Download - Mintek

Download - Mintek

Download - Mintek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

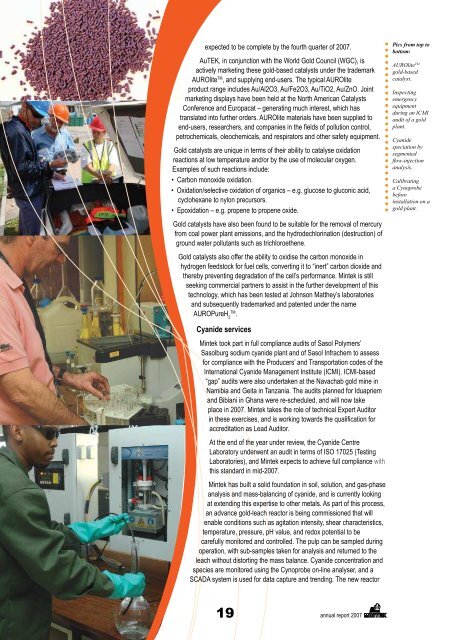

expected to be complete by the fourth quarter of 2007.AuTEK, in conjunction with the World Gold Council (WGC), isactively marketing these gold-based catalysts under the trademarkAUROlite TM , and supplying end-users. The typical AUROliteproduct range includes Au/Al2O3, Au/Fe2O3, Au/TiO2, Au/ZnO. Jointmarketing displays have been held at the North American CatalystsConference and Europacat – generating much interest, which hastranslated into further orders. AUROlite materials have been supplied topetrochemicals, oleochemicals, and respirators and other safety equipment.Gold catalysts are unique in terms of their ability to catalyse oxidationreactions at low temperature and/or by the use of molecular oxygen.Examples of such reactions include:• Carbon monoxide oxidation.• Oxidation/selective oxidation of organics – e.g. glucose to gluconic acid,cyclohexane to nylon precursors.• Epoxidation – e.g. propene to propene oxide.Gold catalysts have also been found to be suitable for the removal of mercuryfrom coal power plant emissions, and the hydrodechlorination (destruction) ofground water pollutants such as trichloroethene.Gold catalysts also offer the ability to oxidise the carbon monoxide inhydrogen feedstock for fuel cells, converting it to “inert” carbon dioxide andthereby preventing degradation of the cell’s performance. <strong>Mintek</strong> is stillseeking commercial partners to assist in the further development of thistechnology, which has been tested at Johnson Matthey’s laboratoriesand subsequently trademarked and patented under the nameAUROPureH 2TM.Pics from top tobottom:AUROlite TMgold-basedcatalyst.Inspectingemergencyequipmentduring an ICMIaudit of a goldplant.Cyanidespeciation bysegmentedanalysis.Calibratinga Cynoprobebeforeinstallation on agold plant.Cyanide services<strong>Mintek</strong> took part in full compliance audits of Sasol Polymers’Sasolburg sodium cyanide plant and of Sasol Infrachem to assessfor compliance with the Producers’ and Transportation codes of theInternational Cyanide Management Institute (ICMI). ICMI-based“gap” audits were also undertaken at the Navachab gold mine inNamibia and Geita in Tanzania. The audits planned for Iduapriemand Bibiani in Ghana were re-scheduled, and will now takeplace in 2007. <strong>Mintek</strong> takes the role of technical Expert Auditoraccreditation as Lead Auditor.At the end of the year under review, the Cyanide CentreLaboratory underwent an audit in terms of ISO 17025 (TestingLaboratories), and <strong>Mintek</strong> expects to achieve full compliance withthis standard in mid-2007.<strong>Mintek</strong> has built a solid foundation in soil, solution, and gas-phaseanalysis and mass-balancing of cyanide, and is currently lookingat extending this expertise to other metals. As part of this process,an advance gold-leach reactor is being commissioned that willenable conditions such as agitation intensity, shear characteristics,temperature, pressure, pH value, and redox potential to becarefully monitored and controlled. The pulp can be sampled duringoperation, with sub-samples taken for analysis and returned to theleach without distorting the mass balance. Cyanide concentration andspecies are monitored using the Cynoprobe on-line analyser, and aSCADA system is used for data capture and trending. The new reactor19annual report 2007