions may result in injuries.The safety warning icons are used in two locations on the analyzer.• Faceplate – Refer to Figure II-2.Figure II-2Faceplatet Ch 1t Ch 2Ch 1 statusCh 2 status• Power supply – Refer to Figure II-3.Figure II-3Power SupplyInput Power170 - 264V 100mA85 - 132V 200mAFuseNEUTRALGroundPower Supply115V230VFuse Type250V, 200mA Fast Acting250V, 100mA Fast ActingFuse HolderFuseNote: Replace the fuse only with a fuse of same rating.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-5

<strong>Analyzer</strong> PreparationWiring the <strong>Analyzer</strong>Warning: Read and observe the following requirements. If you install thewrong fuse for your system, you could damage the analyzer. Make sure thatyou select the correct fuse rating and discard the additional fuses suppliedin the fuse kit.Required Tools• Options kit – includes fuses, cable glands, conduit fitting and greenscrew terminal.• Phillips head screwdriver.• 2 mm blade flat-head screwdriver.Figure II-4Electronics Enclosurewith Cable GlandsPower CableHole LocationsHinge Pin4 CaptiveScrewsCable GlandsElectrode Cables1. Open the faceplate – loosen the four screws using a Phillips headscrewdriver. The electronics faceplate will open via the hinge pinconnection.2. Remove one or two of the two unused cable glands as required forwiring power cable or auxiliary connections. Power cable optional holelocations are shown in Figure II-4.3. Select and install the appropriate size cable gland or conduit fittingas required.4. Feed the power cable through the conduit or cable glands as required.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-6

<strong>Analyzer</strong> PreparationFigure II-5Terminal Connector LocationTerminal Connector5. Wire the power cable to the green screw terminal connector from theoptions kit. Select correct terminal for hot conductor depending on linevoltage. Refer to Figure II-5 for terminal connector location.6. Plug the terminal connector into the power supply. Refer toFigure II-3.7. Select the correct fuse from the fuse kit. Install by inserting the fuse inthe fuse holder and secure it using the twist and lock method. The fusesare clearly labeled with the appropriate voltages for your system. Referto Figure II-3. Refer to the table below for fuse selection.AC Voltage115V230VFuse Rating200mA, 250V, Fast Acting100mA, 250V Fast Acting<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-7

<strong>Analyzer</strong> PreparationTerminalAssignmentsTerminal Layout Terminal Layout Terminal Layout Terminal Layout1 Sout (mA)sensing signal2 GNDcommon ground3 Tout (mA)temp. signal4 Air pump(ISE only)5 Air pump(ISE only)6 Shield groundfor conductivity9 Relay 1 26 Sensingelectrode10 Relay 1 27 Do notconnect28 Do not connect29 Do not connect11 Relay 2 30 Preamp power12 Relay 2 31 Preamp ground13 Relay 3 32 Shield14 Relay 3 33 Shield7 Do not connect 15 Do not connect 34 Jumper to pin 26when using preamp8 Do not connect 16 Temperature ground17 Temperature drive18 Temperature sense19 Solution ground20 Conductivity drive +21 Conductivity sense +22 Conductivity sense -23 Conductivity drive -24 Reference electrode25 Jumper to pin 24when using preampFigure II-6Terminal Assignments9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 2526271 2 3 4 5 6 7 828 29 30 31 32 33 34<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-8

<strong>Analyzer</strong> PreparationElectrode WiringAssignments<strong>Ammonia</strong> Electrode26 Sensing electrode Connect clear wire33 Shield Connect black wireReference Electrode24 Reference electrode Connect clear wire32 Shield Connect black wire2100TP Temperature Probe16 Temperature ground /thermistor Connect white wire17 Temperature drive /thermistor Connect green wire19 Solution ground Connect red wire2001TM Temperature Probe16 Temperature ground /thermistor Connect white wire17 Temperature drive /thermistor Connect green wire, jumper 17 and 1818 Temperature sense Jumper to 1719 Solution ground Connect red wire2001SC pH Electrode24 Reference electrode Connect black wire26 Sensing electrode Connect clear wire110250 ORP Electrode19 Solution ground Connect black wire24 Reference electrode Connect purple wire26 Sensing electrode Connect coax center wire2002CC and 2002SS Conductivity Probes6 Shield ground for conductivity Connect clear wire16 Temperature ground /thermistor Connect white wire17 Temperature drive /thermistor Connect black wire20 Conductivity drive + Connect orange wire21 Conductivity sense + Connect red wire22 Conductivity sense - Connect green wire23 Conductivity drive - Connect blue wireNote: Only reference the wiring configurations that are applicable to youranalyzer and electrodes.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-9

