Download - Mintek

Download - Mintek

Download - Mintek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

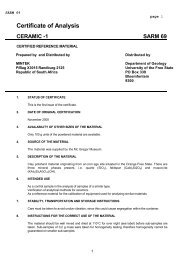

The recent interest shown in this technology by emergingcopper-cobalt producers in central Africa has encouraged <strong>Mintek</strong>to do some work to identify potential scale-up issues. Variousagitators and gas induction systems were investigated, and a highshearimpeller designed and supplied by Outotec was selected forfurther testwork on a 2 m 3 scale to examine the effects of parameterssuch as SO 2and temperature on the process. Optimisation tests remain to be doneon power consumption and various aspects around gas induction.Two smelting campaigns were conducted on discard slag from BCL inBotswana to compare the use of AC and DC furnaces for recoveringnickel and copper. The results showed that both technologies were equallyeffective, and that the company could substantially improve the recoveriesin its slag-cleaning operation by adding reductant to the existing settlingfurnaces.Pics from top tobottom:The Outotechigh-shearimpeller.LaboratoryNicksyn TMreagent insupport of theat Tali Nickel.The thermalMagnesiumProcess demonstrationplant.The <strong>Mintek</strong>-developed nickel synergist (Nicksyn) was evaluated tooptimise nickel recovery and nickel-calcium separation at Tati Nickel inBotswana. Laboratory test work was conducted at <strong>Mintek</strong> on the feed to thenickel solvent-extraction circuit to optimise the combination of the synergistand the Versatic 10 commercial extractant, and the results applied on theActivox® hydrometallurgical demonstration plant at Tati using a 0.5 toncommercial batch of Nicksyn.on the organic phase, which could result in gypsum formation inthe extraction circuit if the feed becomes saturated with calcium.Previously, Tati Nickel minimised the problem by diluting the feedstream with fresh water, but this would increase the size of theproduction. Furthermore, with Versatic 10, the pH of extractioncannot be increased as this causes higher calcium loadings -extraction stages).With the synergistic system, the calcium loading was aboutone-tenth that obtained previously, and gypsum formation canbe completely avoided. The Versatic-Nicksyn combination alsoachieved higher nickel recoveries (99.7 per cent comparedwith about 99.3 per cent) using only four stages. In addition,lower reagent losses were experienced, which can be ascribedto the much lower pH of operation and the reduction in crudeformation.Work continued on the production of titanium-aluminium masteralloys by aluminothermic reduction, and a project is in progressat the University of Cape Town on the fundamental aspects of thetitanium-aluminium-oxygen-carbon-nitrogen system to determinethe best criteria for scale-up.Following a review of the economics of the <strong>Mintek</strong> ThermalMagnesium Process, Anglo American has decided not to pursuecommercialisation, since it is felt that it would not be able tocompete with the low-cost Chinese producers. <strong>Mintek</strong> will continue tolook for opportunities for applying the technology.27annual report 2007