k-SySTEMS iVF Workstations

k-SySTEMS iVF Workstations

k-SySTEMS iVF Workstations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

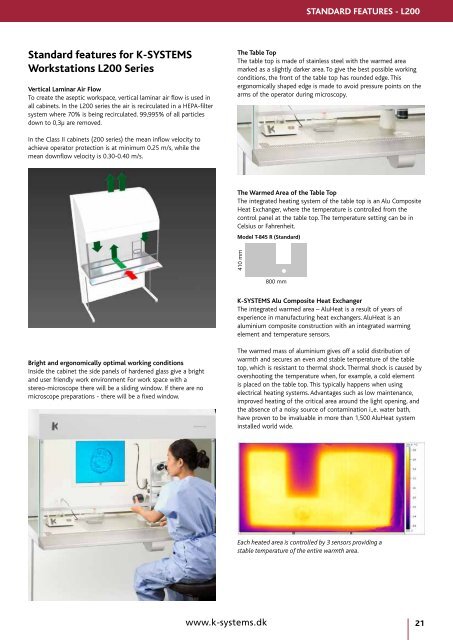

Standard features - L200Standard features for K-Systems<strong>Workstations</strong> L200 SeriesVertical Laminar Air FlowTo create the aseptic workspace, vertical laminar air flow is used inall cabinets. In the L200 series the air is recirculated in a HEPA-filtersystem where 70% is being recirculated. 99,995% of all particlesdown to 0,3µ are removed.The Table TopThe table top is made of stainless steel with the warmed areamarked as a slightly darker area. To give the best possible workingconditions, the front of the table top has rounded edge. Thisergonomically shaped edge is made to avoid pressure points on thearms of the operator during microscopy.In the Class II cabinets (200 series) the mean inflow velocity toachieve operator protection is at minimum 0.25 m/s, while themean downflow velocity is 0.30-0.40 m/s.The Warmed Area of the Table TopThe integrated heating system of the table top is an Alu CompositeHeat Exchanger, where the temperature is controlled from thecontrol panel at the table top. The temperature setting can be inCelsius or Fahrenheit.Model T-845 R (Standard)410 mm800 mmK-SYSTEMS Alu Composite Heat ExchangerThe integrated warmed area – AluHeat is a result of years ofexperience in manufacturing heat exchangers. AluHeat is analuminium composite construction with an integrated warmingelement and temperature sensors.Bright and ergonomically optimal working conditionsInside the cabinet the side panels of hardened glass give a brightand user friendly work environment For work space with astereo-microscope there will be a sliding window. If there are nomicroscope preparations - there will be a fixed window.The warmed mass of aluminium gives off a solid distribution ofwarmth and secures an even and stable temperature of the tabletop, which is resistant to thermal shock. Thermal shock is caused byovershooting the temperature when, for example, a cold elementis placed on the table top. This typically happens when usingelectrical heating systems. Advantages such as low maintenance,improved heating of the critical area around the light opening, andthe absence of a noisy source of contamination i.,e. water bath,have proven to be invaluable in more than 1,500 AluHeat systeminstalled world wide.Each heated area is controlled by 3 sensors providing astable temperature of the entire warmth area.www.k-systems.dk 21