SU-8 Process Training

SU-8 Process Training

SU-8 Process Training

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

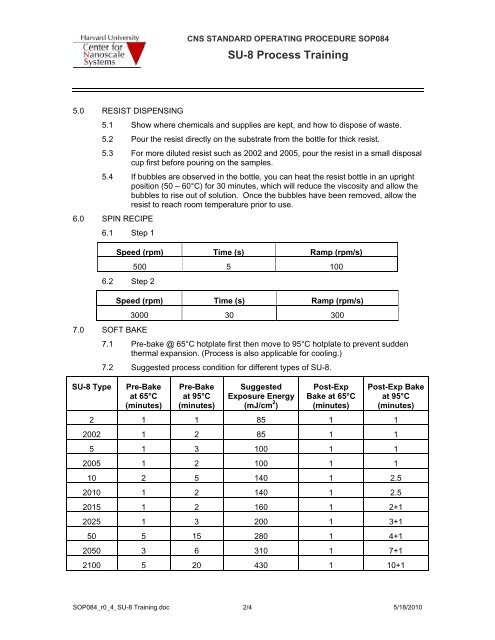

CNS STANDARD OPERATING PROCEDURE SOP084<strong>SU</strong>-8 <strong>Process</strong> <strong>Training</strong>5.0 RESIST DISPENSING5.1 Show where chemicals and supplies are kept, and how to dispose of waste.5.2 Pour the resist directly on the substrate from the bottle for thick resist.5.3 For more diluted resist such as 2002 and 2005, pour the resist in a small disposalcup first before pouring on the samples.5.4 If bubbles are observed in the bottle, you can heat the resist bottle in an uprightposition (50 – 60°C) for 30 minutes, which will reduce the viscosity and allow thebubbles to rise out of solution. Once the bubbles have been removed, allow theresist to reach room temperature prior to use.6.0 SPIN RECIPE6.1 Step 1Speed (rpm) Time (s) Ramp (rpm/s)500 5 1006.2 Step 2Speed (rpm) Time (s) Ramp (rpm/s)3000 30 3007.0 SOFT BAKE7.1 Pre-bake @ 65°C hotplate first then move to 95°C hotplate to prevent suddenthermal expansion. (<strong>Process</strong> is also applicable for cooling.)7.2 Suggested process condition for different types of <strong>SU</strong>-8.<strong>SU</strong>-8 TypePre-Bakeat 65°C(minutes)Pre-Bakeat 95°C(minutes)SuggestedExposure Energy(mJ/cm 2 )Post-ExpBake at 65°C(minutes)Post-Exp Bakeat 95°C(minutes)2 1 1 85 1 12002 1 2 85 1 15 1 3 100 1 12005 1 2 100 1 110 2 5 140 1 2.52010 1 2 140 1 2.52015 1 2 160 1 2+12025 1 3 200 1 3+150 5 15 280 1 4+12050 3 6 310 1 7+12100 5 20 430 1 10+1SOP084_r0_4_<strong>SU</strong>-8 <strong>Training</strong>.doc 2/4 5/18/2010