<strong>Analyzer</strong> PreparationInstallation of Reagentand Diffusion TubingWarning: The reagent is hazardous. Use protective glasses and gloves. Referto the bottle label for precautions and work in a well-ventilated area.Note: Turn off the air pump before beginning this procedure; otherwise,the air pump will splatter the reagent outward as the bottle is removed.1. Remove the thumbnut and slide the bottle adaptor from the flow cell.2. Unscrew the cap and lift the bottle adaptor from the reagent bottle.3. Remove both ends of the old diffusion tubing from the reagent bottleadaptor nipples. Properly dispose of spent reagent and tubing.4. Fit the ends of the new diffusion tubing over the bottle adaptor nipples.5. In a hood or outdoors, carefully remove the cap from a newreagent bottle.6. Make sure that the large O-ring is between the reagent bottle and bottleadaptor. Slide the diffusion tubing loops into the reagent bottle andscrew the bottle adaptor onto the new reagent bottle.7. Ensure that the three small O-rings are in place on the flow cell.8. Re-attach the bottle adaptor/reagent bottle assembly to the flow cellby sliding it onto the screw and tightening the thumbnut. The bottleadaptor can be rotated to allow correct positioning on the analyzer.Figure II-7Reagent Bottle AssemblyReagent Bottle CapFlow Cell Assembly FaceSmall O-ringsThumbnutReagent Bottle AdapterReagent Bottle NippleLarge O-ringReagentDiffusion Tube<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-10

<strong>Analyzer</strong> PreparationInstallation of NewElectrode Cables1. Unpack the electrode cables.2. Feed the tinned wires through the cable gland assemblies with the holes(2 or 1).3. Follow the terminal assignments shown in Figure II-6 for the properelectrode cable wiring location.Ferrite Installation1. Open the ferrite using a flat tip screwdriver to lift the latch ofthe ferrite.2. Feed the cable wires through the center of the ferrite and then loopthe cable wires around the ferrite core and through the center of theferrite again.3. Place the ferrite at the bottom of the analyzer chassis, near its edge.Adjust the ferrite location on the cable so the ferrite is near the top ofthe cable.Figure II-8Ferrite Installation<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-11

<strong>Analyzer</strong> PreparationInstallation of a New<strong>Ammonia</strong> ElectrodeThe <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> ammonia electrode (Cat. No. 100047)must be used in conjunction with the <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> referenceelectrode (Cat. No. 210056).1. Unpack the ammonia electrode (Cat. No. 100047) and carefullyremove the protective cap. Save the cap for future storage ofthe electrode.2. Insert the ammonia electrode into its port in the flow cell cap. Refer toFigure II-9 for the location.3. Plug the electrode cable marked “Sensing” into the top of the electrode.Be sure to push back the black cap to verify a secure connectionbetween the male and female pin connection prior to tightening.4. Tighten the screw cap connection to the cable.Note: Do not twist the cable while tightening the connection. Twistingmay cause damage requiring premature replacement of the cable.5. Wait at least one hour before calibrating the analyzer.Figure II-9Flow Cell CapSensorReferenceATCCalibration PortInstallation of theATC ProbeThe automatic temperature compensation (ATC) probe (Cat. No. 2100TP)is already connected to the correct terminal for temperature upon delivery.1. Insert the ATC probe into its port in the flow cell cap. Refer to FigureII-9 for the location.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-12

<strong>Analyzer</strong> PreparationInstallation of a NewReference Electrode1. Unpack the reference electrode (Cat. No. 210056) and its instructionsheet from the shipping box.2. Carefully remove the protective caps from the bottom and sidearm ofthe reference electrode. Save the caps for future storage of the electrode.3. Shake out as much of the fill solution as possible through the sidearm.Drain the fill solution through the sidearm or use a pipet or syringe.4. While passing the 1/8 inch tubing into electrode sidearm, slide the 1/4inch tubing over the sidearm. The outside tubing should extend 3/8 to1/2 inches over sidearm. Refer to Figure II-10.Figure II-10Reference Electrodewith Filling SolutionReference ElectrodeFilling SolutionGasketTubing Bottle AdaptorSmall 1/8” Tubing InsideBottle CapElectrode SidearmLarge 1/4” TubingCeramic Frit5. Remove the cap and fluid seal from reference electrode fill solutionbottle (Cat. No. 181073). Hold the bottle in an upright position.Check that the rubber gasket is properly aligned, and then connectthe cap end of the tubing assembly to the bottle. The 1/8 inch tubingshould extend into the bottle.6. Hold the reservoir bottle above the electrode with the bottle cap enddown. The electrode should be horizontal with the sidearm pointingup. Gently shake the electrode to allow any trapped air bubbles to riseinto the bottle as the electrode fills with solution.7. Dry off the ceramic frit on the base of the electrode with a lint-freewipe. Squeeze the bottle for a few seconds. A small amount of fillingsolution should bead up on the frit surface, indicating good fillingsolution flow. If no moisture is visible, the electrode is clogged andshould be cleaned or replaced.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-13

<strong>Analyzer</strong> Preparation8. Invert the electrolyte bottle and snap it into the clip. Refer to FigureII-11. Use the pushpin supplied with the reference electrode topuncture three air vents on the bottom of the filling solution bottle.Caution: Failure to vent the filling solution bottle will lead to noisyand drifting output signals.9. Plug the electrode cable marked “Reference” into the top of theelectrode, and tighten the screw cap. Be sure to push back the blackcap to verify a secure connection between the male and female pinconnection prior to tightening.10. Tighten the screw cap connection to the cable.Note: Do not twist the cable while tightening the connection. Twistingmay cause damage requiring premature replacement of the cable.11. Insert the reference electrode into its port in the flow cell cap. ReferFigure II-9 for the location.Figure II-11Reference Mounting ClipClip (on Panel)Air VentsBottle<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideII-14

