Download - Mintek

Download - Mintek

Download - Mintek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

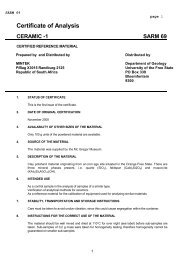

Pics from topto bottom:Small-scalepressureleaching ofa uraniumcontentrate.uraniumleach liquor.Uraniumoxideprecipitation.Hydrophobicitya diamondbearingconcentrate.INDUSTRIAL MINERALSambient and pressure leaching, gold diagnostic leaching,and CIL adsorption, was done for the Buffelsfontein tailingsrecovery project owned by First Uranium, the gold and uraniumsubsidiary of Simmer and Jack Mines. Based in this preliminaryto recover an uranium concentrate, then pressure leaching,solvent extraction and ion exchange using NIMCIX continuousleach residues would be treated in a CIL plant for gold recovery.Also for First Uranium, pilot-scale leaching was conducted on abulk underground sample from the Ezulweni project to producea feed for solid-liquid separation, countercurrent decantation,and ion-exchange testwork. The results will be used to generatedesign criteria for a possible NIMCIX plant. Both these projectsare continuing into 2007.Testwork was completed on the development of the processMalawi, as part of the bankable feasibility study by GRD Minproc.Paladin gave the go-ahead for the development of the project inFebruary 2007, and commissioning is scheduled for the third quarterof 2008. Kayelekera will be Paladin’s second uranium mine in southernAfrica – Langer Heinrich in Namibia, for which <strong>Mintek</strong> conducted2007.<strong>Mintek</strong>’s uranium business continues to grow, and an increasing numberof approaches are being received concerning proposed projects onWitwatersrand-type materials, particularly tailings re-processing for bothuranium and gold. Some of these are potentially very large projects. <strong>Mintek</strong>’sstrength in this area is the comprehensiveness of the services it can provide,from initial investigations up to large scale piloting.During the year, a new laboratory facility for characterising diamonds accordingto their hydrophobicity (response to grease-table recovery) and luminescence(recovery by X-ray methods) was fully commissioned. The laboratory has met withan extremely favourable response form major industry players, including De Beers,SouthernEra, and Bateman, and work on optimising recovery processes has beendone for a number of projects in South Africa and overseas. <strong>Mintek</strong> has engagedan internationally recognised expert in kimberlite petrology and diamond studies,and this project will be expanded in 2007/08 to include diamond characterisation forpurposes of marketing valuation and population discrimination.Ongoing heavy-liquid separation testwork was carried out for De Beers to evaluate<strong>Mintek</strong>’s capabilities in chlorination technology were further developed with thecan handle kilogram-size samples, resulting in a much-improved mass balance.A suite of testwork, including sample characterisation, heavy-liquid separation, shaking-conducted on a sample of bauxite. The aim of the work was to simulate a processingannual report 2007 28