to get a complimentary download version - (FKM), Verträge und ...

to get a complimentary download version - (FKM), Verträge und ...

to get a complimentary download version - (FKM), Verträge und ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

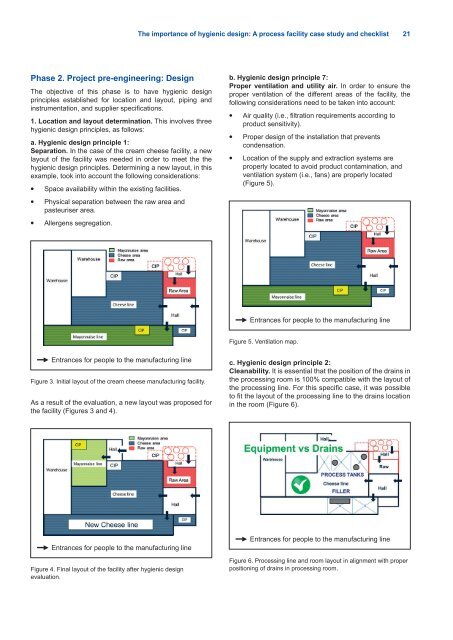

The importance of hygienic design: A process facility case study and checklist 21Phase 2. Project pre-engineering: DesignThe objective of this phase is <strong>to</strong> have hygienic designprinciples established for location and layout, piping andinstrumentation, and supplier specications.1. Location and layout determination. This involves threehygienic design principles, as followsa. Hygienic design principle 1:Separation. In the case of the cream cheese facility, a newlayout of the facility was needed in order <strong>to</strong> meet the thehygienic design principles. Determining a new layout, in thisexample, <strong>to</strong>ok in<strong>to</strong> account the following considerationsSpace availability within the existing facilities.Physical separation between the raw area andpasteuriser area.Allergens segregation.b. Hygienic design principle 7:Proper ventilation and utility air. In order <strong>to</strong> ensure theproper ventilation of the different areas of the facility, thefollowing considerations need <strong>to</strong> be taken in<strong>to</strong> accountAir quality (i.e., ltration requirements according <strong>to</strong>product sensitivity).Proper design of the installation that preventscondensation.Location of the supply and extraction systems areproperly located <strong>to</strong> avoid product contamination, andventilation system (i.e., fans) are properly located(Figure 5). Entrances for people <strong>to</strong> the manufacturing lineFigure 5. Ventilation map. Entrances for people <strong>to</strong> the manufacturing lineFigure 3. Initial layout of the cream cheese manufacturing facility.As a result of the evaluation, a new layout was proposed forthe facility (Figures 3 and 4).c. Hygienic design principle 2:Cleanability. It is essential that the position of the drains inthe processing room is 100% compatible with the layout ofthe processing line. For this specic case, it was possible<strong>to</strong> t the layout of the processing line <strong>to</strong> the drains locationin the room (Figure 6). Entrances for people <strong>to</strong> the manufacturing lineFigure 4. Final layout of the facility after hygienic designevaluation. Entrances for people <strong>to</strong> the manufacturing lineFigure 6. Processing line and room layout in alignment with properpositioning of drains in processing room.