Single Phase AC Induction Squirrel Cage Motors - Aerovent

Single Phase AC Induction Squirrel Cage Motors - Aerovent

Single Phase AC Induction Squirrel Cage Motors - Aerovent

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

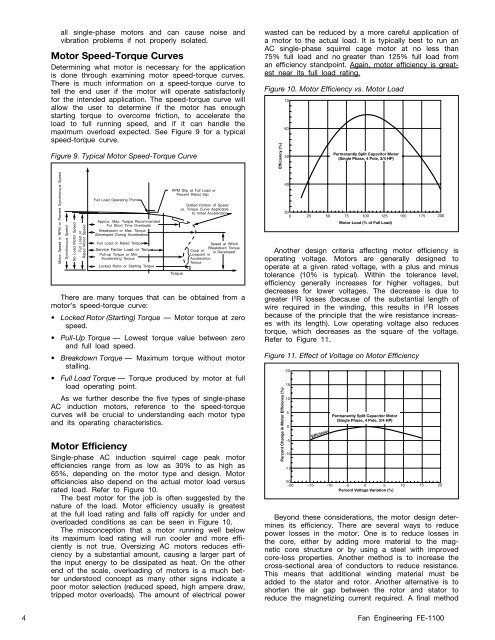

all single-phase motors and can cause noise andvibration problems if not properly isolated.Motor Speed-Torque CurvesDetermining what motor is necessary for the applicationis done through examining motor speed-torque curves.There is much information on a speed-torque curve totell the end user if the motor will operate satisfactorilyfor the intended application. The speed-torque curve willallow the user to determine if the motor has enoughstarting torque to overcome friction, to accelerate theload to full running speed, and if it can handle themaximum overload expected. See Figure 9 for a typicalspeed-torque curve.Figure 9. Typical Motor Speed-Torque CurveMotor Speed in RPM or Percent Synchronous SpeedSynchronous SpeedNo Load Motor SpeedFull Load orRated Motor SpeedFull Load Operating PointApprox. Max. Torque RecommendedFor Short Time OverloadsBreakdown or Max. Torque(Developed During Acceleration)RPM Slip at Full Load orPercent Rated SlipTorqueDotted Portion of Speedvs. Torque Curve Applicableto Initial Acceleration}Full Load or Rated TorqueSpeed at WhichService Factor Load or TorqueBreakdown TorqueCusp or is DevelopedPull-up Torque or Min.Lowpoint inAccelerating Torque } AccelerationTorqueLocked Rotor or Starting TorqueThere are many torques that can be obtained from amotor’s speed-torque curve:• Locked Rotor (Starting) Torque — Motor torque at zerospeed.• Pull-Up Torque — Lowest torque value between zeroand full load speed.• Breakdown Torque — Maximum torque without motorstalling.• Full Load Torque — Torque produced by motor at fullload operating point.As we further describe the five types of single-phase<strong>AC</strong> induction motors, reference to the speed-torquecurves will be crucial to understanding each motor typeand its operating characteristics.Motor Efficiency<strong>Single</strong>-phase <strong>AC</strong> induction squirrel cage peak motorefficiencies range from as low as 30% to as high as65%, depending on the motor type and design. Motorefficiencies also depend on the actual motor load versusrated load. Refer to Figure 10.The best motor for the job is often suggested by thenature of the load. Motor efficiency usually is greatestat the full load rating and falls off rapidly for under andoverloaded conditions as can be seen in Figure 10.The misconception that a motor running well belowits maximum load rating will run cooler and more efficientlyis not true. Oversizing <strong>AC</strong> motors reduces efficiencyby a substantial amount, causing a larger part ofthe input energy to be dissipated as heat. On the otherend of the scale, overloading of motors is a much betterunderstood concept as many other signs indicate apoor motor selection (reduced speed, high ampere draw,tripped motor overloads). The amount of electrical powerwasted can be reduced by a more careful application ofa motor to the actual load. It is typically best to run an<strong>AC</strong> single-phase squirrel cage motor at no less than75% full load and no greater than 125% full load froman efficiency standpoint. Again, motor efficiency is greatestnear its full load rating.Figure 10. Motor Efficiency vs. Motor LoadEfficiency (%)70605040Permanently Split Capacitor Motor(<strong>Single</strong> <strong>Phase</strong>, 4 Pole, 3/4 HP)300 25 50 75 100 125 150 175 200Motor Load (% of Full Load)Another design criteria affecting motor efficiency isoperating voltage. <strong>Motors</strong> are generally designed tooperate at a given rated voltage, with a plus and minustolerance (10% is typical). Within the tolerance level,efficiency generally increases for higher voltages, butdecreases for lower voltages. The decrease is due togreater I 2 R losses (because of the substantial length ofwire required in the winding, this results in I 2 R lossesbecause of the principle that the wire resistance increaseswith its length). Low operating voltage also reducestorque, which decreases as the square of the voltage.Refer to Figure 11.Figure 11. Effect of Voltage on Motor EfficiencyPercent Change in Motor Efficiency (%)20151050-5-10-15EfficiencyPermanently Split Capacitor Motor(<strong>Single</strong> <strong>Phase</strong>, 4 Pole, 3/4 HP)-30-20 -15 -10 -5 0 5 10 15 20Percent Voltage Variation (%)Beyond these considerations, the motor design determinesits efficiency. There are several ways to reducepower losses in the motor. One is to reduce losses inthe core, either by adding more material to the magneticcore structure or by using a steel with improvedcore-loss properties. Another method is to increase thecross-sectional area of conductors to reduce resistance.This means that additional winding material must beadded to the stator and rotor. Another alternative is toshorten the air gap between the rotor and stator toreduce the magnetizing current required. A final method4 Fan Engineering FE-1100