Description ofBasic ControlsChapter III <strong>Analyzer</strong> OperationBAt Ch 1DCt Ch 2Ch 1 statusCh 2 statusFigure III-1FaceplateEFParameter Location on Display Options DefaultA Mode Indicator Top right corner of displayHOLD, CAL, SETUP, MEASURE,DIAGNOSTICMEASUREBMarquee Display Top left corner of display <strong>Analyzer</strong> provides prompts for operatorusing the scrolling messageTemperature Display Celsius In the measure mode, if an ATC probeis connected the default is the actualmeasured temperature and if no ATCprobe is connected the default is 25 °CCMain Data Display Middle line and bottom line of display ISE board: concentrationpH/mV board: pH or mVConductivity board: conductivity,resistivity, salinity, concentration or TDSDepends on type of board installed andselected measurement parameterDMeasurement UnitsLeft and right side of middle andbottom display linesISE board: ppm or ppb, auto-rangingpH/mV board: pH or mVConductivity board: µS/cm or mS/cm(conductivity), MΩ-cm (resistivity), SAL1or SAL2 in the marquee (salinity), PCT1or PCT2 in the marquee (concentration)and TDS1 or TDS2 in the marquee (TDS)Depends on type of board installed andselected measurement parameterEChannel 1 StatusIndicatorBelow display screen, to the left ofGreen LED indicates that channel is OKOrange LED indicates a channel warningRed LED indicates a channel failureAt initial installation, the red LEDindicates that the electrode or probeneeds to be installed and calibrated.FChannel 2 StatusIndicatorBelow display screen, to the right ofGreen LED indicates that channel is OKOrange LED indicates a channel warningRed LED indicates a channel failureAt initial installation, the red LEDindicates that the electrode or probeneeds to be installed and calibrated.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-1

<strong>Analyzer</strong> OperationDescription ofKeypad Iconst Ch 1t Ch 2Ch 1 statusCh 2 statusFigure III-2Keypad IconsKey Parameter/Mode Action Operational SelectionsEnters calibration mode Calibration mode with operator prompts Depends on type of board installedScrolls up digit numbersScrolls up through a list ofoptions in setup and cal modesEnters setup modeUse to edit numeric valuesUse to select available optionsSystem setup mode at the last parameter usedby the operator0 through 9 selectable by digit, first digit sometimesselectable 0 through 19PASS, DATE, TIME, LOG, RSET, DISP, CH1, CH2, MDL,MEAS, HOLD, TCMP, TADJ, ALRM, mAMP, mADJ, TEST,CAL, PH, COND, DKAMoves to the next digit Use to edit values When moved to final digit, the system will wrap aroundto first digitEnters test modeScroll down digit numbersScroll down through a list ofoptions in setup and cal modesEnters log view modeUse to advance through sequence of displaysDIAGNOSTICS will appear in top right of screenUse to edit numeric valuesUse to select available optionsUse to view data in calibration, measure andstatus logs0 through 9 selectable by digit, first digit sometimesselectable 0 through 19+/- function Enters negative/positive sign when editing numbersEnter functionEnter function (in test mode only)Exit to measure functionLast screen functionDecimal point functionUse to accept value or selection displayed on screenand store value or selection in memoryUse in test mode to display additional informationfor selected menusUse to exit setup or cal modes and enter themeasure modeUse in setup and test modes to return to theprevious screen or menuUse to set the decimal point position in certainmenus with numbers that require a decimal point<strong>Analyzer</strong> automatically enters measure mode when firstturned on and after calibration<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-2

<strong>Analyzer</strong> OperationUse of theSetup ModeBefore the first sample measurements can be taken, the setup mode shouldbe programmed and a successful calibration must be performed by theoperator and stored in the memory of the analyzer.Navigating Tips for theSetup Mode• Press to enter the setup mode.• SETUP appears in the mode indicator screen.• HOLD is displayed while in the setup mode.• The analyzer will enter the setup mode at the last menu that was usedby the operator.• Press and to loop through the menu options.• Press to select the desired menu option and set the menuoption parameters.• Press and to:• Scroll between On and OFF for the selected menu option.• Scroll and set the first digit value to 0 through 19.• Scroll and set the remaining digit values to 0 through 9.• Press to move to the next digit (scroll right) to set each digit value(4 digits maximum).• Press to save the entered parameter for the selected menu option.• Press to exit the current screen and return to the previous screen.• Press to exit the setup mode and return to the measure mode. Ifis pressed, will not return the operator to the setup mode.The operator must reenter the setup mode by pressing .Channel Specific MenuOptions in the Setup ModeIf a single channel analyzer is in use, all of the menu options are accessibleby pressing / in the setup mode. The system will loop throughthe menu options and all of the menu options are in the same level of thesetup mode.If a two channel analyzer is in use, only the general menu options areaccessible by pressing / in the setup mode. The channel 1 andchannel 2 specific menu options must be accessed by selecting the CH1 orCH2 menu options in the setup mode. The channel specific menu optionsare in the second level in setup mode. If a two channel analyzer is in use,make sure to program both the channel 1 and channel 2 menu options inthe setup mode.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-3

