reduce costs and improve control with enviro-tec® ssr based, time ...

reduce costs and improve control with enviro-tec® ssr based, time ...

reduce costs and improve control with enviro-tec® ssr based, time ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

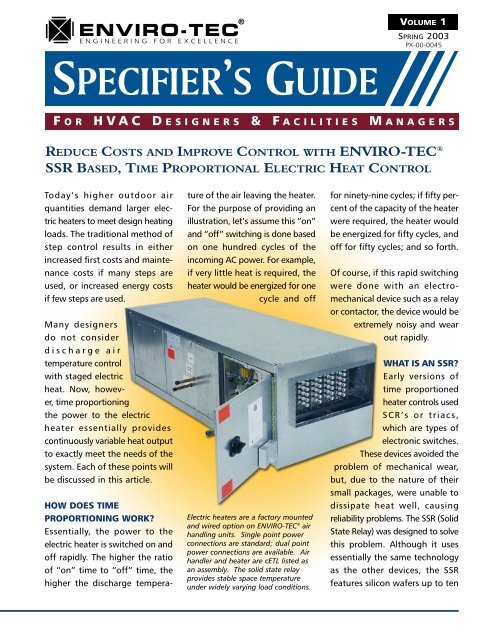

VOLUME 1SPRING 2003PX-00-0045F OR HVAC DESIGNERS & FACILITIES M ANAGERSREDUCE COSTS AND IMPROVE CONTROL WITH ENVIRO-TEC ®SSR BASED, TIME PROPORTIONAL ELECTRIC HEAT CONTROLToday’s higher outdoor airquantities dem<strong>and</strong> larger electricheaters to meet design heatingloads. The traditional method ofstep <strong>control</strong> results in eitherincreased first <strong>costs</strong> <strong>and</strong> maintenance<strong>costs</strong> if many steps areused, or increased energy <strong>costs</strong>if few steps are used.Many designersdo not considerdischarge airtemperature <strong>control</strong><strong>with</strong> staged electricheat. Now, however,<strong>time</strong> proportioningthe power to the electricheater essentially providescontinuously variable heat outputto exactly meet the needs of thesystem. Each of these points willbe discussed in this article.HOW DOES TIMEPROPORTIONING WORK?Essentially, the power to theelectric heater is switched on <strong>and</strong>off rapidly. The higher the ratioof “on” <strong>time</strong> to “off” <strong>time</strong>, thehigher the discharge temperatureof the air leaving the heater.For the purpose of providing anillustration, let’s assume this “on”<strong>and</strong> “off” switching is done <strong>based</strong>on one hundred cycles of theincoming AC power. For example,if very little heat is required, theheater would be energized for onecycle <strong>and</strong> offElectric heaters are a factory mounted<strong>and</strong> wired option on ENVIRO-TEC ® airh<strong>and</strong>ling units. Single point powerconnections are st<strong>and</strong>ard; dual pointpower connections are available. Airh<strong>and</strong>ler <strong>and</strong> heater are cETL listed asan assembly. The solid state relayprovides stable space temperatureunder widely varying load conditions.for ninety-nine cycles; if fifty percentof the capacity of the heaterwere required, the heater wouldbe energized for fifty cycles, <strong>and</strong>off for fifty cycles; <strong>and</strong> so forth.Of course, if this rapid switchingwere done <strong>with</strong> an electromechanicaldevice such as a relayor contactor, the device would beextremely noisy <strong>and</strong> wearout rapidly.WHAT IS AN SSR?Early versions of<strong>time</strong> proportionedheater <strong>control</strong>s usedSCR’s or triacs,which are types ofelectronic switches.These devices avoided theproblem of mechanical wear,but, due to the nature of theirsmall packages, were unable todissipate heat well, causingreliability problems. The SSR (SolidState Relay) was designed to solvethis problem. Although it usesessentially the same technologyas the other devices, the SSRfeatures silicon wafers up to ten

