to get a complimentary download version - (FKM), Verträge und ...

to get a complimentary download version - (FKM), Verträge und ...

to get a complimentary download version - (FKM), Verträge und ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

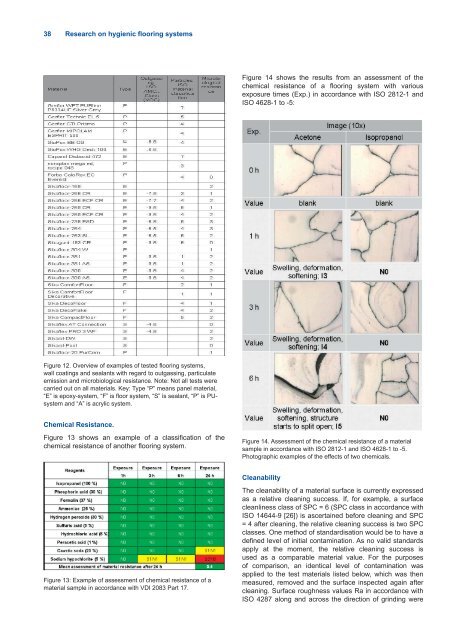

38 Research on hygienic flooring systemsFigure 14 shows the results from an assessment of thechemical resistance of a ooring system with variousexposure times (Exp.) in accordance with ISO 2812-1 andISO 4628-1 <strong>to</strong> -5Figure 12. Overview of examples of tested ooring systems,wall coatings and sealants with regard <strong>to</strong> outgassing, particulateemission and microbiological resistance. Note Not all tests werecarried out on all materials. Key Type “P” means panel material,“E” is epoxy-system, “F” is oor system, “S” is sealant, “P” is PUsystemand “A” is acrylic system.Chemical Resistance.Figure 13 shows an example of a classication of thechemical resistance of another ooring system.Figure 14. Assessment of the chemical resistance of a materialsample in accordance with ISO 2812-1 and ISO 4628-1 <strong>to</strong> -5.Pho<strong>to</strong>graphic examples of the effects of two chemicals.CleanabilityFigure 13 Example of assessment of chemical resistance of amaterial sample in accordance with VDI 2083 Part 17.The cleanability of a material surface is currently expressedas a relative cleaning success. If, for example, a surfacecleanliness class of SPC = 6 (SPC class in accordance withISO 14644-9 [26]) is ascertained before cleaning and SPC= 4 after cleaning, the relative cleaning success is two SPCclasses. One method of standardisation would be <strong>to</strong> have adened level of initial contamination. As no valid standardsapply at the moment, the relative cleaning success isused as a comparable material value. For the purposesof comparison, an identical level of contamination wasapplied <strong>to</strong> the test materials listed below, which was thenmeasured, removed and the surface inspected again aftercleaning. Surface roughness values Ra in accordance withISO 4287 along and across the direction of grinding were