<strong>Analyzer</strong> OperationUsing PasswordProtectionThe default password is 0000 – indicates password protection has notbeen activated.System password: Management secured password protection of setupmode and calibration process.Calibration password: Operator secured password for protection ofcalibration process only.If password(s) are activated:• System prompts operator to enter system password:• Marquee: ENTER PASSWORD• Main display top: PASS• Main display bottom: 0000 (flashing)• Correct password – Allows operator to enter setup mode for customprogramming options.• Incorrect password – Password incorrect or not entered correctly.• System password:• Marquee: SYSTEM PASS INCORRECT• Main display: E035• Calibration password:• Marquee: CAL PASS INCORRECT• Main display: E034• Verify password and re-enter it.If password(s) are de-activated:• System enters the setup mode at the last setup menu option used bythe operator.• Marquee: Flashes current menu option• Main display: SEL SCrn<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-4

<strong>Analyzer</strong> OperationSetup Mode OverviewThe setup mode features programmable menu options. The order of themenu options is dependent on the direction the operator scrolls by pressingor . The menu options are listed below by pressing .General Setup ModeMenu OptionsThe following menu options are displayed in the main setup mode of oneand two channel analyzers.PASSSet either of two password options:• System password – Setup settings protected, accessed by authorizedoperators only• Calibration password – Calibration menu data is protected, accessed byauthorized operators only• Default password is 0000 – Disables both passwords• Forgot your password? Contact Technical Support at 1-800-225-1480DATESet the date in US or Europe format:• Enter month, day and year• Default date – System will continue to keep date and time due tobattery back up, operator must set in accordance to local time zone• If the battery is removed, the system will show 01/01/2000TIMESet the time:• Enter hour and minutes in 24 hour format• Default time – System will continue to keep date and time due tobattery back up, operator must set in accordance to local time zone• If the battery is removed the system will show 00:01LOGSet the data logging interval for measure log (calibration and error logs areaccessed in the test mode):• Set the log interval as hour:minute• Default log interval is 00:00 – logging disabled• Minimum log interval is 1 minute, maximum log interval is 99 hoursand 59 minutes<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-5

<strong>Analyzer</strong> OperationRSETReset the analyzer to factory defaults for setup parameters:• Use to troubleshoot the system (a hard reset can be performed if thekeypad and software are not responding, refer to Chapter VI, Resettingthe <strong>Analyzer</strong>)Warning: Resetting the analyzer will lose all stored information includingrelay, logs and calibration settings.DISPSet the automatic lighting options for the backlit display:• AUtO – Brightness will change in response to ambient light source• On – Backlit display is always on• OFF – Backlit display is always off• Default display – AUtO<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-6

<strong>Analyzer</strong> OperationChannel Specific SetupMode Menu OptionsCH1 or CH2If a two channel analyzer is in use, the following setup mode menu optionsare specific to the first channel of the <strong>2110XP</strong> analyzer for ammoniameasurements. When a pH/ORP module or conductivity module isinstalled on the second channel of the <strong>2110XP</strong> analyzer, refer to the <strong>Thermo</strong><strong>Scientific</strong> <strong>Orion</strong> 2100 Series pH/ORP <strong>Analyzer</strong> and Conductivity <strong>Analyzer</strong>User Guide for detailed instructions on the second channel setup modemenu options.The operator must select the channel number in the main setup mode(CH1 or CH2) and the menu options that are relative to the measurementcapability of that channel will be displayed. If a one channel analyzer isbeing used, the CH1 and CH2 menus will not be shown.MEASSet the number of significant digits, mV display option and concentrationunits displayed when in the measure mode:• Set the number of significant digits displayed measure mode• Scroll through 2, 3 or 4 significant digits• Default significant digits – 3• Enable mV values to be displayed on the second line• Scroll between On or OFF• Default mV setting – OFF• Set the displayed concentration units• Scroll through AUtO (automatically ranges from ppb to ppm), PPb(parts per billion, ppb), or PP (parts per million, ppm)• Default displayed concentration units – AUtOHOLDSet the time that the system will remain on hold before the actualmeasurements are displayed after a calibration:• Once the hold time expires, the system implements any programmedchanges to settings in the setup mode• After a calibration, the hold function allows the operator to rinse theelectrodes prior to recording actual measurement values• Default hold time – 30 minutesTADJAdjust the temperature reading from the ATC probe by ± 5.0 °C:• Default adjustment – 0.0 degrees C<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-7

<strong>Analyzer</strong> OperationALRMSet up to three alarms – high, low and an error signaling contact:• Relays 1 and 2 (rLY1, rLY2) are normally open dry contacts used to sethigh and low alarms for measurement values• rLY1 and rLY2 options – OFF, HI, LO• Relay 3 (rLY3) is normally a closed contact that can be dedicated toerrors (will close if power to analyzer is lost), this alarm is influenced bycalibration, errors and offline or hold status• rLY3 options – OFF, CAL, HOLD, Err• Default setting for all alarms – OFFmAMPSet the two analog current outputs (SOUt and tOUt):• Scroll between 4-20 mA or 0-20 mA current signals• The outputs share a common return, but are isolated from the maincircuitry of the analyzer• Default output current – 4-20 mA• Scroll between logarithmic (LOg) and linear (LIn) scale for SOUt• Set the low and high limits for the sensor output (SOUt)• Default – 1.0 ppb (low) and 100 ppb (high)• Set the low and high limits for the temperature output (tOUt)• Default – 5.0 °C (low) and 45.0 °C (high)mADJSet the mA offset adjustment value for the sensor (SOUt) and temperature(tOUt) outputs:• Select the sensor (SOUt) or temperature (tOUt) output• Scroll the numeric offset value and positive or negative offset value• Default mA offset – 00.0 mA<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-8

