SMT 400 Temperature Differential Controller

SMT 400 Temperature Differential Controller

SMT 400 Temperature Differential Controller

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

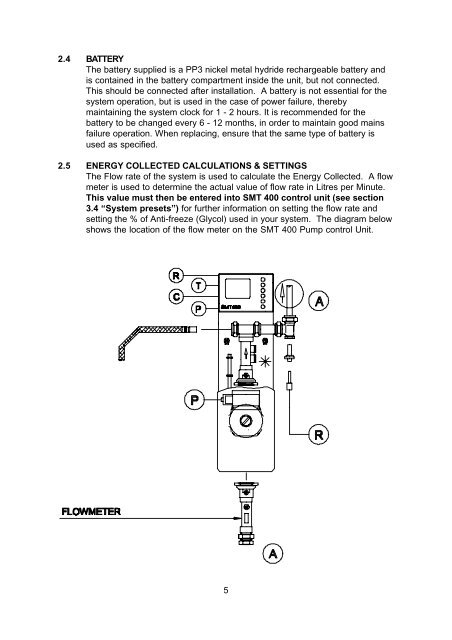

2.4 BATTERYThe battery supplied is a PP3 nickel metal hydride rechargeable battery andis contained in the battery compartment inside the unit, but not connected.This should be connected after installation. A battery is not essential for thesystem operation, but is used in the case of power failure, therebymaintaining the system clock for 1 - 2 hours. It is recommended for thebattery to be changed every 6 - 12 months, in order to maintain good mainsfailure operation. When replacing, ensure that the same type of battery isused as specified.2.5 ENERGY COLLECTED CALCULATIONS & SETTINGSThe Flow rate of the system is used to calculate the Energy Collected. A flowmeter is used to determine the actual value of flow rate in Litres per Minute.This value must then be entered into <strong>SMT</strong> <strong>400</strong> control unit (see section3.4 “System presets”) for further information on setting the flow rate andsetting the % of Anti-freeze (Glycol) used in your system. The diagram belowshows the location of the flow meter on the <strong>SMT</strong> <strong>400</strong> Pump control Unit.5