Single Phase AC Induction Squirrel Cage Motors - Aerovent

Single Phase AC Induction Squirrel Cage Motors - Aerovent

Single Phase AC Induction Squirrel Cage Motors - Aerovent

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

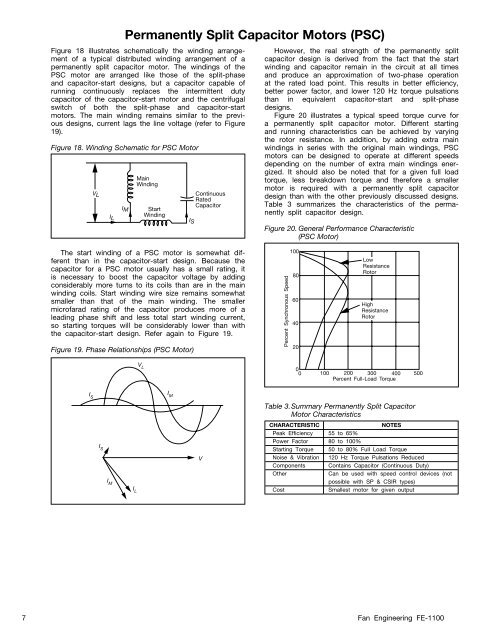

Permanently Split Capacitor <strong>Motors</strong> (PSC)Figure 18 illustrates schematically the winding arrangementof a typical distributed winding arrangement of apermanently split capacitor motor. The windings of thePSC motor are arranged like those of the split-phaseand capacitor-start designs, but a capacitor capable ofrunning continuously replaces the intermittent dutycapacitor of the capacitor-start motor and the centrifugalswitch of both the split-phase and capacitor-startmotors. The main winding remains similar to the previousdesigns, current lags the line voltage (refer to Figure19).Figure 18. Winding Schematic for PSC MotorVLILIMMainWindingStartWindingISContinuousRatedCapacitorHowever, the real strength of the permanently splitcapacitor design is derived from the fact that the startwinding and capacitor remain in the circuit at all timesand produce an approximation of two-phase operationat the rated load point. This results in better efficiency,better power factor, and lower 120 Hz torque pulsationsthan in equivalent capacitor-start and split-phasedesigns.Figure 20 illustrates a typical speed torque curve fora permanently split capacitor motor. Different startingand running characteristics can be achieved by varyingthe rotor resistance. In addition, by adding extra mainwindings in series with the original main windings, PSCmotors can be designed to operate at different speedsdepending on the number of extra main windings energized.It should also be noted that for a given full loadtorque, less breakdown torque and therefore a smallermotor is required with a permanently split capacitordesign than with the other previously discussed designs.Table 3 summarizes the characteristics of the permanentlysplit capacitor design.Figure 20. General Performance Characteristic(PSC Motor)The start winding of a PSC motor is somewhat differentthan in the capacitor-start design. Because thecapacitor for a PSC motor usually has a small rating, itis necessary to boost the capacitor voltage by addingconsiderably more turns to its coils than are in the mainwinding coils. Start winding wire size remains somewhatsmaller than that of the main winding. The smallermicrofarad rating of the capacitor produces more of aleading phase shift and less total start winding current,so starting torques will be considerably lower than withthe capacitor-start design. Refer again to Figure 19.1008060402000I I S MI SFigure 19. <strong>Phase</strong> Relationships (PSC Motor)Percent Synchronous SpeedLowResistanceRotorHighResistanceRotor100 200 300 400 500Percent Full-Load TorqueTable 3. Summary Permanently Split CapacitorMotor CharacteristicsI MI LV LVCHAR<strong>AC</strong>TERISTICNOTESPeak Efficiency 55 to 65%Power Factor 80 to 100%Starting Torque 50 to 80% Full Load TorqueNoise & Vibration 120 Hz Torque Pulsations ReducedComponents Contains Capacitor (Continuous Duty)OtherCan be used with speed control devices (notpossible with SP & CSIR types)CostSmallest motor for given output7 Fan Engineering FE-1100