<strong>Analyzer</strong> OperationTESTTest relays and analog output lines (DIAGNOSTICS will appear in themode indicator):• Method to activate/deactivate relays and outputs to be tested• Verify the accuracy of the analog outputs when used with an externalloop calibrator• Provides the values and settings for the mA output and relays• mA output• 4-20 or 0-20• The sensor (SOUt) and temperature (tOUt) low and high values• Relay status• Set RLY1, RLY2 and RLY3 status to OFF or OnCALSet calibration frequency in hours:• High limit is 19999 hours• Low limit is 00000 hours• Default setting – 720 hoursDKASet values for customized Double Known Addition (DKA):• Programmable for volume (mL) of flow cell, concentration (ppm) andvolume (mL) of standard 1, concentration (ppm) and volume (mL) ofstandard 2 and volume (mL) of additions• Default flow cell volume: 95.0 mL• Default concentration (Std1): 191 ppm• Default volume addition (Std1): 0.5 mL• Default concentration (Std2): 1920 ppm• Default volume addition (Std2): 0.5 mL<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-9

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesSETUP (One Channel <strong>Analyzer</strong>)Pressto enter setup mode• SETUP appears as the mode indicator inthe mode window• HOLD is displayed while in the setupmode• The system will enter the setup mode atthe last saved menu optionPASSDATETIMELOGRSETDISPMEASHOLDTADJALRMmAMPmADJTESTCALDKASEL SCrnThe displayed menuoptions depend onthe measurementcapability of theanalyzer.Press to loop through themenu optionsPress to select the desired menuoption and enter the submenu to customizesetup parameters<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-10

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesSETUP (Two Channel <strong>Analyzer</strong>)Pressto enter setup mode• SETUP appears as the mode indicator inthe mode window• HOLD is displayed while in the setupmode• The system will enter the setup mode atthe last saved menu optionPASSDATETIMELOGRSETDISPCH1MEASHOLDTADJALRMmAMPmADJTESTCALDKASEL SCrnSEL SCrnSEL SCrnSEL SCrnSEL SCrnSEL SCrnSEL SCrnSEL CH1SEL CH1SEL CH1SEL CH1SEL CH1SEL CH1SEL CH1SEL CH1SEL CH1The list of menuoptions shown forCH2 are examplesonly. The displayedmenu options forCH2 depend onthe measurementcapability of thechannel.If only one boardis installed in theanalyzer, CH1 andCH2 will not beshown in the scrollingmarquee and all ofthe menu options willbe listed in the mainsetup mode.CH2MDLHOLDTCMPTADJALRMmAMPmADJTESTCALPHSEL SCrnSEL CH2SEL CH2SEL CH2SEL CH2SEL CH2SEL CH2SEL CH2SEL CH2SEL CH2SEL CH2Press to loop through themenu optionsPress to select the desired menuoption and enter the submenu to customizesetup parameters<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-11

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesPASSPASS(flashing)SELSCrnPressto set new passwords0 0 0 0 SET-UP NEW SYSTEMPASSWORDPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to accept the systempassword and advance to the next screento set the calibration passwordSET-UP NEW SYSTEMPASSWORD0 0 0 0 SET-UP NEW CALIBRATIONPASSWORDPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsSET-UP NEW CALIBRATIONPASSWORDPASS# # # #(first digit flashing)PASS# # # #(change flashing digit)PASS# # # #(first digit flashing)PASS# # # #(change flashing digit)Do not scroll firstdigit above 9Do not scroll firstdigit above 9Press to accept the calibrationpassword and return to the mainsetup modePASS(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-12

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesDATEDATE(flashing)SELSCrnPressto set the dateUS SET USA OR EUROPEAN USPress / to scroll betweenUS and EUrOSET USA OR EUROPEAN(flashing)US or EUrO(flashing)Press to accept the setting andadvance to the next screen01/01/2000 ENTER DATE MM/DD/YYYY(US)Press / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsorENTER DATE DD/MM/YYYY(EUrO)ENTER DATE MM/DD/YYYY(US)orENTER DATE DD/MM/YYYY(EUrO)# # . # # (Month . Day)2 0 # # (Year)or# # . # # (Day . Month)2 0 # # (Year)(first digit flashing)# # . # # (Month . Day)2 0 # # (Year)or# # . # # (Day . Month)2 0 # # (Year)(change flashing digit)Press to accept the date setting andreturn to the main setup modeDATE(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-13

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesTIMETIME(flashing)SELSCrnPressto set the time00:01 ENTER 24HR TIME HOUR/MINUTEPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsENTER 24HR TIME HOUR/MINUTE# # : # # (hour : minute)(first digit flashing)# # : # # (hour : minute)(change flashing digit)Set in 24 hourtime formatPress to accept the time setting andreturn to the main setup modeTIME(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-14

