Download - Mintek

Download - Mintek

Download - Mintek

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

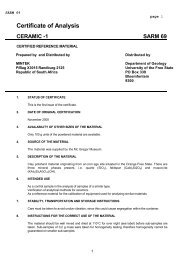

Pics from topto bottom:A Cynoprobewas installedat Polymetallin Russia, andthis will befollowed bya LeachStarcontroller in2007.The measurementcell inthe Cynoprobe.<strong>Mintek</strong>’s ArcMonitor, orArcmon, isan adjunct tothe FurnStarMinstralsystem thatprovidesadditionalinformationabout theconductionbehaviourwithin theburden in submerged-arcfurnaces.AngloGold Ashanti’s Mponeng gold mine, which installed thepurchased a Cynoprobe online cyanide analyser to complementthe control strategy. Four WAD Cynoprobes, which are ableto measure the concentration of both “free” and weak-aciddissociablecyanide, were installed at local gold plants – twoat Beatrix and two at Driefontein. A unit was purchased byAngloGold Ashanti’s Siguiri gold mine in Guinea and willbe commissioned in 2007, and a very successful trial wasconcluded at Geita in Tanzania.A Cynoprobe was installed at Polymetall in Russia, and thiswill be followed by a LeachStar controller in 2007. Cynoprobeswere purchased by Newmont Mining Corporation’s Midasoperation in Nevada and (together with a LeachStar controller)at Waihi in New Zealand. A trial installation was begun at theNewmont/Peñoles La Herradura joint venture in Mexico, andBarrick’s Henty gold mine in western Tasmania, which previouslyhad an older version installed on a trial basis, purchased anupgrade.Further development of the Cynoprobe is under way, withmeasurement range of the instrument to both higher and lowerconcentrations while retaining the accuracy across the range. Inparticular, the monitoring of “post-mixing” aquatic systems requires themeasurement of free cyanide at parts-per-billion levels.The latest version of the FurnStar Minstral TM control strategy forsubmerged-arc furnaces, which includes power optimisation andresistance optimisation modules, was released. FurnStar control wasimplemented at South Africa’s two newest ferrochromium producers – theXstrata-Merafe Lion project and International Ferro Metals’ Buffelsfonteinsmelter – which have a combined annual capacity of 627 000 tons offerrochromium. Lion Ferrochrome, near Steelpoort in Mpumalanga, whichbegan production in September 2006, utilises two 63 MVA furnaces. Thein mid-January, and the second of the two 66 MVA furnaces came on line in earlyFebruary.New FurnStar installations were also completed on a further two furnaces atupgraded with the latest version of the software.<strong>Mintek</strong>’s Arc Monitor, or Arcmon, is an adjunct to the FurnStar Minstral system thatprovides additional information about the conduction behaviour within the burden insubmerged-arc furnaces. Arcmon makes it possible to study the detailed behaviourof the electrical circuit in a submerged-arc furnace in real time. Its ability to distinguishbetween arcing and resistive conduction provides useful information about the burdenof a furnace within its reactive zone, including the carbon balance and the metalbath level. Arcing information can also be used to improve the regulation of electrodeExtensive Arcmon studies have been undertaken on the electrical conduction in siliconmetal, ferrosilicon and ferrochromium furnaces, and during 2006 a further trial was2007.annual report 2007 34