<strong>time</strong>s larger than the older devices<strong>with</strong> equal current ratios, <strong>and</strong>heat dissipating areas over twenty<strong>time</strong>s the size of the olderdevices. The latest versions ofSSR’s feature three phase, 480volt <strong>control</strong> in a single package,greatly reducing the number ofconnections required, whichfurther enhances reliability.Another advantage of the SSR iszero voltage switching. In otherwords, the power to the heater isonly switched on <strong>and</strong> off when theAC waveform is crossing zerovolts.This switching method not onlygreatly <strong>reduce</strong>s stress on systemcomponents, it also avoids voltagetransients which are generatedwhen the power is switched on oroff at the peak of the AC voltage.Most older <strong>time</strong> proportioned<strong>control</strong>s, <strong>and</strong> many current ones,do not use this switching method.DOES TIME PROPORTIONEDHEAT REDUCE COSTS ANDIMPROVE CONTROL?With only a limited number ofsteps of electric heat, chances arethat the heating requirements ata given point in <strong>time</strong> will notmatch the incremental capacity ofthe number of stages available. Forinstance, in the case of a twostep heater, if the actual outputrequirement of the heater is sixtypercent, the second stage willneed to be switched on (onehundred percent output) <strong>and</strong> off(fifty percent output) in an effortto maintain the desired temperature<strong>control</strong>. Consequently, thespace or discharge temperature(depending on the heater application)is mostly either too warmor too cool. Not only is energywasted when the space is toowarm, but, since it takes moreenergy to heat a space to a desiredtemperature than to maintain itat the temperature, energy iswasted when the space is reheatedafter cooling. This energy losscan be <strong>reduce</strong>d by switching thesteps on <strong>and</strong> off more rapidly,but, as discussed early, this <strong>reduce</strong>sthe life of the system components.Also, occupants may findthe “clicking” associated <strong>with</strong>energizing <strong>and</strong> de-energizingmagnetic contactors annoying.VERTICAL HI-RISE FAN COIL ELECTRIC HEATElectric heat is available in a wide variety of kW<strong>and</strong> voltage configurations. Options include doorinterlock disconnects <strong>and</strong> low voltage <strong>control</strong>s.Controls <strong>and</strong> electric heat components on allENVIRO-TEC ® products are factory mounted <strong>and</strong>wired, <strong>and</strong> ETL listed as an assembly.DIRECT DRIVE BLOWER COIL ELECTRIC HEATPremium quality materials such as stainless steelelement hardware, Ni-Chrome wire elements, <strong>and</strong>high temperature rated wiring exceed typicalindustry quality st<strong>and</strong>ards. Control <strong>and</strong> electricheat configurations on all ENVIRO-TEC ® productsare <strong>with</strong> single point power <strong>and</strong> are ETL listed asan assembly.Specifier’s Guide Volume 1 • ©2003 Environmental Technologies, Inc.

Adding more steps will also help<strong>reduce</strong> this energy loss, but at agreater first cost <strong>and</strong> increasedmaintenance due to an increasednumber of components. The costof <strong>time</strong> proportioned <strong>control</strong> isactually less than four steps of<strong>control</strong> using magnetic contactors,or two steps of <strong>control</strong> usingmercury contactors. Also, mostDDC <strong>control</strong>lers cannot h<strong>and</strong>lemore than two or three steps ofelectric heat on fan poweredterminals.options include wall or ductthermostats, or inputs for <strong>control</strong>by others. Input options include0-135Ω, 4-20 mA, 2-10 VDC,6-9 VDC or PWM (pulse widthmodulation).For further information on this orany other product, contact yourENVIRO-TEC ® representative or visitwww.<strong>enviro</strong>-tec.com.WHAT OPTIONS DOESENVIRO-TEC ® OFFER WITH ITSTIME PROPORTIONEDELECTRIC HEAT?ENVIRO-TEC ® Time ProportionedElectric Heat is available in eithersingle or three phase <strong>with</strong> linevoltages up to 480 VAC. InputSSR ELECTRIC HEAT CONTROLLER AND RELAYHORIZONTAL FAN COILELECTRICAL ENCLOSUREThe bottom hinged electricalenclosure provides access toa spacious electrical compartment.This compartmenthouses all electric heat <strong>and</strong><strong>control</strong> components. Terminalstrips are furnished for simplepower <strong>and</strong><strong>control</strong> wiringconnections.Multipleknockouts allowwiring entriesfrom eitherside of thecompartment.Specifier’s Guide Volume 1

ENVIRO-TEC ® S INGLE Z ONE E LECTRIC H EAT VAVC ORRECTS C OMMON I NDUSTRY H EATER P ROBLEMSThe SDR-EH breaks new ground in singleduct VAV electric heater design. Thepatented FlowStar TM sensor permitsmodulation to lower airflow levels than allother sensors in the industry. This minimizesthe energy expended for heat inmany applications. The FlowStar probeprovides a <strong>control</strong> signal that is 2.75 <strong>time</strong>sthe signal provided by the traditional Pitottube sensor.Historically, heater elements placeddownstream of a VAV damperhave experienced two majorproblems:• Elements fail prematurely due tohot spots resulting from anuneven air velocity profile overthe heater face• Heaters suffer rapid nuisancecycling of the contactors <strong>and</strong>elements because the airflowswitch probe is located on thelow pressure (downstreamside) of the VAV damperENVIRO-TEC‘s unique electric heatVAV terminal, the SDR-EH, solvesthese problems. The heaterelements are located midwaybetween the air inlet <strong>and</strong> thedamper. This design providesuniform airflow over the face ofthe electric heater at all damperpositions. Element life is extended,reducing repair cost,discomfort, <strong>and</strong> inconvenience.With the heater elements locatedon the high pressure side ofthe VAV damper, the airflowpressure switch receives areliable pressure signal even atminimum damper positions. Thisarrangement provides greatersafety, as well as enhancedreliability.The SDR-EH design permitstremendous flexibility whenselecting KW, voltage, phase,balanced or unbalanced circuiting<strong>and</strong> method of <strong>control</strong>.With over 100,000 of these electricheat terminals installed, thisdesign concept is “tried <strong>and</strong> true.”The SDR-EH from ENVIRO-TEC ®raises the st<strong>and</strong>ard of excellencein electric heat VAV design.The FlowStar TM probe is visible in the inlet of theSDR-EH. The elements, partially removed for thisphoto, are midway between the inlet <strong>and</strong> damper.The outlet end of the SDR-EH reveals the VAVdamper. Heater elements are well upstream of thedamper in an area of uniform airflow.Specifier’s Guide Volume 1 • ©2003 Environmental Technologies, Inc.