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesLOGLOG(flashing)SELSCrnPressto set the log interval00:00 SET LOG TIME IN HOUR/MINUTEPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsSET LOG TIME IN HOUR/MINUTE# # : # # (hour : minute)LOg(first digit flashing)# # : # # (hour : minute)LOg(change flashing digit)To disable the logenter 0000 for thelog intervalThe minimumlog interval is 1minute and themaximum loginterval is 99hours and59 minutesPress to accept the log setting andreturn to the main setup modeLOG(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-15

<strong>Analyzer</strong> OperationWarning: The reset command will erase all operator settings, logs and calibration data. The analyzer willneed to be set up and calibrated again before it can resume operation.Default Operator Action Scrolling Marquee Main Display NotesRSETRSET(flashing)SELSCrnPressto reset the analyzerPUSH TEST VIEW ENTERTO RESETrSEt?To Reset the <strong>Analyzer</strong>:PressPressPressWhen the reset is complete, the systemwill return to the measure mode. Theoperator will need to re-enter the setupmode to continue programming the setupparameters. Press to return to thesetup mode.PUSH TEST VIEW ENTERTO RESETrSEt?This command resetsall previously setparameters to factorydefault values. Usethis command onlyto set the analyzer tooriginal factory setupvalues.To Abort the Reset:Press to return to the mainsetup modePRESS TEST VIEW ENTERTO RESETrSEt?RSET(flashing)SELSCrnPressto scroll to the next menuWarning: Resetting the analyzer will erase all stored information including relay, logs andcalibration settings.<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-16

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesDISPDISP(flashing)SELSCrnPress to set the lighting option forthe backlit displayAUtO BACK LITE LItEPress / to scroll throughAUtO, OFF and On settingsBACK LITEAUtO(flashing)LItEAUtO, OFF or On(flashing)Press to accept the display settingand return to the main setup modeDISP(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-17

<strong>Analyzer</strong> OperationNote: The following menu options are for analyzers with two modules installed only. If two channels are used,select the channel number in the main setup mode (CH1 or CH2) and additional menu options will be displayed.Default Operator Action Scrolling Marquee Main Display NotesCH1CH1(flashing)SELSCrnCH1 will not beshown in scrollingmarquee if only oneboard is installedPress to set the channel 1 specific menus inthe setup modePress to loop through the channel specificmenu optionsMEAS(flashing)SELCH1Press to select a menu option andcustomize the parameter (refer to the menu optiondisplays that are shown on the following pages fordetailed instructions)CH1(flashing)SELSCrnPressto scroll to the next menuDefault Operator Action Scrolling Marquee Main Display NotesCH2CH2(flashing)SELSCrnCH2 will not beshown in scrollingmarquee if only oneboard is installedPress to set the channel 2 specific menus inthe setup modePress to loop through the channel specificmenu optionsMDL(flashing)SELCH2Press to select a menu option andcustomize the parameter (when a pH/ORP orconductivity board is installed on channel 2, referto the <strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> 2100 Series pH/ORP<strong>Analyzer</strong> and Conductivity <strong>Analyzer</strong> User Guide fordetailed instructions on the menu option displays)CH2(flashing)SELSCrnPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-18

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesMEASMEAS(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto set measure parameters3 SET NUMBER OFSIGNIFICANT DIGITSPress / to scroll through 2,3 and 4SET NUMBER OFSIGNIFICANT DIGITSSIg3(flashing)SIg2, 3 or 4(flashing)Press to accept the setting andadvance to the next screenOFFSHOW MV ON SINGLECHANNEL DISPLAYOFF(flashing)Press / to scroll betweenOFF and OnSHOW MV ON SINGLECHANNEL DISPLAYOFF or On(flashing)Press to accept the setting andadvance to the next screenAUtO SELECT ISE UNIT UnItPress / to scroll throughAUtO, PPb and PPSELECT ISE UNITAUtO(flashing)UnItAUtO, PPb or PP(flashing)PP is used as anabbreviation for ppmPress to accept the setting andreturn to the main setup modeCH1 or CH2(flashing)SELSCrnDisplayed for twochannel analyzerPress to return to the channelspecific menu options in the setup modeAction required fortwo channel analyzerMEAS(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-19

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesHOLDHOLD(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto set the hold time00:30 ENTER HOLD TIMEHOUR/MINUTEPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsENTER HOLD TIMEHOUR/MINUTE# # : # #(first digit flashing)# # : # #(change flashing digit)Press to accept the setting andadvance to the next screenLAStENTER HOLD STATE LASTOR USER VALUELASt(flashing)Press / to scroll betweenLASt and USErENTER HOLD STATE LASTOR USER VALUELASt or USEr(flashing)Press to accept the setting andadvance to the next screen21.0 ENTER FIXED USER VALUEIN mAPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to accept the setting andadvance to the next screenENTER FIXED USER VALUEIN mAOFF HOLD TO 22mA WHEN ERROR OFFPress / to scroll betweenOFF and OnHOLD TO 22mA WHEN ERROR# # . #(first digit flashing)# # . #(change flashing digit)(flashing)OFF or On(flashing)Displayed if USErwas selected inprevious screenAction required ifUSEr was selected inprevious screenAction required ifUSEr was selected inprevious screen<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-20

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesHOLD (cont’d)Press to accept the setting andreturn to the main setup modePress to return to the channelspecific menu options in the setup modeCH1 or CH2(flashing)HOLD(flashing)SELSCrnSELSCrnDisplayed for twochannel analyzerAction required fortwo channel analyzerSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-21

