Heavy metal adsorption on iron oxide and iron oxide-coated silica ...

Heavy metal adsorption on iron oxide and iron oxide-coated silica ...

Heavy metal adsorption on iron oxide and iron oxide-coated silica ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

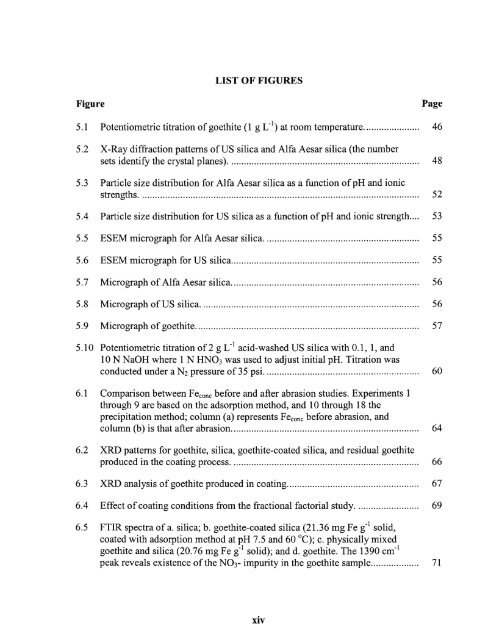

LIST OF FIGURESFigurePage5.1 Potentiometric titrati<strong>on</strong> of goethite (1 g L-1 ) at room temperature. 465.2 X-Ray diffracti<strong>on</strong> patterns of US <strong>silica</strong> <strong>and</strong> Alfa Aesar <strong>silica</strong> (the numbersets identify the crystal planes). 485.3 Particle size distributi<strong>on</strong> for Alfa Aesar <strong>silica</strong> as a functi<strong>on</strong> of pH <strong>and</strong> i<strong>on</strong>icstrengths. 525.4 Particle size distributi<strong>on</strong> for US <strong>silica</strong> as a functi<strong>on</strong> of pH <strong>and</strong> i<strong>on</strong>ic strength 535.5 ESEM micrograph for Alfa Aesar <strong>silica</strong>. 555.6 ESEM micrograph for US <strong>silica</strong> 555.7 Micrograph of Alfa Aesar <strong>silica</strong>. 565.8 Micrograph of US <strong>silica</strong>. 565.9 Micrograph of goethite. 575.10 Potentiometric titrati<strong>on</strong> of 2 g L -1 acid-washed US <strong>silica</strong> with 0.1, 1, <strong>and</strong>10 N NaOH where 1 N HNO3 was used to adjust initial pH. Titrati<strong>on</strong> wasc<strong>on</strong>ducted under a N2 pressure of 35 psi. 606.1 Comparis<strong>on</strong> between Fe. before <strong>and</strong> after abrasi<strong>on</strong> studies. Experiments 1through 9 are based <strong>on</strong> the <str<strong>on</strong>g>adsorpti<strong>on</strong></str<strong>on</strong>g> method, <strong>and</strong> 10 through 18 theprecipitati<strong>on</strong> method; column (a) represents Fec<strong>on</strong>c before abrasi<strong>on</strong>, <strong>and</strong>column (b) is that after abrasi<strong>on</strong> 646.2 XRD patterns for goethite, <strong>silica</strong>, goethite-<strong>coated</strong> <strong>silica</strong>, <strong>and</strong> residual goethiteproduced in the coating process. 666.3 XRD analysis of goethite produced in coating 676.4 Effect of coating c<strong>on</strong>diti<strong>on</strong>s from the fracti<strong>on</strong>al factorial study. 696.5 FTIR spectra of a. <strong>silica</strong>; b. goethite-<strong>coated</strong> <strong>silica</strong> (21.36 mg Fe g -1 solid,<strong>coated</strong> with <str<strong>on</strong>g>adsorpti<strong>on</strong></str<strong>on</strong>g> method at pH 7.5 <strong>and</strong> 60 °C); c. physically mixedgoethite <strong>and</strong> <strong>silica</strong> (20.76 mg Fe g -1 solid); <strong>and</strong> d. goethite. The 1390 cm -1peak reveals existence of the NO 3- impurity in the goethite sample 71xiv