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesTADJTADJ(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPress to set the temperatureadjustment value0.0 C TEMPERATURE ADJUSTMENT AdJPress / to set the first digitPressto move to the next digitPress / to set the value ofthe next digitPress to set a positive or negativetemperature valueTEMPERATURE ADJUSTMENTTEMPERATURE ADJUSTMENT# . # c(first digit flashing)AdJ# . # c(change flashing digit)AdJ- # . # cThe maximumtemperatureadjustment is ± 5.0 °CPress to accept the setting andreturn to the main setup modeCH1 or CH2(flashing)SELSCrnDisplayed for twochannel analyzerPress to return to the channelspecific menu options in the setup modeAction required fortwo channel analyzerTADJ(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-22

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesALRMALRM(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto set the alarmsOFFSELECT ALARM 1 HIGHLOW OR OFFrLY1OFF(flashing)Press / to scroll through OFF,HI and LOSELECT ALARM 1 HIGHLOW OR OFFrLY1OFF, HI or LO(flashing)Press to accept the setting andadvance to the next screen100 ppb Set the HI or LO value for rLY1:Pressto move the decimal pointPress / to set the first digitENTER VALUErLY1# # . # #(change flashing digit)Displayed if HI or LOwas selected for rLY1in previous screenPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to accept the setting andadvance to the next screenAction required if HIor LO was selectedfor rLY1 in previousscreenOFFSELECT ALARM 2 HIGHLOW OR OFFrLY2OFF(flashing)Press / to scroll through OFF,HI and LOSELECT ALARM 2 HIGHLOW OR OFFrLY2OFF, HI or LO(flashing)Press to accept the setting andadvance to the next screen<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-23

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesALRM (cont’d)1 ppm Set the HI or LO value for rLY1:Pressto move the decimal pointPress / to set the first digitENTER VALUErLY2# # . # #(change flashing digit)Displayed if HI orLO was selectedfor rLY2 inprevious screenPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to accept the setting andadvance to the next screenAction requiredif HI or LO wasselected for rLY2in previous screenOFFSELECT CALIBRATION HOLDERROR OR OFFrLY3OFF(flashing)Press / to scroll through OFF,CAL, HOLd and ErrSELECT CALIBRATION HOLDERROR OR OFFrLY3OFF, CAL, HOLd or Err(flashing)Press to accept the setting andreturn to the main setup modeCH1 or CH2(flashing)SELSCrnDisplayed for twochannel analyzerPress to return to the channelspecific menu options in the setup modeAction requiredfor two channelanalyzerALRM(flashing)SELSCrnSEL CH1 or SELCH2 on maindisplay of twochannel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-24

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesmAMPmAMP(flashing)SELSCrnSEL CH1 or SELCH2 on maindisplay of twochannel analyzer4-20Pressto set the analog outputPress / to scroll between4-20 and 0-20SELECT 0-20 OR 4-20 4-20 or 0-20(flashing)Press to accept the setting andadvance to the next screenLOgPress / to scroll betweenLOg and LInSELECT LOG ORLINEAR OUTPUTSOUtLOg or LIn(flashing)Press to accept the setting andadvance to the next screen1 ppb mA SENSOR OUTPUTLOW VALUEPressto move the decimal pointPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to accept the setting andadvance to the next screenmA SENSOR OUTPUTLOW VALUE100 ppb mA SENSOR OUTPUTHIGH VALUEPressto move the decimal pointPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsmA SENSOR OUTPUTHIGH VALUELO# # # . #(first digit flashing)LO# # #. #(change flashing digit)HI# # # . #(first digit flashing)HI# # #. #(change flashing digit)Press to accept the setting andadvance to the next screen<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-25

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesmAMP (cont’d)Press to set the temperatureoutput valueSET TEMP OUTPUT VALUE05.0 C mA TEMP OUTPUT LOW VALUE LOPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsPress to set a positive or negativetemperature valuePress to accept the setting andadvance to the next screenmA TEMP OUTPUT LOW VALUE45.0 C mA TEMP OUTPUT HIGH VALUE HIPress / to set the first digitPressto move to the next digitPress / to set the values ofthe remaining digits and press tomove through the remaining digitsmA TEMP OUTPUT HIGH VALUEtOUt# # . # c(first digit flashing)LO# #.# C(change flashing digit)# # . # c(first digit flashing)HI# # . # c(change flashing digit)Press to accept the setting andreturn to the main setup modePress to return to the channelspecific menu options in the setup modeCH1 or CH2(flashing)mAMP(flashing)SELSCrnSELSCrnDisplayed for twochannel analyzerAction requiredfor two channelanalyzerSEL CH1 or SELCH2 on maindisplay of twochannel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-26

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesmADJmADJ(flashing)SELSCrnSEL CH1 or SELCH2 on maindisplay of twochannel analyzerPress to set the sensor andtemperature mA offset valuesSELECT TEMP OR SENSOROUTPUTSOUt or tOUt(flashing)Press / to scroll betweenSOUt or tOUt and select SOUtSELECT TEMP OR SENSOROUTPUTSOUt(flashing)Press to accept the setting andadvance to the next screen0.00 SENSOR 4-20mA OUTPUTADJUSTMENTPress / to set the sensormA offset valuePress to set a positive or negativesensor mA offsetSENSOR 4-20mA OUTPUTADJUSTMENTAdJ0 . 0 #(last flashing digit)AdJ0 . 0 #(change flashing digit)Press to accept the setting andreturn to the main setup modeCH1 or CH2(flashing)SELSCrnDisplayed for twochannel analyzerPress to return to the channelspecific menu options in the setup modeAction requiredfor two channelanalyzermADJ(flashing)SELSCrnSEL CH1 or SELCH2 on maindisplay of twochannel analyzerPress to set the sensor andtemperature mA offset valuesSELECT TEMP OR SENSOROUTPUTSOUt or tOUt(flashing)Press / to scroll betweenSOUt or tOUt and select tOUtSELECT TEMP OR SENSOROUTPUTtOUt(flashing)<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-27

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesmADJ (cont’d)Press to accept the setting andadvance to the next screen0.00 TEMP 4-20mA OUTPUTADJUSTMENTPress / to set thetemperature mA offset valuePress to set a positive or negativetemperature mA offsetTEMP 4-20mA OUTPUTADJUSTMENTAdJ0 . 0 #(last flashing digit)AdJ0 . 0 #(change flashing digit)Press to accept the setting andreturn to the main setup modePress to return to the channelspecific menu options in the setup modeCH1 or CH2(flashing)mADJ(flashing)SELSCrnSELSCrnDisplayed for twochannel analyzerAction requiredfor two channelanalyzerSEL CH1 or SELCH2 on maindisplay of twochannel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-28

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesTESTTEST(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPress to test the mA outputs (4-20)and relays (rLY)DIAGNOSTICSappears above SETUPin mode windowTo Test tOUt:4-20Press / to scroll between4-20 and rLY settings and select 4-20SELECT mA OR RELAYtESt4 - 20(flashing)Pressto test 4-20 outputsSELECT TEMP OR SENSOROUTPUT4 - 20tOUt or SOUt(flashing)Press / to scroll betweenSOUt and tOUt settings and select tOUtSELECT TEMP OR SENSOROUTPUT4 - 20tOUt(flashing)Pressto display the tOUt low valueActuallow valuedisplayedmA TEMP OUTPUT LOW VALUELO# . # c4.0 mA are sourced atoutput terminal 11Pressto display the tOUt high valueActualhigh valuedisplayedmA TEMP OUTPUT HIGH VALUEHI# . # c20 mA are sourced atoutput terminal 11Press to accept the test and returnto the main setup modeCH1 or CH2(flashing)SELSCrnDisplay for twochannel analyzer onlyPress to return to the channelspecific menu options in the setup modeAction for twochannel analyzer onlyTEST(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPress to test the mA outputs (4-20)and relays (rLY)<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-29

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesTEST (cont’d)To Test SOUt:4-20Press / to scroll between4-20 and rLY settings and select 4-20SELECT mA OR RELAYtESt4 - 20(flashing)Pressto test 4-20 outputsSELECT TEMP OR SENSOROUTPUT4 - 20tOUt or SOUt(flashing)Press / to scroll betweenSOUt and tOUt settings and select SOUtSELECT TEMP OR SENSOROUTPUT4 - 20SOUt(flashing)Pressto display the SOUt low valueActuallow valuedisplayedmA SENSOR OUTPUT LOWVALUELO# . #4.0 mA are sourced atoutput terminal 9Pressto display the SOUt high valueActualhigh valuedisplayedmA SENSOR OUTPUT HIGHVALUEHI#. #20.0 mA are sourcedat output terminal 9Press to accept the test and returnto the main setup modeCH1 or CH2(flashing)SELSCrnDisplay for twochannel analyzer onlyPress to return to the channelspecific menu options in the setup modeAction for twochannel analyzer onlyTEST(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPress to test the mA outputs (4-20)and relays (rLY)<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-30

<strong>Analyzer</strong> OperationDefault Operator Action Scrolling Marquee Main Display NotesTEST (cont’d)To Test rLY:4-20Press / to scroll between4-20 and rLY settings and select rLYSELECT mA OR RELAYtEStrLY(flashing)Pressto test relay outputsActualrLY1 statusPress / to set the rLY1setting OFF or OnUSE ARROWS TO TOGGLERELAY 1rLY1OFF or OnRelay contactaccording to screenindicationPress to accept the rLY1 test andmove to the rLY2 testActualrLY2 statusPress / to set the rLY2setting OFF or OnUSE ARROWS TO TOGGLERELAY 2rLY2OFF or OnRelay contactaccording to screenindicationPress to accept the rLY2 test andmove to the rLY3 testActualrLY3 statusPress / to set the rLY3setting OFF or OnUSE ARROWS TO TOGGLERELAY 3rLY3OFF or OnRelay contactaccording to screenindicationPress to accept the rLY3 test andreturn to the main setup modeCH1 or CH2(flashing)SELSCrnDisplay for twochannel analyzer onlyPress to return to the channelspecific menu options in the setup modeAction for twochannel analyzer onlyTEST(flashing)SELSCrnSEL CH1 or SEL CH2on main display oftwo channel analyzerPressto scroll to the next menu<strong>Thermo</strong> <strong>Scientific</strong> <strong>Orion</strong> <strong>2110XP</strong> <strong>Ammonia</strong> <strong>Analyzer</strong> User GuideIII-31